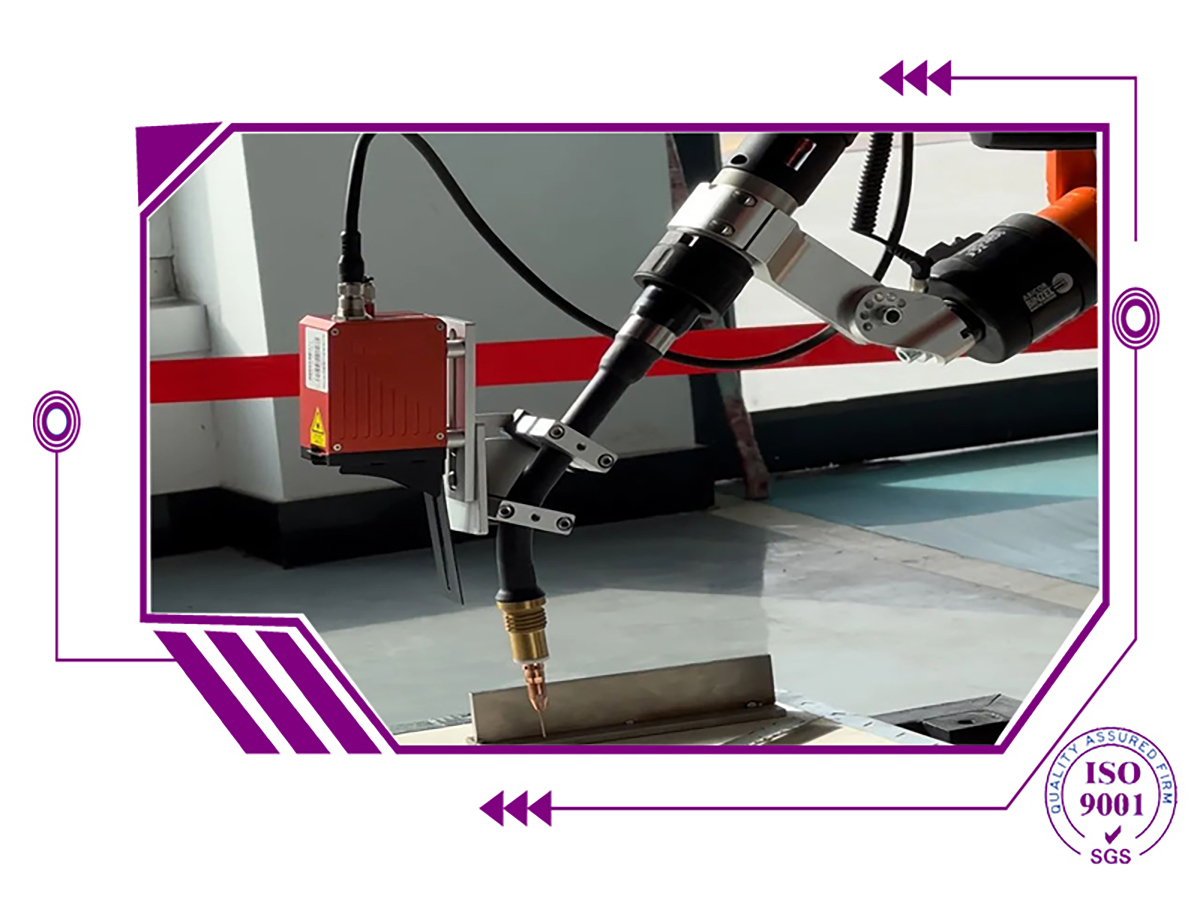

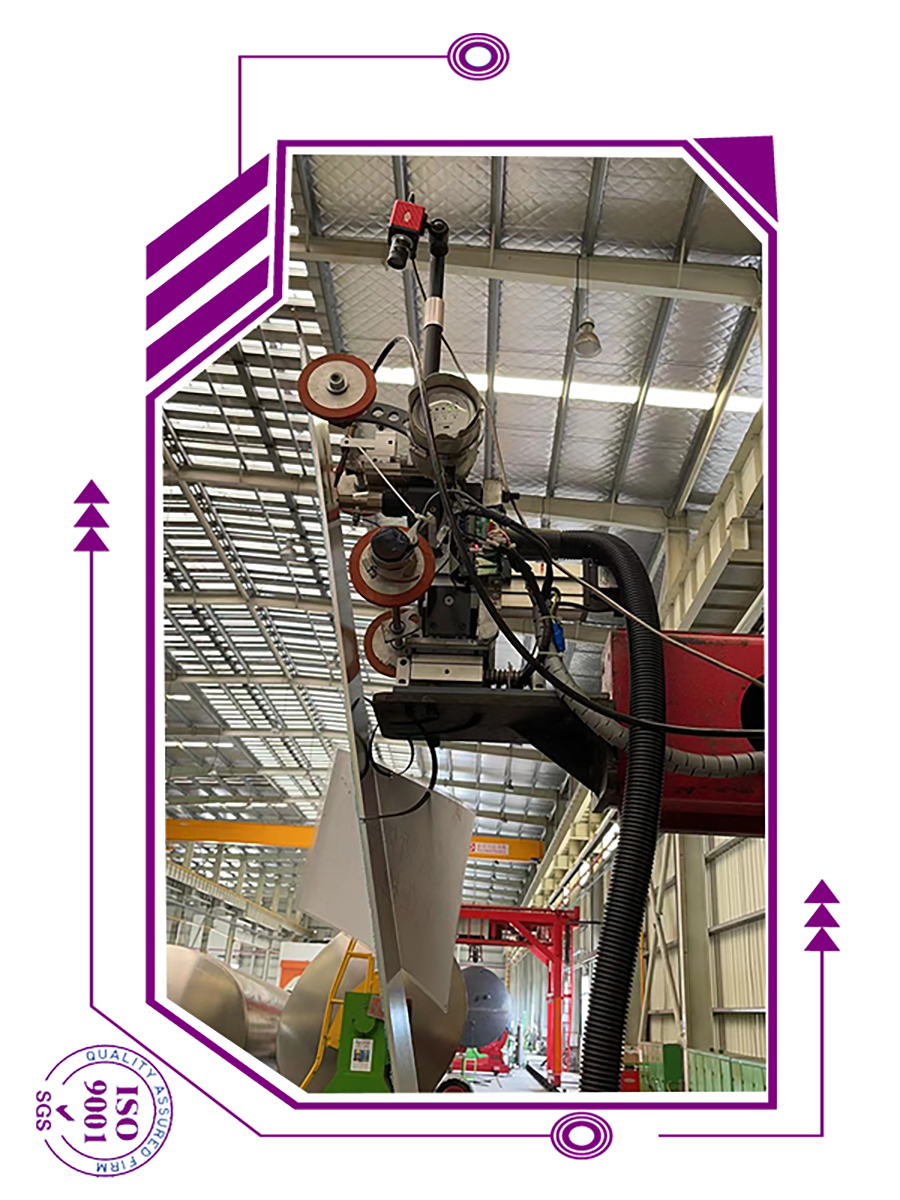

Laser Weld Tracking is one special welding auxi machine,

we can provide : 3D Laser Weld Tracking Sensors for TIG Plasma MIG Welding Monitor and Tracking Seam Laser Seam Tracking Product Used in TIG Welding Robot Argon Arc Welding

