Welding rotators are essential pieces of equipment used in the welding industry to assist in the manipulation and positioning of cylindrical workpieces. These rotators are designed to rotate and support heavy workpieces, allowing for precise and efficient welding operations. With various models and sizes available, welding rotators are utilized in a wide range of industries, including shipbuilding, construction, and manufacturing. This article will explore the functions, benefits, and applications of welding rotators, providing a comprehensive overview of their role in the welding process.

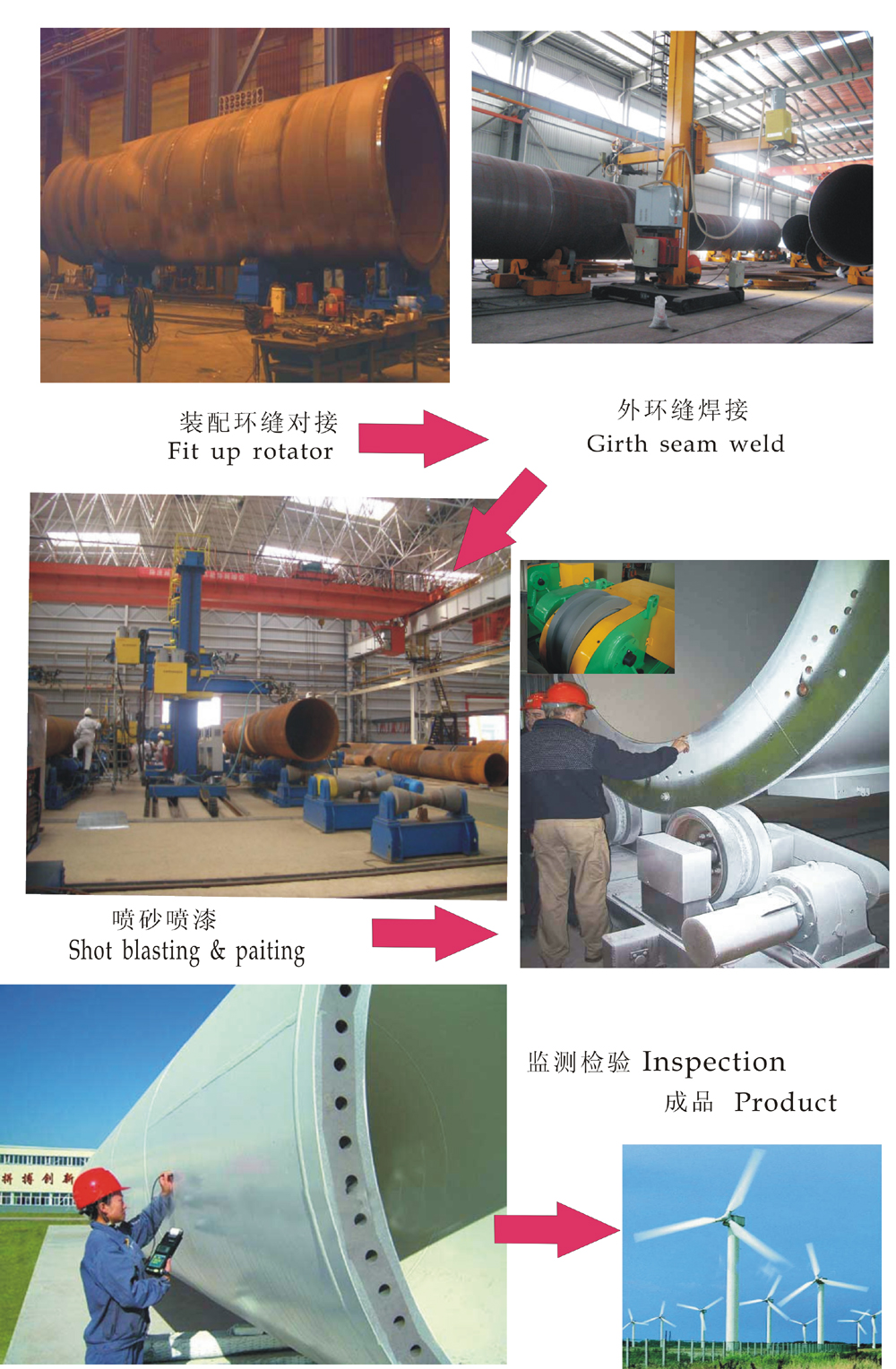

Wind power is publicly acknowledged as clean and recycling resource around the world, popularizing among countries. DESAN is one of the earliest famous suppliers specialized in tower butt welding for wind tower ,all part are fitup rotator ,internationally, and now DESAN has become the main supplier in complete wind tower line field

Our company:

---- Based on the integration of domestic and foreign wind tower welding production line successful experience and mature technology of the whole plant production process;

---- Based on the deep understanding and cognition of each process link of wind tower manufacturing plant;

---- Based on the successful cases of providing various production lines and equipment for many domestic and foreign wind tower manufacturers;

