Keyhole TIG welding not only has advantages in speed over double gun composite P+T welding!

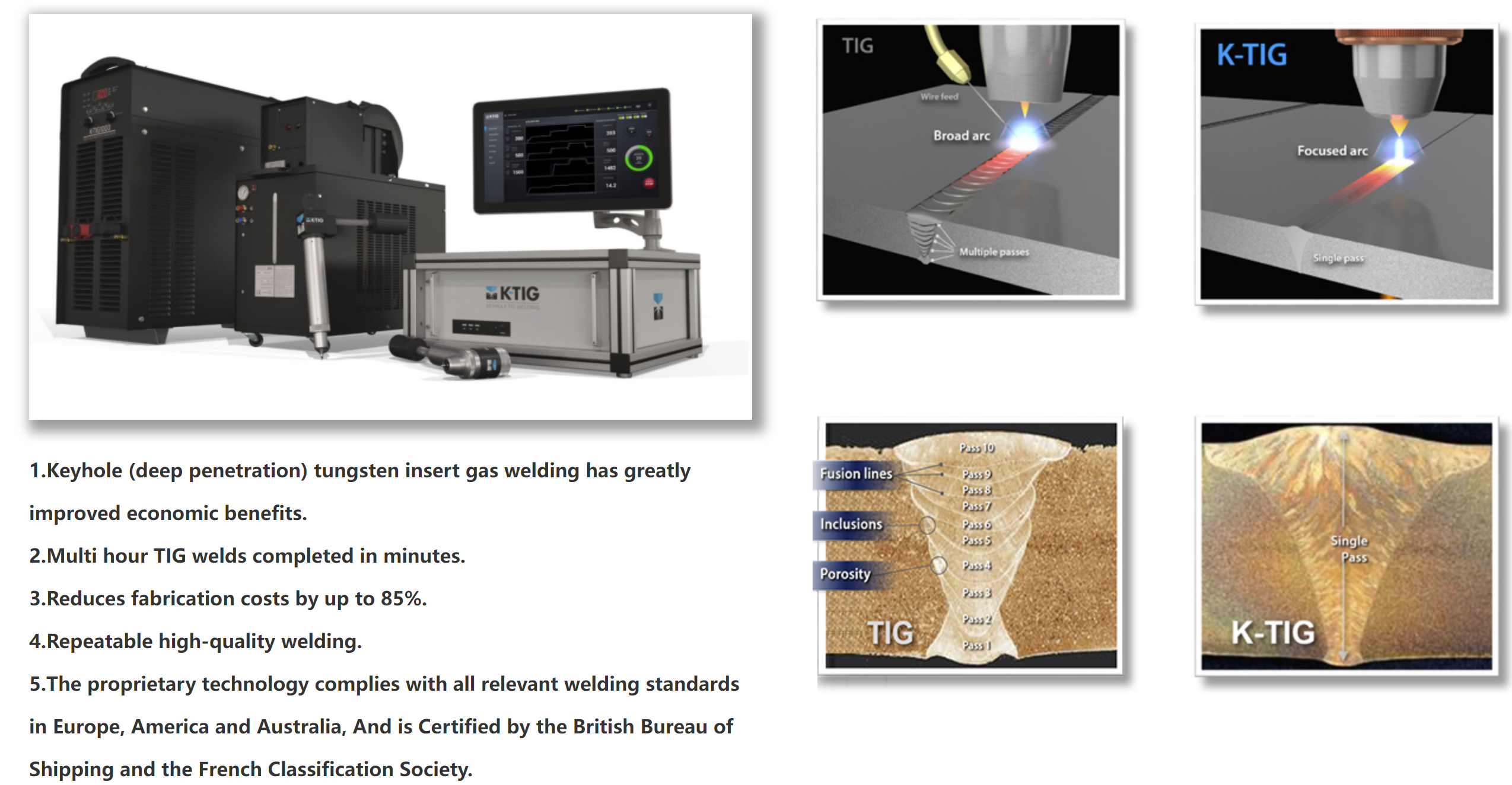

1 Concept;

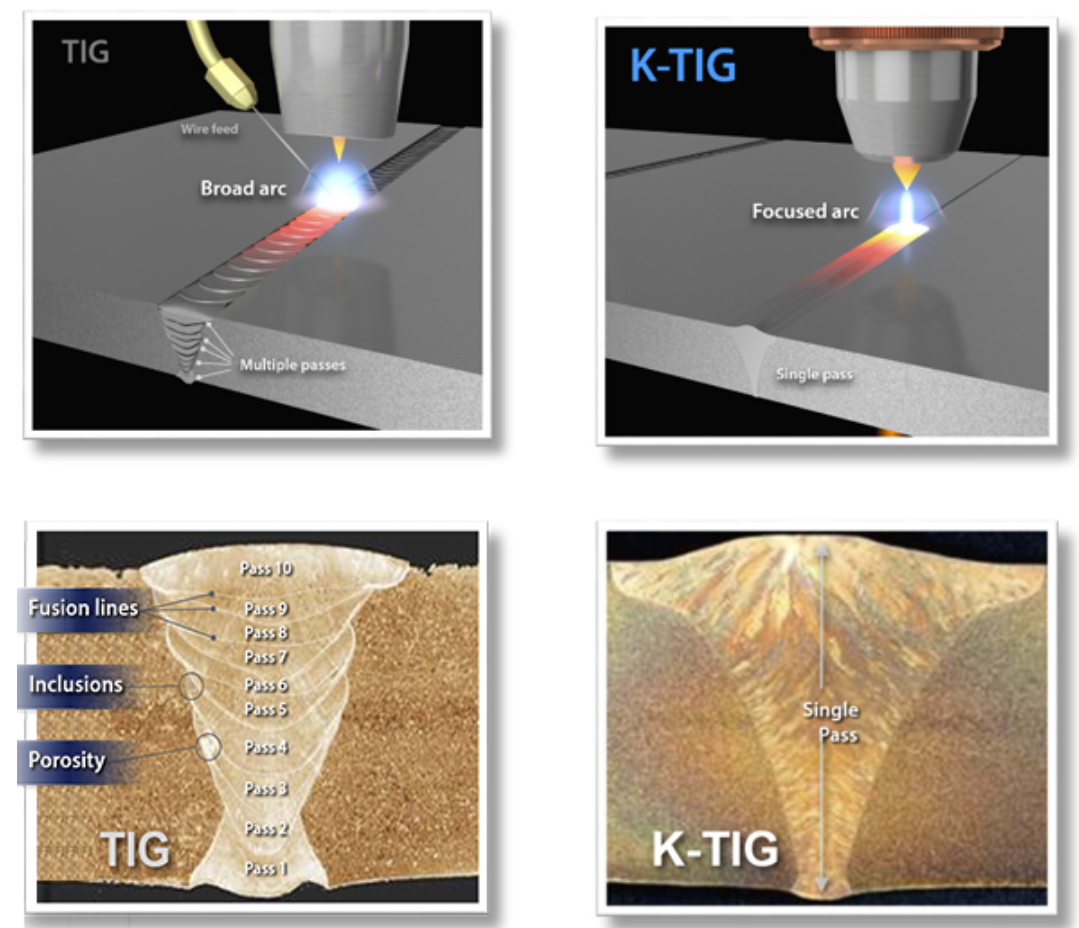

1.1 K-TIG "Keyhole"TIG (keyhole or small hole) also Keyhold TIG welding, not only has the beautiful cover effect of ordinary TIG welding, but also has the characteristics of super-penetrating power of plasma welding

1.2 P+T double gun composite welding: Plasma plasma welding gun and TIG welding gun are fixed into a welding gun, to realize plasma-TIG composite welding to make full use of the advantages of plasma arc welding and TIG welding methods;

