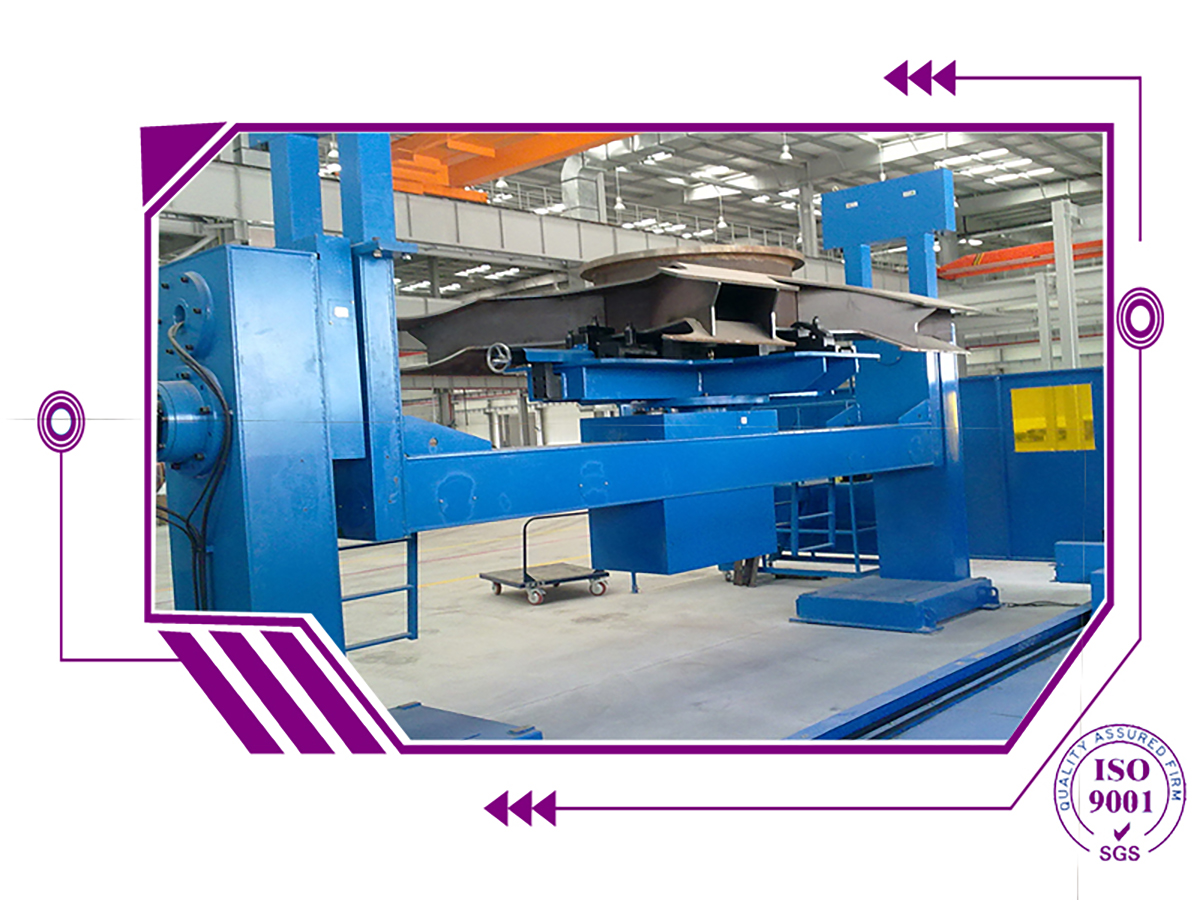

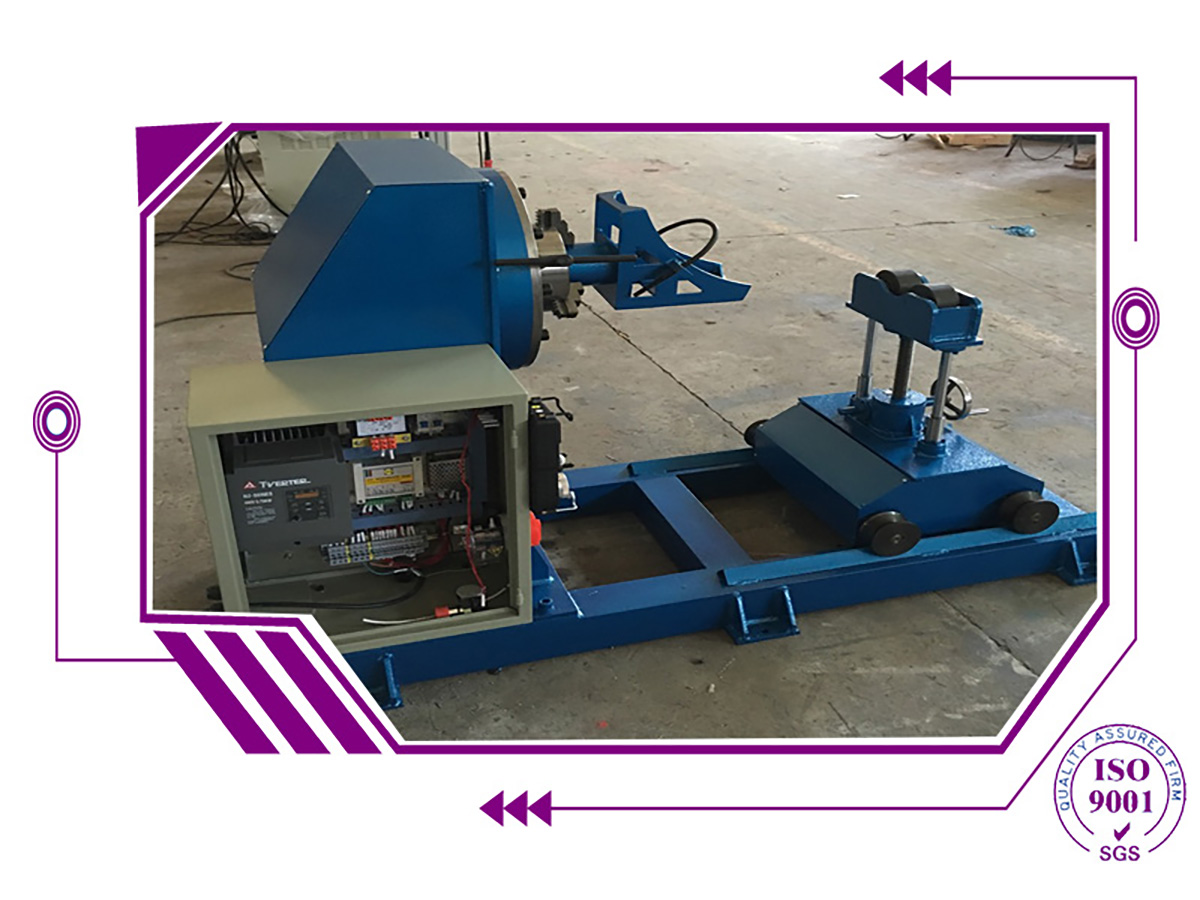

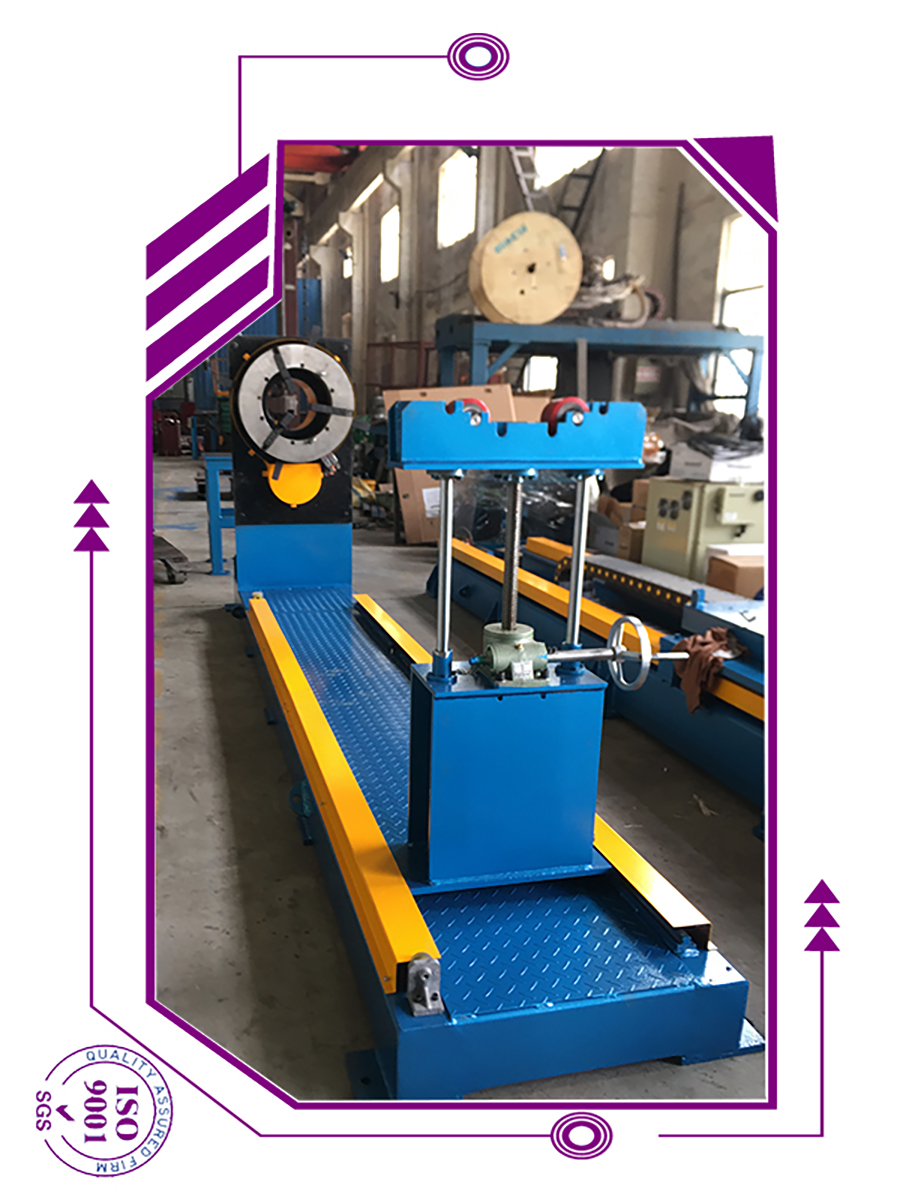

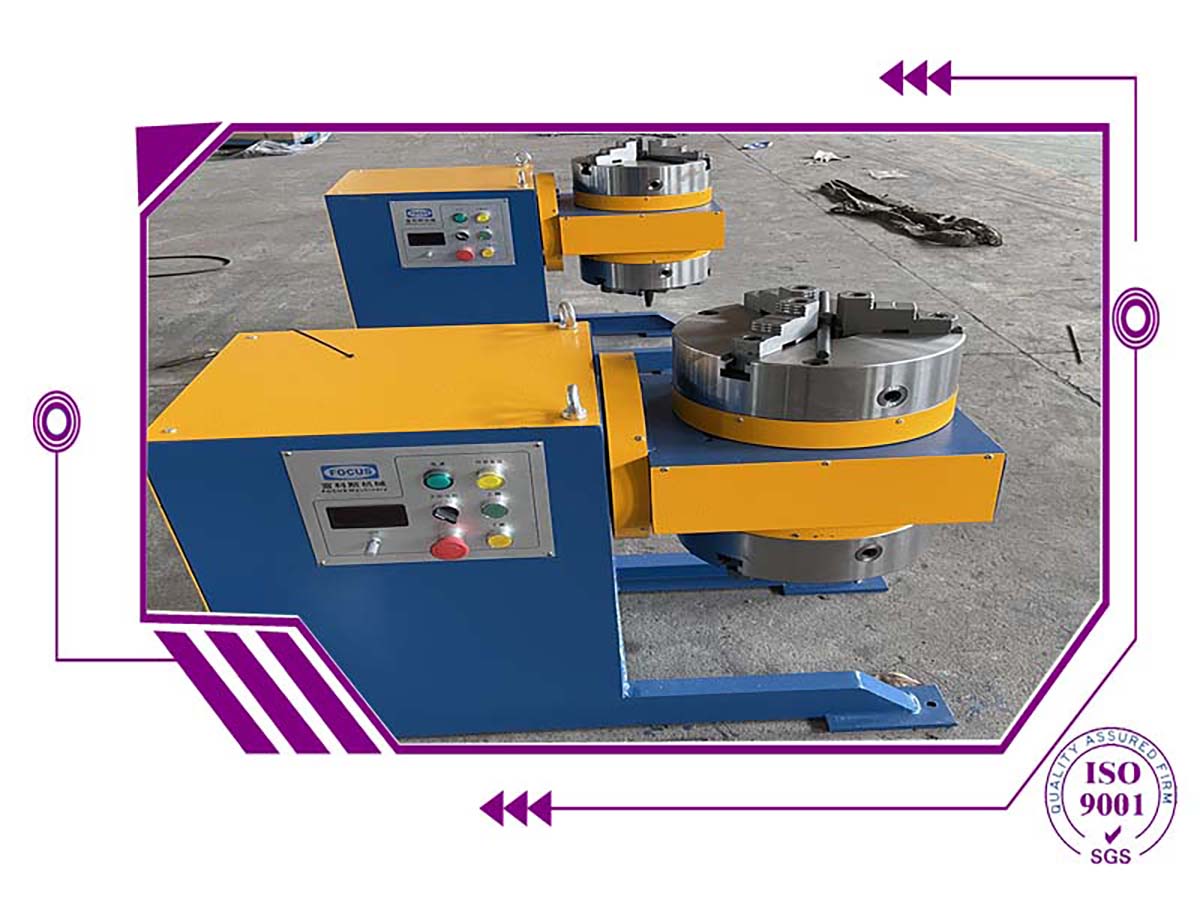

A weld positioner is a piece of equipment used in welding processes to manipulate and position the workpiece for optimal welding results. It is designed to hold and rotate the workpiece, allowing the welder to access all angles and sides of the joint with ease. Weld positioners are commonly used in industries such as manufacturing, construction, and metal fabrication to improve efficiency and accuracy in welding operations. This article will explore the features, benefits, and applications of weld positioners in various industries.