DS laser seam tracking product used in TIG welding robot with filler wire

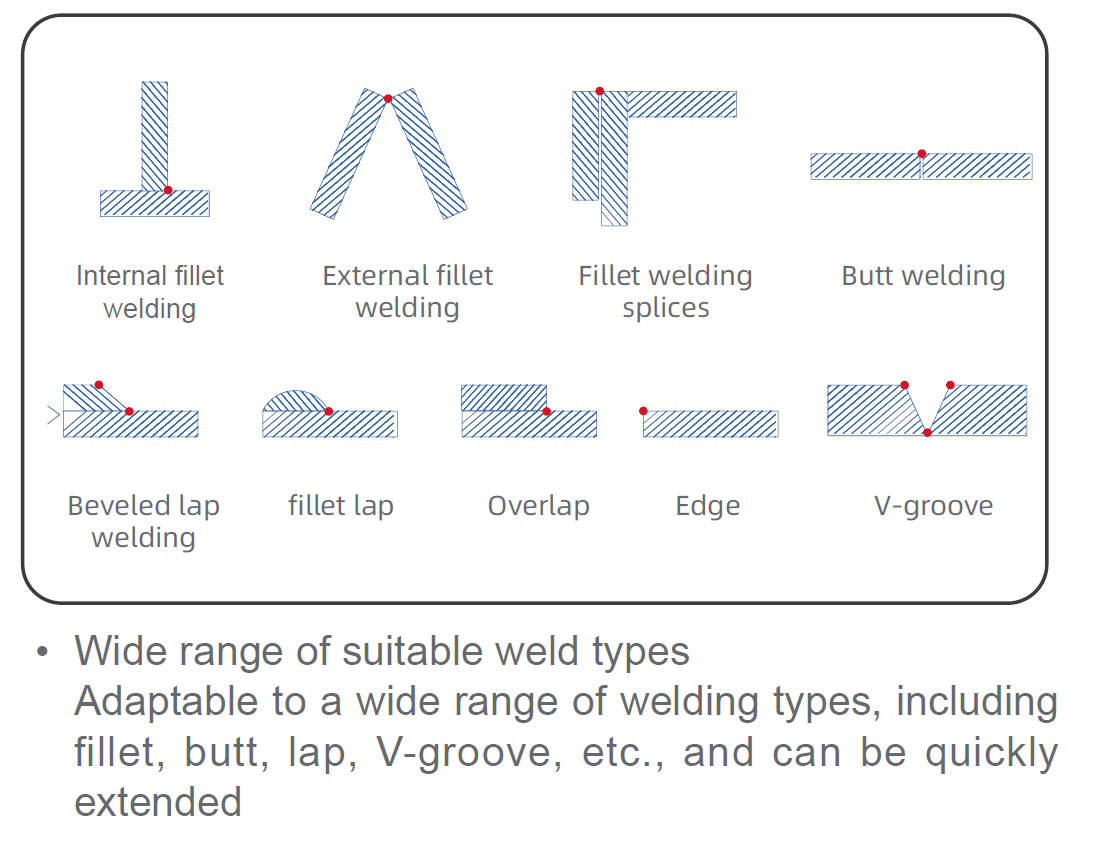

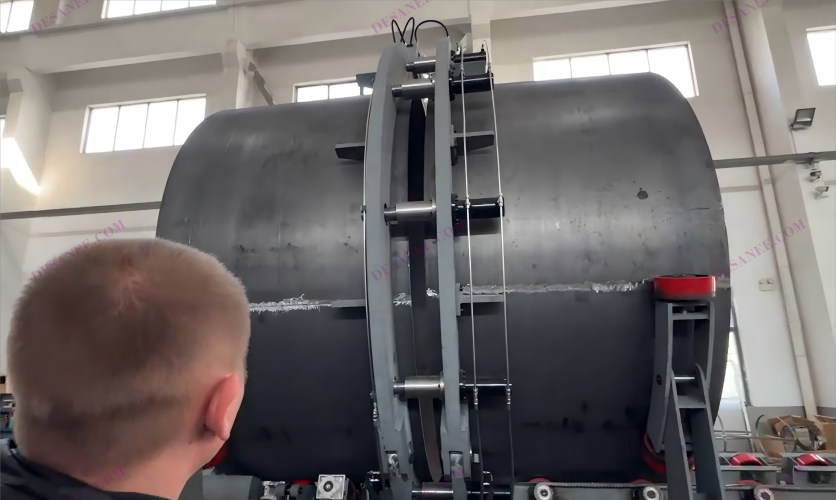

Tactile or laser-guided weld seam trackers are an automated method for accurately tracking the weld seam. Various modes allow for the tracking of many different joint designs and situations.