We can provide you with:

1, wind power tower welding production line of the whole plant process design and planning services;

2, wind power tower welding production line of the whole plant equipment manufacturing, installation and commissioning training services;

3, wind power tower welding production line of the whole plant equipment long-term perfect after-sales service;

Wind tower butt welding and Fit up rotator is used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

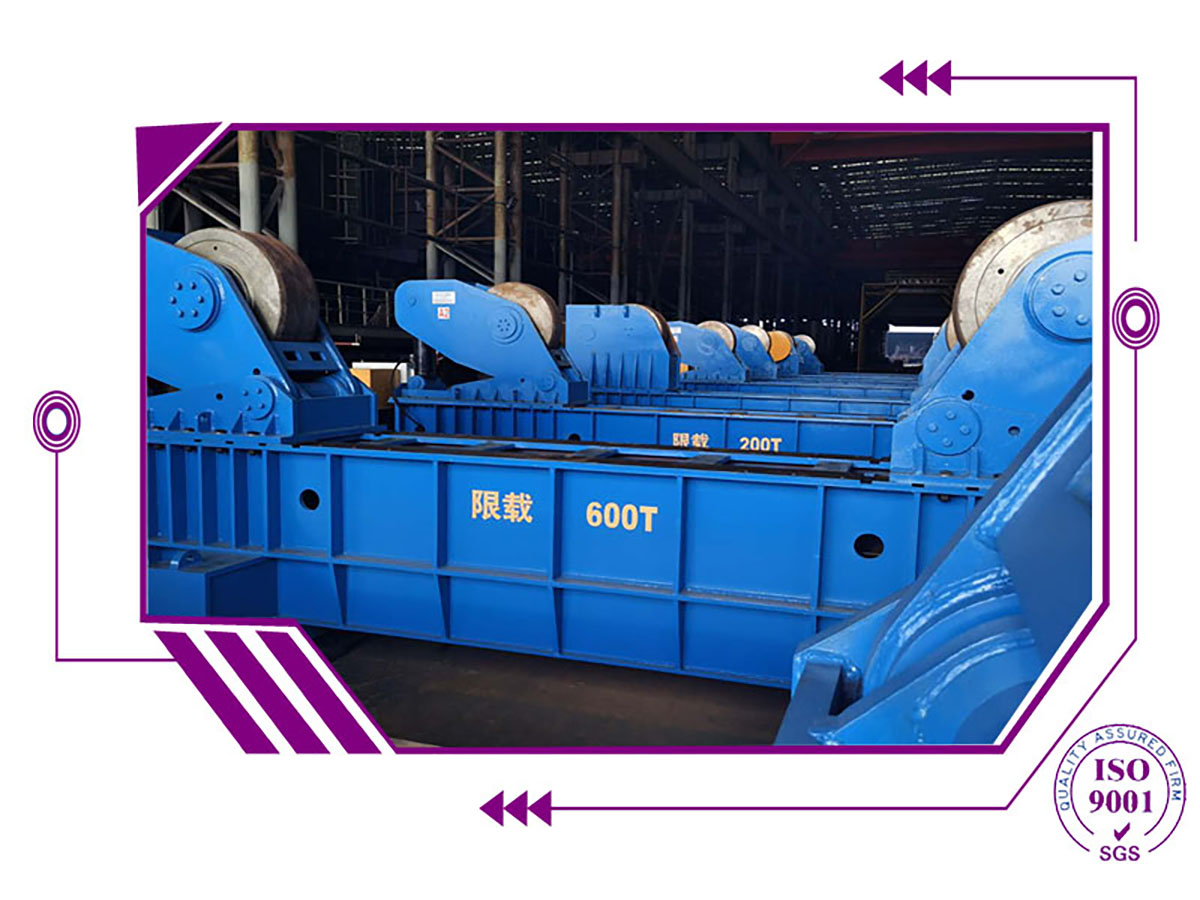

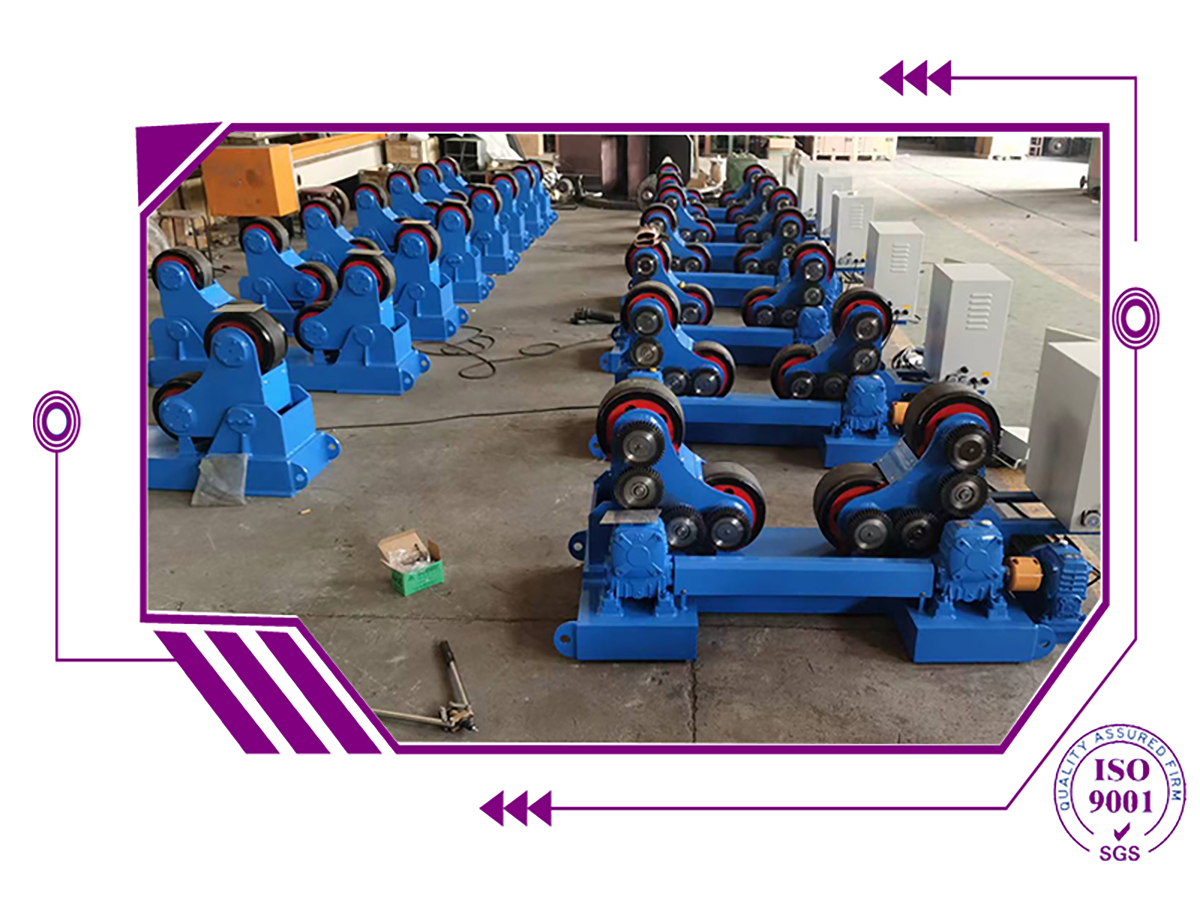

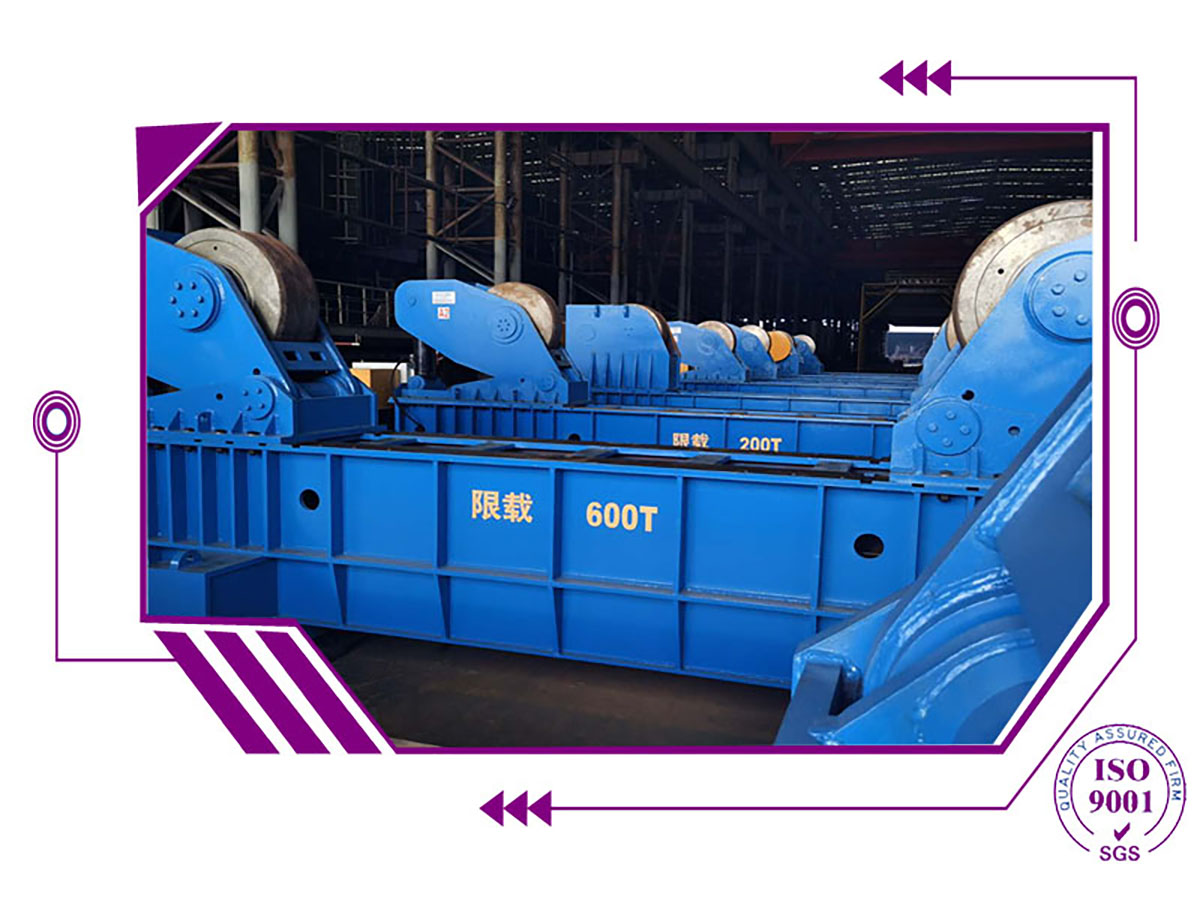

Wind Fitup Rotator WR600F is a kind of our advanced welding equipment , which is be researched and manufactured absorbing domestic and international advanced equipment .Wind Fitup Rotator WR600F is mainly used for pipe, containers, boilers, pressure vessels, oil tank and other cylinder’s assembling, burnishing