"Article:Weld Positioner: A Useful Tool for Welding ProjectsWeld positioners are an essential tool in the welding industry, providing a convenient and efficient way to manipulate and position workpieces during the welding process. These devices are designed to improve productivity, reduce operator fatigue, and ensure high-quality welds. In this article, we will explore the benefits and applications of weld positioners, as well as the different types available in the market.Neutral tagline:Exploring the benefits and applications of weld positioners in the welding industry."

A weld positioner is a piece of equipment used in welding processes to manipulate and position the workpiece for optimal welding results. It is designed to hold and rotate the workpiece, allowing the welder to access all angles and sides of the joint with ease. Weld positioners are commonly used in industries such as manufacturing, construction, and metal fabrication to improve efficiency and accuracy in welding operations. This article will explore the features, benefits, and applications of weld positioners in various industries.

What are the main benefits of using a weld positioner in the welding process?

When it comes to welding, using a weld positioner can greatly improve the efficiency and quality of the welding process. A weld positioner is a device that allows the welder to rotate and position the workpiece, making it easier to access all sides of the joint. There are several main benefits of using a weld positioner in the welding process:

- Improved Weld Quality: One of the main benefits of using a weld positioner is that it allows for better access to the joint, resulting in improved weld quality. By being able to rotate and position the workpiece, the welder can reach all areas of the joint more easily, leading to a more consistent and uniform weld.

- Increased Productivity: Using a weld positioner can also increase productivity in the welding process. With the ability to rotate and position the workpiece, the welder can complete the job more quickly and efficiently, reducing the overall time it takes to complete a weld.

- Reduced Welder Fatigue: Welding can be a physically demanding job, especially when working on large or heavy workpieces. A weld positioner can help reduce welder fatigue by allowing the workpiece to be positioned at a comfortable working height and angle, reducing strain on the welder's body.

- Enhanced Safety: Using a weld positioner can also improve safety in the welding process. By being able to rotate and position the workpiece, the welder can avoid awkward and potentially dangerous positions, reducing the risk of injury.

Overall, using a weld positioner in the welding process offers several benefits, including improved weld quality, increased productivity, reduced welder fatigue, and enhanced safety.

How does a weld positioner improve the efficiency and accuracy of welding operations?

Welding is a crucial process in various industries, and the efficiency and accuracy of welding operations are essential for ensuring the quality of the final product. One tool that can significantly improve the efficiency and accuracy of welding operations is a weld positioner.

A weld positioner is a device that is used to hold and rotate the workpiece during welding. It allows the welder to easily position the workpiece at the optimal angle for welding, reducing the need for awkward body positions and minimizing the risk of human error. Here are some ways in which a weld positioner can improve welding operations:

- Improved access: A weld positioner allows the workpiece to be rotated and tilted, providing better access to all sides of the joint. This makes it easier for the welder to reach difficult-to-access areas, resulting in more consistent and higher quality welds.

- Increased productivity: By eliminating the need for manual repositioning of the workpiece, a weld positioner can significantly reduce the time it takes to complete a welding job. This increased productivity can lead to cost savings and faster project completion.

- Enhanced safety: Welding in awkward positions can lead to fatigue and increased risk of injury. A weld positioner helps to reduce the physical strain on the welder, making the welding process safer and more comfortable.

- Greater accuracy: With the ability to precisely position the workpiece, a weld positioner allows for more accurate and consistent welds. This can result in improved weld quality and reduced rework.

In conclusion, a weld positioner is a valuable tool for improving the efficiency and accuracy of welding operations. By providing better access, increasing productivity, enhancing safety, and ensuring greater accuracy, a weld positioner can help to optimize the welding process and ultimately lead to better quality products.

In conclusion, weld positioners are valuable tools in the welding industry, providing a means to manipulate and position workpieces for optimal welding efficiency and quality. They offer a range of benefits, including increased productivity, improved weld quality, and reduced operator fatigue. While there are various types and sizes of positioners available, each serves the common purpose of enhancing the welding process. As technology continues to advance, we can expect further developments in weld positioner capabilities, further improving the welding industry as a whole.