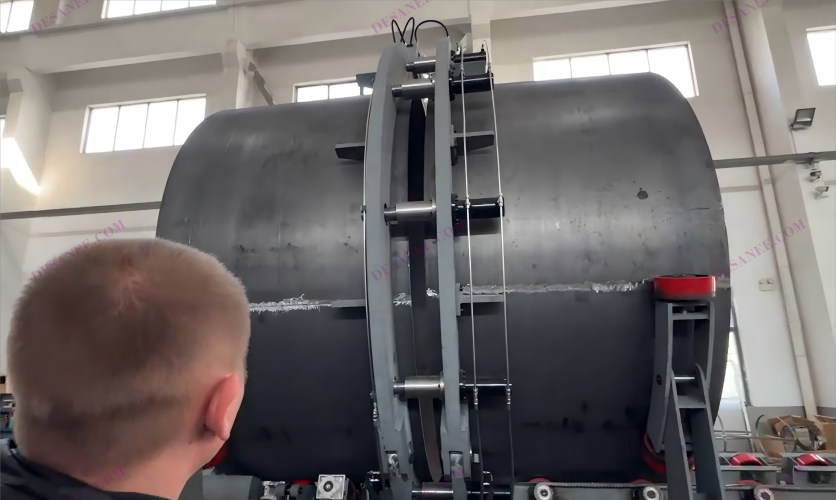

Explosion proof rotator SAR80 is a kind of our advanced welding equipment , which is be researched and manufactured absorbing domestic and international advanced equipment .it is mainly used for pipe, containers, boilers, pressure vessels, oil tank and other cylinder’s assembling, burnishing and welding, can use together with column and boom and SAW system to realize inside and outside girth and longitudinal welding. Its series includes self aligning rotators (SAR), and conventional rotators (WR). Other customize have trolley tilting anti drift rotator; Accordingly this device has advantages of compact structure, small cubage, beautiful shape, lightweight, convenient operating and so on. The machine can assort all kinds of auto welding or manual welding, improving welding quality, lessening welding labor and improve productivity.

We can provide solutions to unique Explosion proof rotator according to the customer’s requirement

Notes:

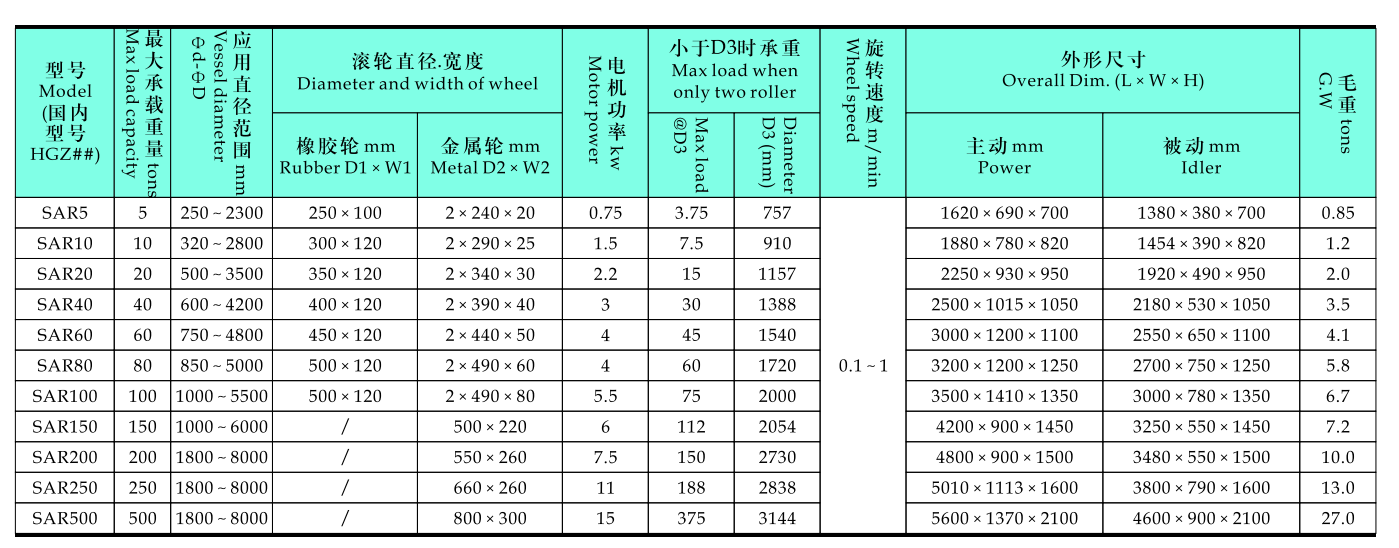

- a) Explosion proof rotator Variable rotation speed from 100 to 1000 mm/min: included

- b) Wheels padded with heavy duty rubber: Included on models SAR 100 and smaller

- c) Remote control box with 6-12 m span: included, and allows adjustment of rotating speed –digital display in mm/min-,forward and reverse rotation, and stop

- d) Auto adjusted tilt angle of roller bed as per diameter of work piece

- e) Shot blasted frame at SA 2 ½: included

- f) Variable Frequency Driver (VFD) made by Teco or other brand

- g) Custom built welding rotators: available

- h) CE mark only under customer request

- i) The information contained in this brochure is intended to be accurate. However the manufacturer retain the rights to make changes in design which may not be include

Standard package includes

One power unit with control box

One idler unit

Operation manual

One year warranty

Explosion proof rotator SAR80 (welding rorator)is used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

Optional:

+Turning rolls mounted over manual or motorized bogies

+ Synchronized operation of multi number of power rotators

+ Pu roller instead of rubber roller