and welding, can use together with column and boom and SAW system to realize inside and outside girth and longitudinal welding. Its series includes self aligning rotators (SAR), and conventional rotators (WR). Other customize have trolley tilting anti drift rotator; Accordingly this device has advantages of compact structure, small cubage, beautiful shape, lightweight, convenient operating and so on. The machine can assort all kinds of auto welding or manual welding, improving welding quality, lessening welding labor and improve productivity.

We can provide solutions to unique welding rotator according to the customer’s requirement

Wind Fitup Rotator WR600F (welding rorator) is used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

Notes:

- a) Variable rotation speed from 100 to 1000 mm/min: included

- b) Wheels padded with black PU roller : Included on models WR- 100 and smaller

- c) Remote control box with 6-12 m span: included, and allows adjustment of rotating speed –digital display in mm/min-,forward and reverse rotation, and stop

- d) Custom built --LD stands for large diameter vessels

- e) Shot blasted frame at SA 2 ½: included

- f) Variable Frequency Driver (VFD) made by Teco other brand

- g) Custom built welding rotators available

- h) CE mark only under customer request

- i) The information contained in this brochure is intended to be accurate. However the manufacturer retain the rights to make changes in design which may not be include

Fitup Rotator is used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

Optional:

+Turning rolls mounted over manual or motorized bogies

+Synchronized operation of multi number of power rotators

+anti drifting function including one side uplift and double uplift.

+ Pu roller instead of rubber roller( from 2020yr ,start USE PU)