3D laser weld tracking sensors , DS company provides customers with 3D sensors, automatic systems exempt from programming, welding robots and completed solutions for welding specialized machine systems. Focusing on improving our own R&D and innovation capabilities, owning unique and innovative ideas in the fields of optics, electronic hardware and algorithms, and aspires to design optimal solutions for complex welding operations 3D Laser Weld Tracking Sensors for TIG Plasma MIG Welding

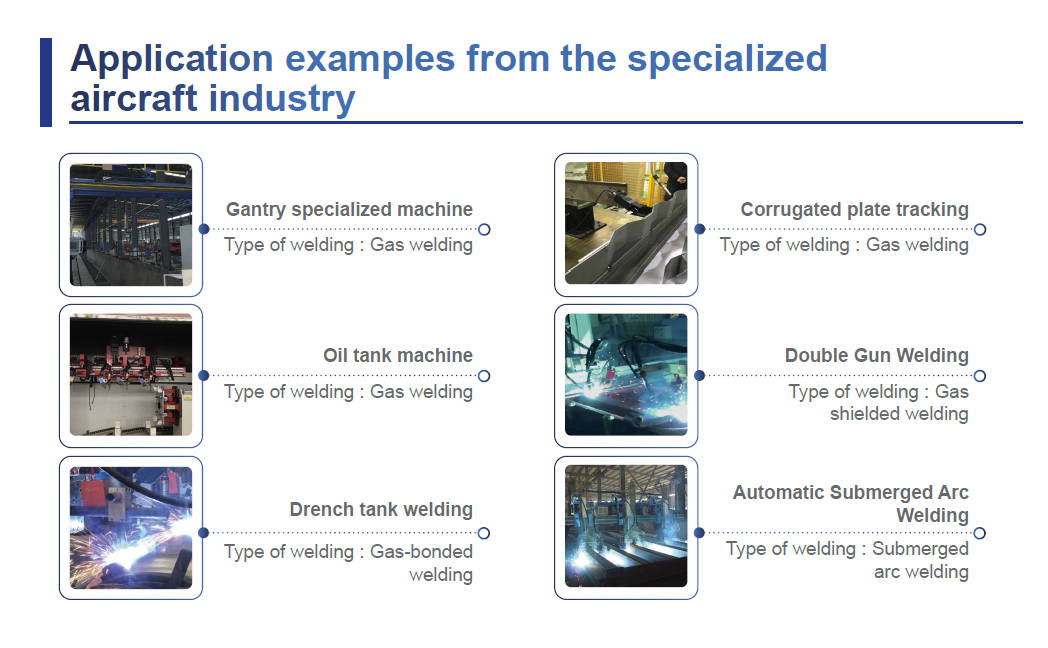

3D Laser Weld Tracking Sensors for TIG Plasma MIG Weldingis used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