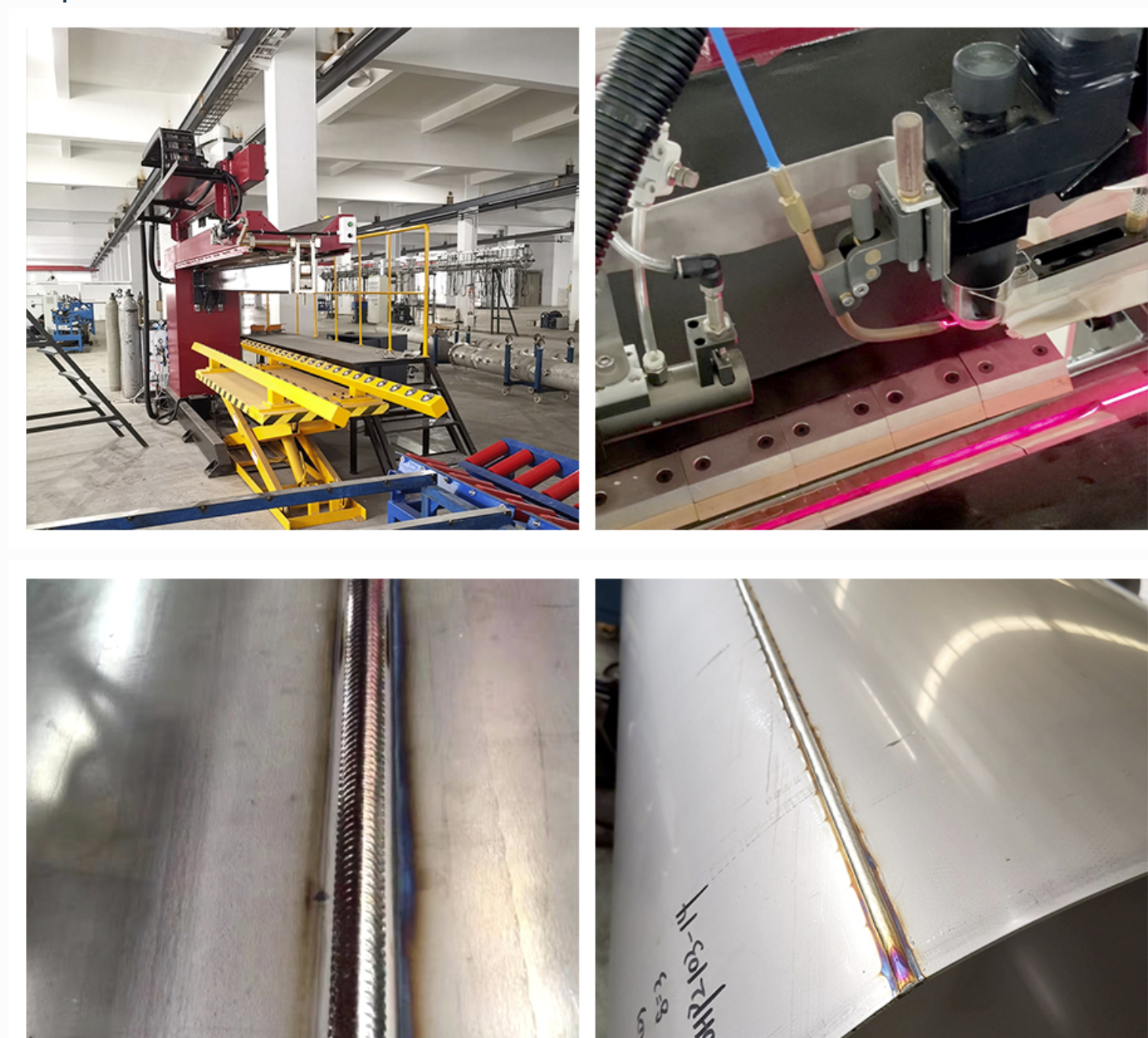

2.1 P+T composite welding

In recent years, composite welding technology has been a research hotspot in the field of welding. Compared with the common single arc welding, the composite welding technology can effectively improve the welding quality and efficiency