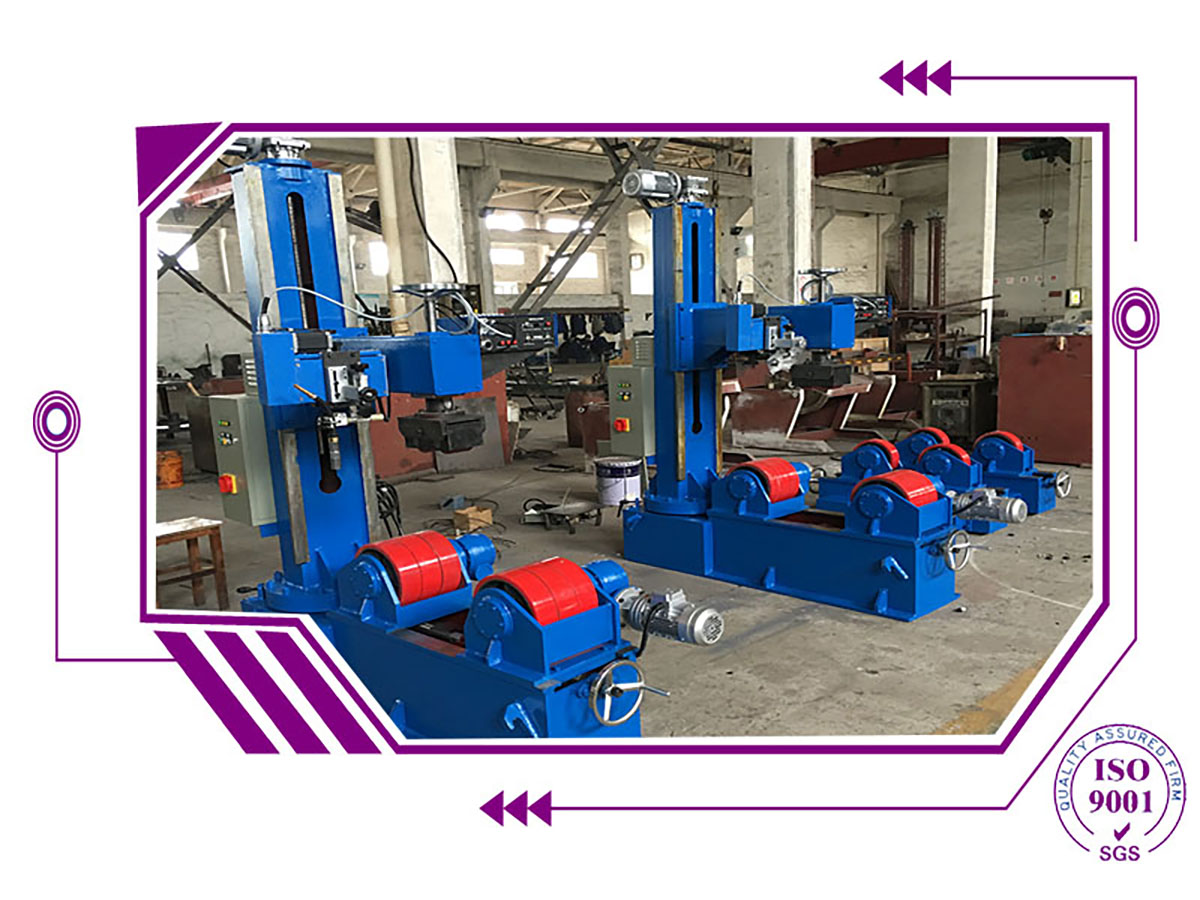

Small PIPE Rotator PR1A is a kind of our advanced welding equipment , which is be researched and manufactured absorbing domestic and international advanced equipment .Small PIPE Rotator PR1A is mainly used for pipe, containers, boilers, pressure vessels, oil tank and other cylinder’s assembling, burnishing and welding, can use together with column and boom and SAW system to realize inside and outside girth and longitudinal welding. Its series includes self aligning rotators (SAR), and conventional rotators (WR). Other customize have trolley tilting anti drift rotator; Accordingly this device has advantages of compact structure, small cubage, beautiful shape, lightweight, convenient operating and so on. The machine can assort all kinds of auto welding or manual welding, improving welding quality, lessening welding labor and improve productivity.

We can provide solutions to unique welding rotator according to the customer’s requirement

Small PIPE Rotator PR1A is(welding rorator) used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

Notes:

a) Variable rotation speed from 100 to 1000 mm/min: included

b) Wheels padded with black PU roller : Included on models WR- 100 and smaller

c) Remote control box with 6-12 m span: included, and allows adjustment of rotating speed –digital display in mm/min-,forward and reverse rotation, and stop

d) Custom built --LD stands for large diameter vessels

e) Shot blasted frame at SA 2 ½: included

f) Variable Frequency Driver (VFD) made by Teco other brand

g) Custom built welding rotators available

h) CE mark only under customer request

i) The information contained in this brochure is intended to be accurate. However the manufacturer retain the rights to make changes in design which may not be include

Optional:

+Turning rolls mounted over manual or motorized bogies

+Synchronized operation of multi number of power rotators

+anti drifting function including one side uplift and double uplift.

+ Pu roller instead of rubber roller( from 2020yr ,start USE PU)

Pipe rotator is specially designed and manufactured for the purpose of meeting the requirements of enhancing productivity, increasing the extent of automatic, reducing welder’s working intensity and adapting to piping workshop prefabrication. The welding head will be relatively fixed, while the piping spool piece revolving at a specific rate, and the high efficient and low cost shielded welding or SAW process is adopted, so it has the features of easy-operation, reliable-performance and wide-application field.