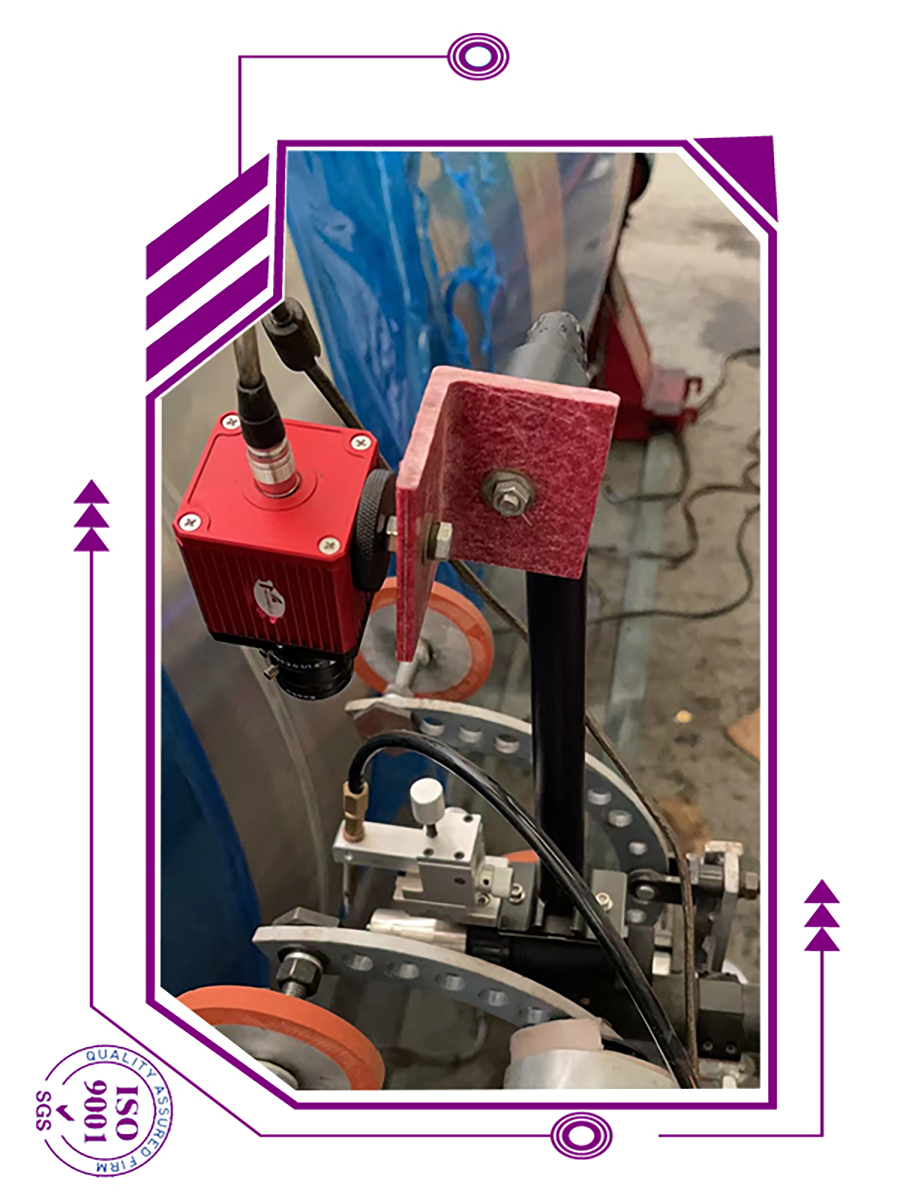

Sensor characteristics

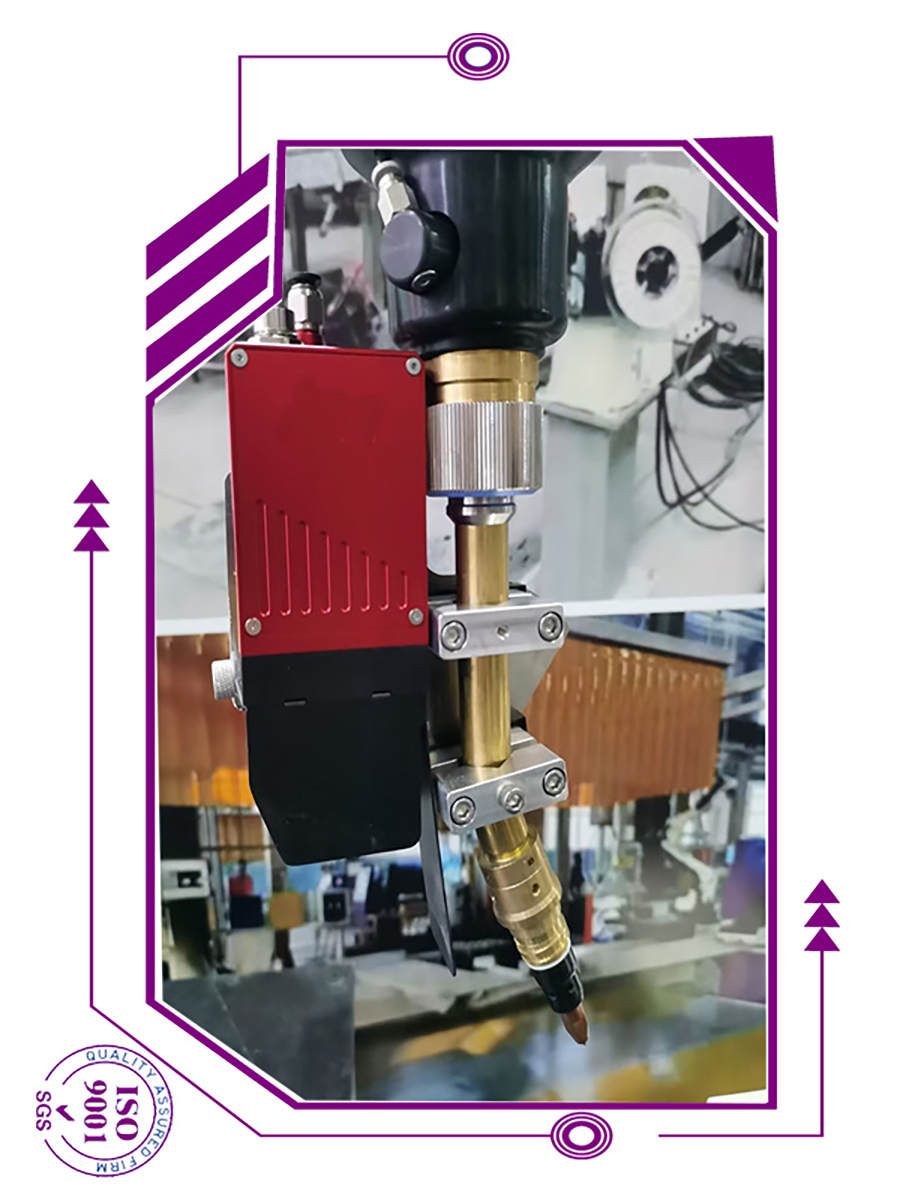

• Compact and small

Highly integrated, compact and easy to disassemble

Built-in controller, small size and low power consumption

• Well-protected design

Reliable internal structure design, suitable for complex and harsh industrial production environments

• Strong real-time tracking

Highly efficient image detection algorithm, high speed image processing speed; unique tracking and calibration