+ High efficiency and high quality plasma and TIG simultaneous welding process method, the use of plasma good hole penetration ability, to ensure the single-side welding two-sided forming at the same time, as far as possible to improve the welding speed, the free arc through TIG welding has a good cap capacity, and then with the appropriate amount of filling metal, to achieve the positive forming effect;

+ Double gun welding is about 1.3 times the efficiency of single gun welding;

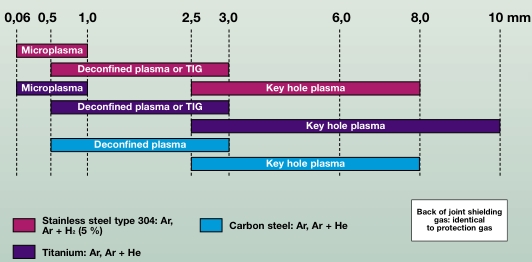

+ Suitable for long weld welding and high quality welding, mainly used in stainless steel, titanium alloy 3~10mm welding

P+T welding main process advantages:

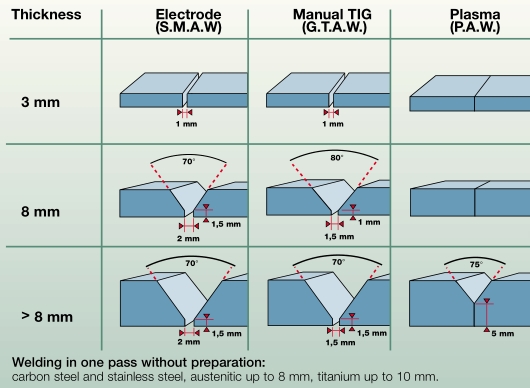

The plasma arc penetration ability is strong, the plate thickness below 8mm does not need to be bevelled, greatly reducing the preparation time before welding and reducing the amount of filler wire.

② Welding speed can be significantly improved, double gun welding at the same time, high production efficiency.

③ Can be single-sided welding double-sided forming, stable to obtain a complete regular full welding rust weld, the appearance of good forming. ④ Meet 100% X-ray inspection requirements.

⑤ arc energy concentration, welding heat affected zone is small, welding deformation is small.

The welding heat input is small, the welding heat input is small, the weld metal grain size is small compared with submerged arc welding, and the joint performance is excellent.

⑦ Welding arc has good controllability and adjustability.

⑧ can be widely used in the welding of strain strengthened vessels, and the joint performance is excellent.