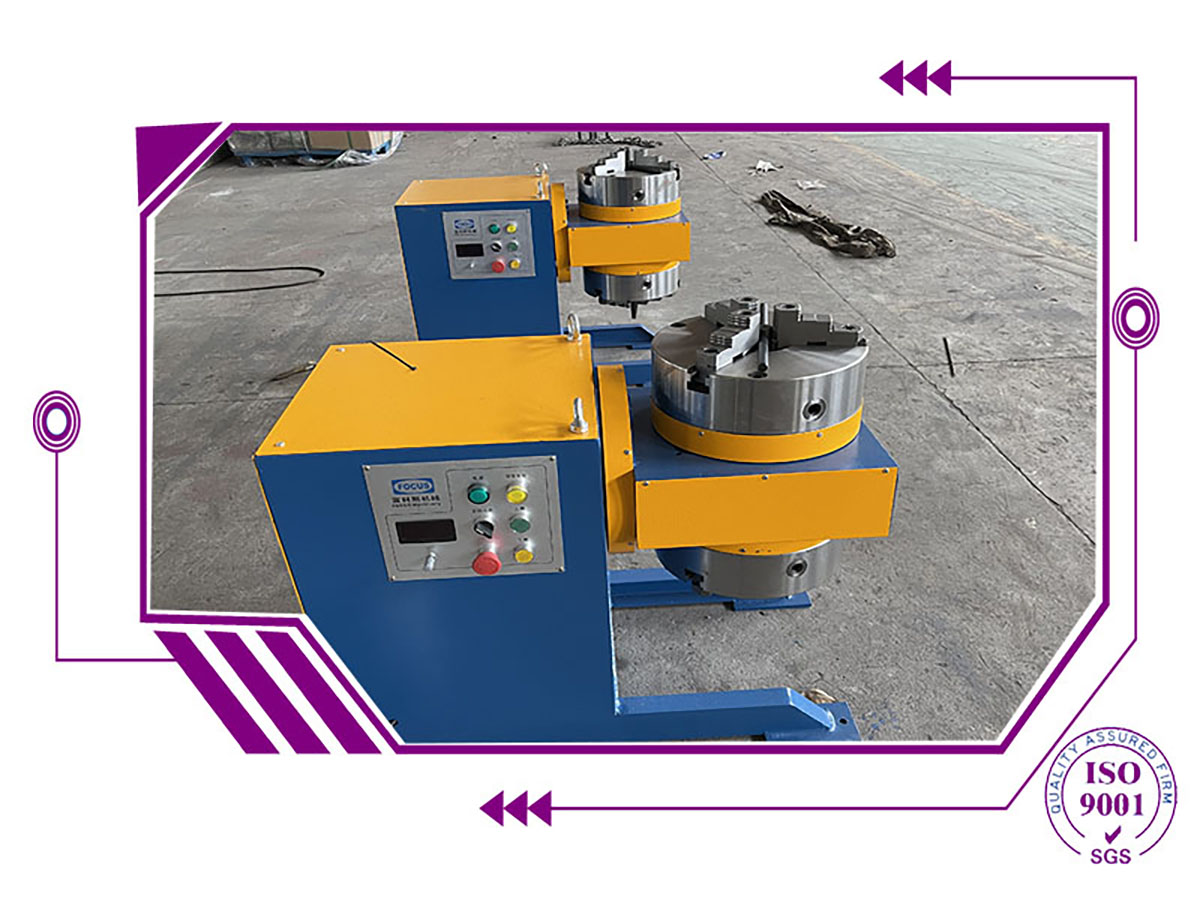

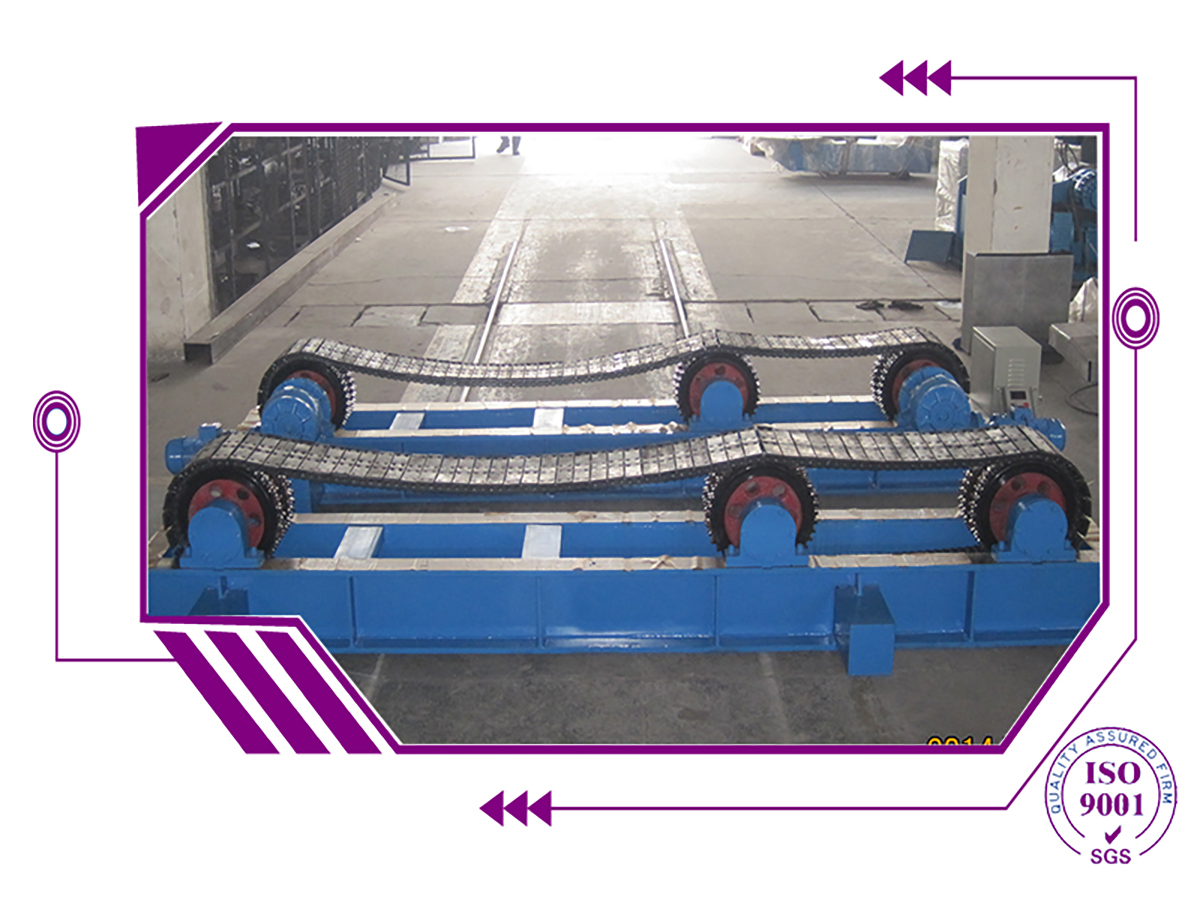

Chain Rotator CWR20 is a kind of our advanced welding equipment , which is be researched and manufactured absorbing domestic and international advanced equipment .Chain Rotator CWR20 is mainly used for pipe, containers, boilers, pressure vessels, oil tank and other cylinder’s assembling, burnishing and welding, can use together with column and boom and SAW system to realize inside and outside girth and longitudinal welding. Its series includes self aligning rotators (SAR), and conventional rotators (WR). Other customize have trolley tilting anti drift rotator; Accordingly this device has advantages of compact structure, small cubage, beautiful shape, lightweight, convenient operating and so on. The machine can assort all kinds of auto welding or manual welding, improving welding quality, lessening welding labor and improve productivity.

We can provide solutions to unique welding rotator according to the customer’s requirement.E.G chian type also call Chain rotator CWR20 for thin wall tank.

Chain Rotator CWR20 (welding rorator) is used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

Notes:

- a) Variable rotation speed from 100 to 1000 mm/min: included

- b) Wheels padded with black PU roller : Included on models WR- 100 and smaller

- c) Remote control box with 6-12 m span: included, and allows adjustment of rotating speed –digital display in mm/min-,forward and reverse rotation, and stop

- d) Custom built --LD stands for large diameter vessels

- e) Shot blasted frame at SA 2 ½: included

- f) Variable Frequency Driver (VFD) made by Teco other brand

- g) Custom built welding rotators available

- h) CE mark only under customer request

- i) The information contained in this brochure is intended to be accurate. However the manufacturer retain the rights to make changes in design which may not be include

Optional:

+Turning rolls mounted over manual or motorized bogies

+Synchronized operation of multi number of power rotators

+anti drifting function including one side uplift and double uplift.

+ Pu roller instead of rubber roller( from 2020yr ,start USE PU)