algorithm to achieve real-time tracking

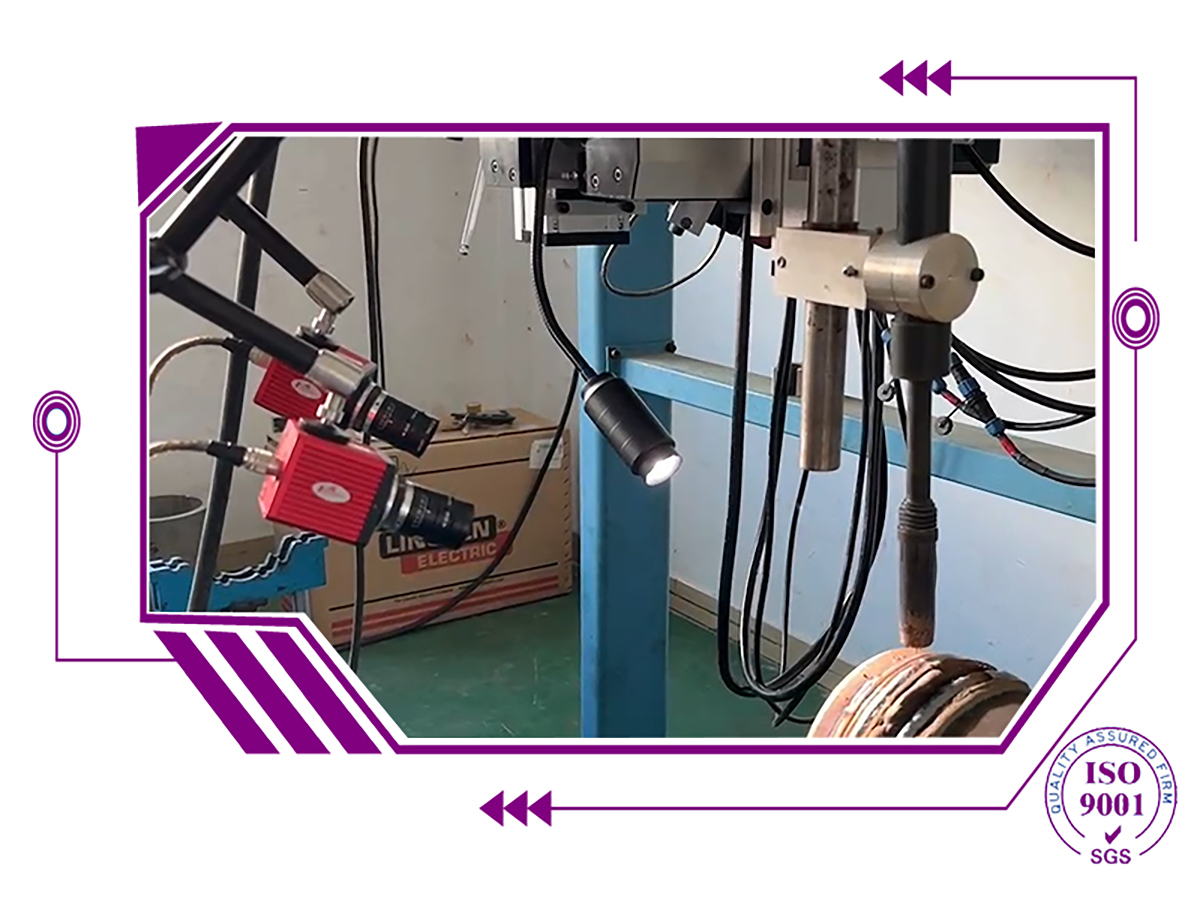

• Strong anti-interference

Built-in air cooling / air knife system; professional electrical protection design can adapt to various high frequency

electromagnetic and electrostatic industrial production environmen

• Flexible and versatile

Plug and Play anytime

Full weld support

Customised detection algorithms for non-standard welds

Communication protocols for more than 40 brands of robots

Different resolutions apply to both laser welding and MIG welding

• Simple operation

Full Chinese software interface, with a flowing parameter setting process and detailed instruction menus, even