⑨ The welding environment is clean, and the labor intensity is greatly reduced

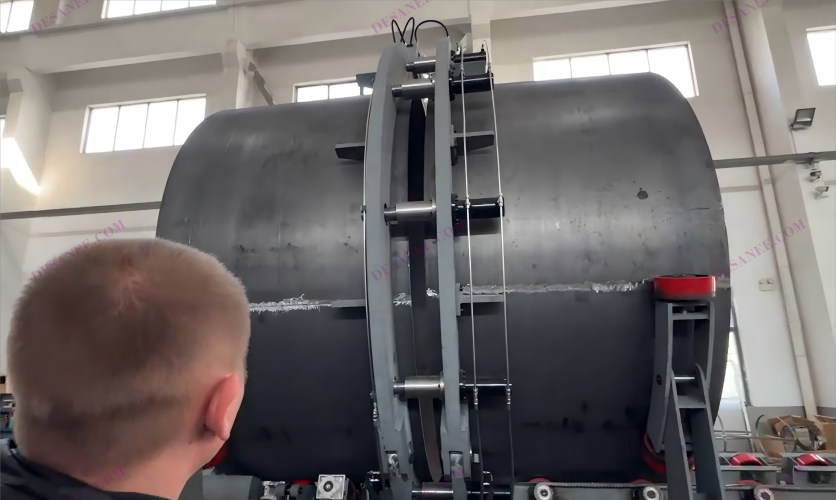

2.2 Keyhole TIG welding, K-Tig is a deep penetration welding method based on traditional Tig welding, which achieves a relative balance between the large arc pressure formed by large current and the surface tension of liquid metal in the molten pool to form small holes. The welding process is stable, the ripple is fine, the molding is beautiful, and the microstructure and mechanical properties of the weld are better than that of Tig welding, which is a real high-speed, efficient and low-cost welding method and an innovation of traditional Tig welding. The research and development of K-Tig welding can not only make full use of the advantages of Tig welding, but also effectively and greatly improve the welding depth to obtain the advantages of new Tig welding.

Keyhole TIG welding PK P+T welding

2.2.1 Application Advantages

Keyhole TIG welding does not require wire, groove opening, or professional technical operators, but can perfectly weld materials with a thickness of 3 ~ 16mm (such as titanium alloy) at a speed 10 times faster than ordinary argon tungsten arc welding technology. (Note: Less than 3% of the welding material used in conventional welding is needed to overcome the edge bite). Keyhole TIG welding-- weld is 100% parent material layer without multiple fusion lines, completely eliminating slag inclusion, porosity and common weld defects.

K-TIG efficient deep penetration arc welding non-ripple welding pool guarantees the top layer and the bottom layer of the ultra-high quality, completely eliminate the need for back root cleaning, surface polishing cleaning and grinding.

For single-pass welds, KTIG can weld the thickness of the back molding on one side

- Titanium alloy Max. 16mm

- Stainless steel 13mm

- Carbon steel 9mm

2.2.2 Technical Features

KTIG999 for Keyhole TIG welding, high efficiency deep penetration arc welding machine is a new type of high efficiency and energy saving inverter argon arc welding machine which can realize stable automatic welding. Has the following advantages:

+1, realize the automation of welding process.

+2, the operation is simple, the operator can operate independently after 2 days of training.

+3, the welding speed is fast, the speed is more than 5~10 of ordinary TIG/GTAW.

+4, the welding workpiece does not need to open the groove, can achieve single-side welding double-sided molding, beautiful weld, small deformation, the back need not clear the root.

+5, the width of the back weld is 2~3 mm, and the width of the front weld is usually about 1.5 times the thickness of the plate.

+6, the weld is formed once, and the convex weld can be realized without opening the groove or adding the welding material, and the surface can be covered synchronously if necessary.

+7, the welding fault tolerance rate is high, under a certain thickness, the gap and the wrong side of the welding workpiece can reach 2 mm.

+8, welding including carbon alloy steel, stainless steel, titanium alloy, nickel base alloy, cobalt alloy and zirconium and other materials, can ensure extraordinary welding speed and quality.

+9, Keyhole TIG welding is the first choice for the above materials in the thick plate welding, carbon alloy steel welding thickness greater than or equal to 12 mm, stainless steel and nickel-based alloys greater than or equal to 13 mm, titanium alloy, cobalt alloy and zirconium and other greater than or equal to 16 mm, more than the welding thickness of the part need to open "V" groove.

+10, Keyhole TIG welding process using argon protection.

+11, Keyhole TIG welding high welding efficiency, low energy consumption.

+12, Keyhole TIG welding low equipment maintenance cost.

现场实验:焊机K-TIG99 , /材料不锈钢/。

|

焊接厚度 thickness |

6mm |

8mm |

10mm |

|

焊接速度 weld speed |

350 |

350 |

300 |

|

电流 current |

350A |

400A |

400A |

|

气流量 aire flow |

15L/min |

20L/min |

23L/min |

|

焊缝宽度 seam width |

11mm |

13mm |

14mm |

结论:

: 速度快 30% 比P+T复合焊

Conclusion:

:Keyhole TIG weldingis 30% faster than P+T composite welding