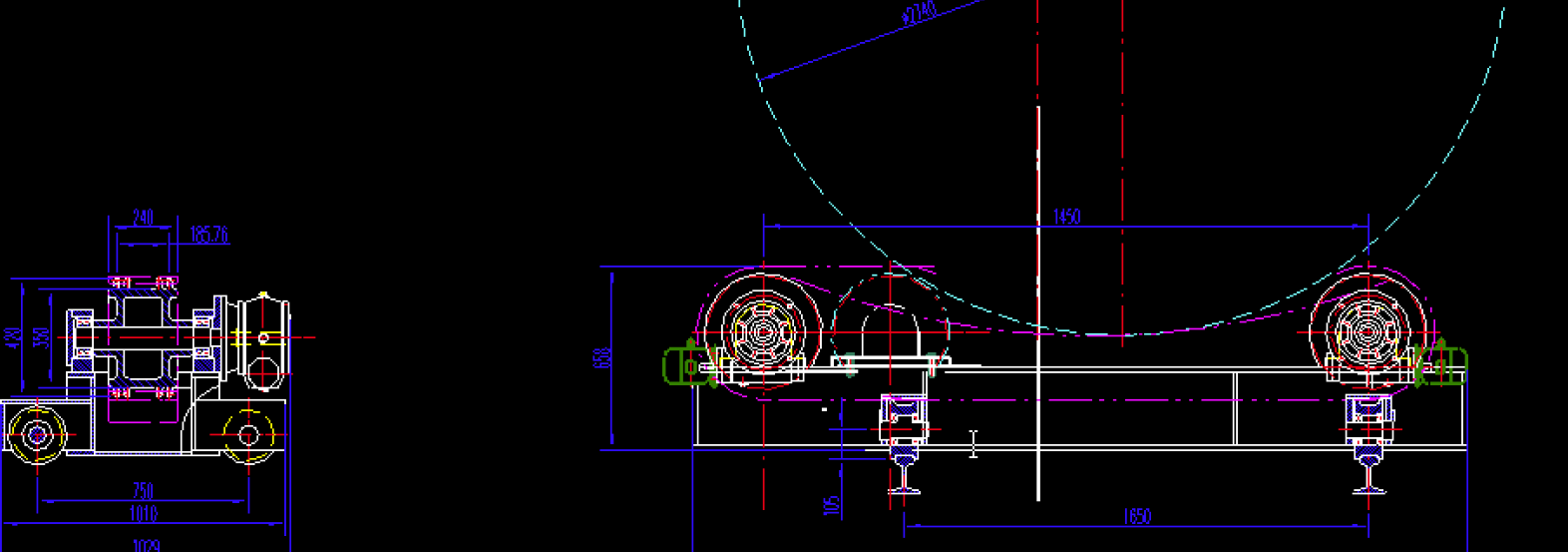

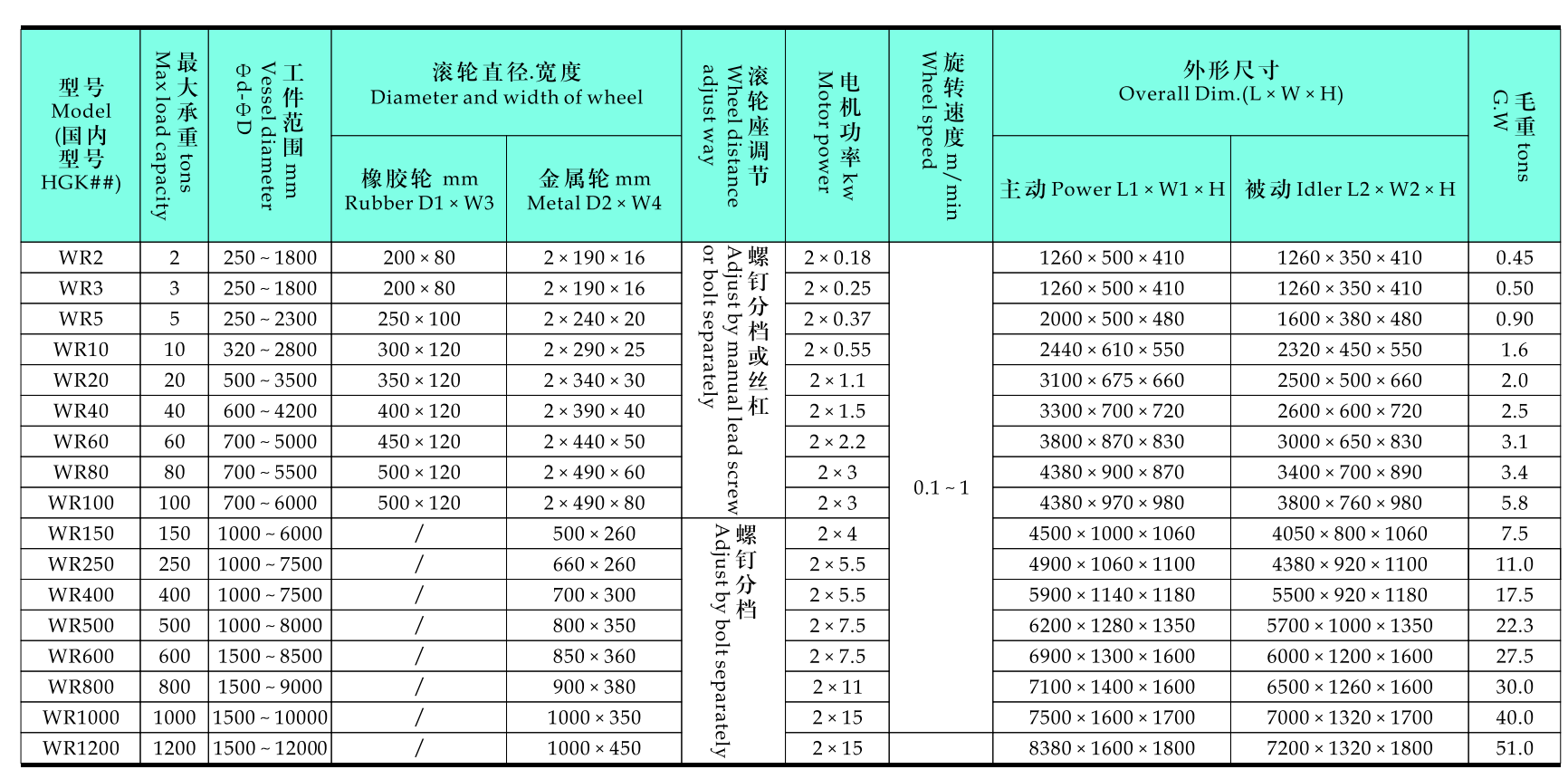

TECHNICAL PARAMETERS

Chain rotator 20

1: Power rotator : 20t rotating capacity

10 t loading capacity

2: Idler rotator : 10 t loading capacity

3: Idler bogies: included

4: Vessel diameter :

900mm--3050mm

5: Roller: 420x240 mm

6: Chain :cover with heavy duty rubber

7: Input power : 480 V 60Hz 3P

8:Power of motor: 2x1.5kw