non-experts can quickly get started

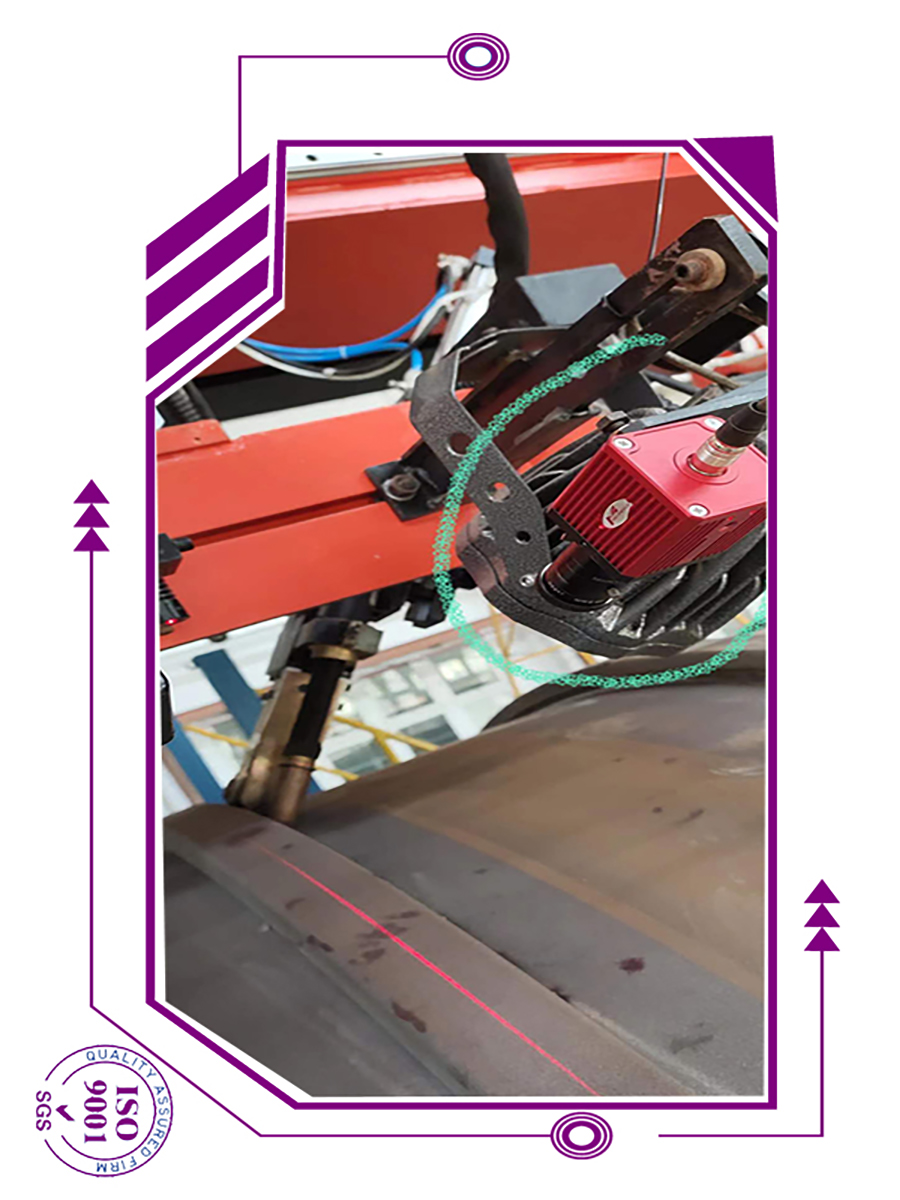

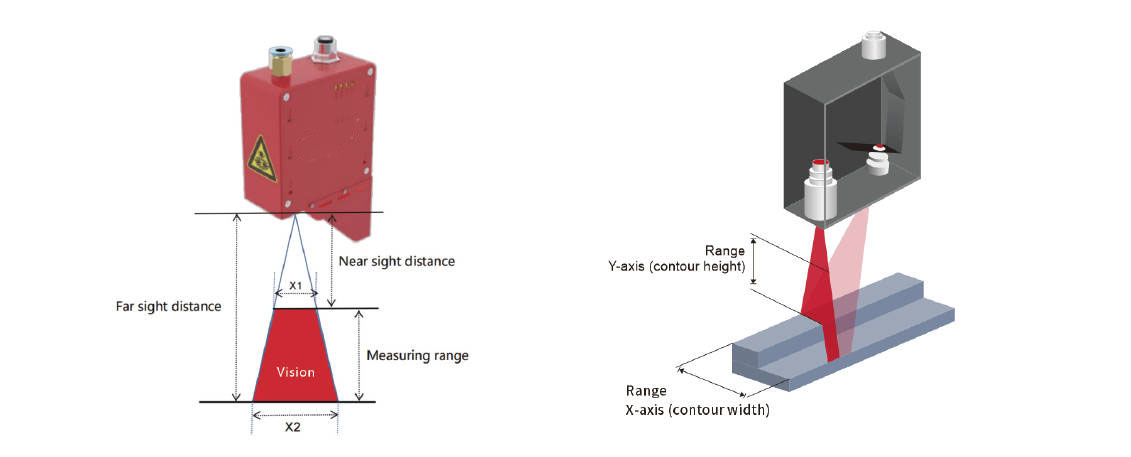

System working principle

A laser is used as a light source to emit a certain wavelength of laser light onto the surface of the weld, forming a laser strip which is received and imaged by a HD camera at another location. After a series of algorithms, the 3D features of the weld are converted into images, generating structured information about the position and shape of the object being measured. This provides the robot with the path it needs to guide the welding process.

It is characterised by high accuracy, contactless and high speed.