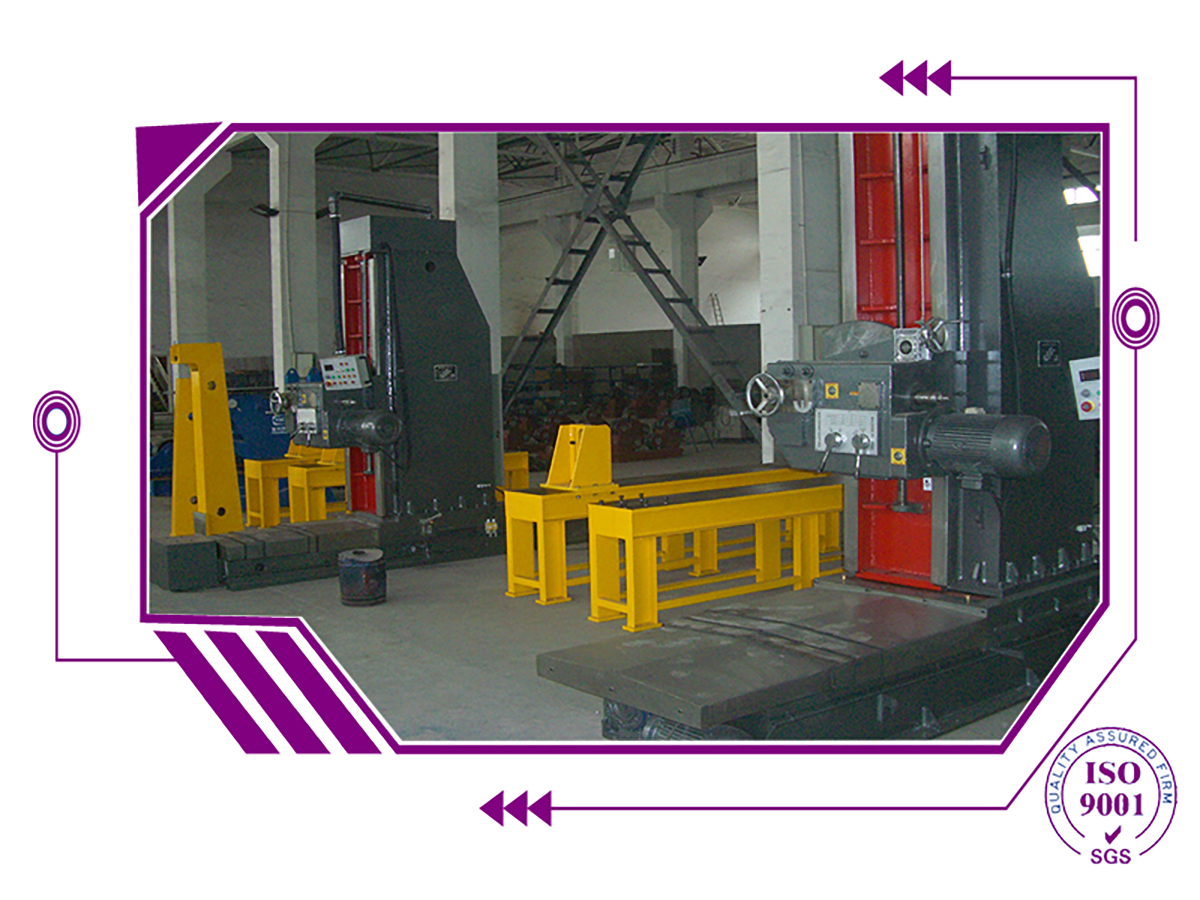

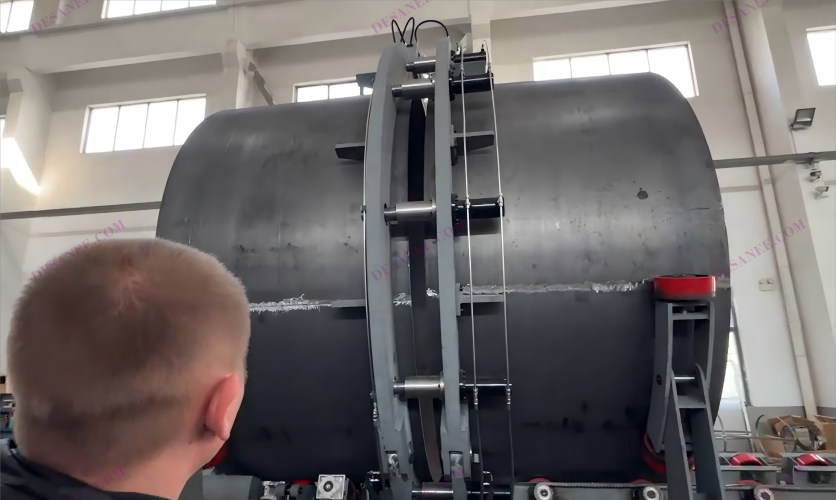

Beam Face Milling Machine machine tool is used for milling of H beams and box beams,also can mill other work pieces with the plane section or flange, so it has the advantages of easy-operation, simple-structure ,high- efficiency。

Beam Face Milling Machine (milling machine) is used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

Optional:

- i)Manual clamp workpiece device,

- ii)Hydraulic clamp workpiece device

Structure OF Beam Face Milling

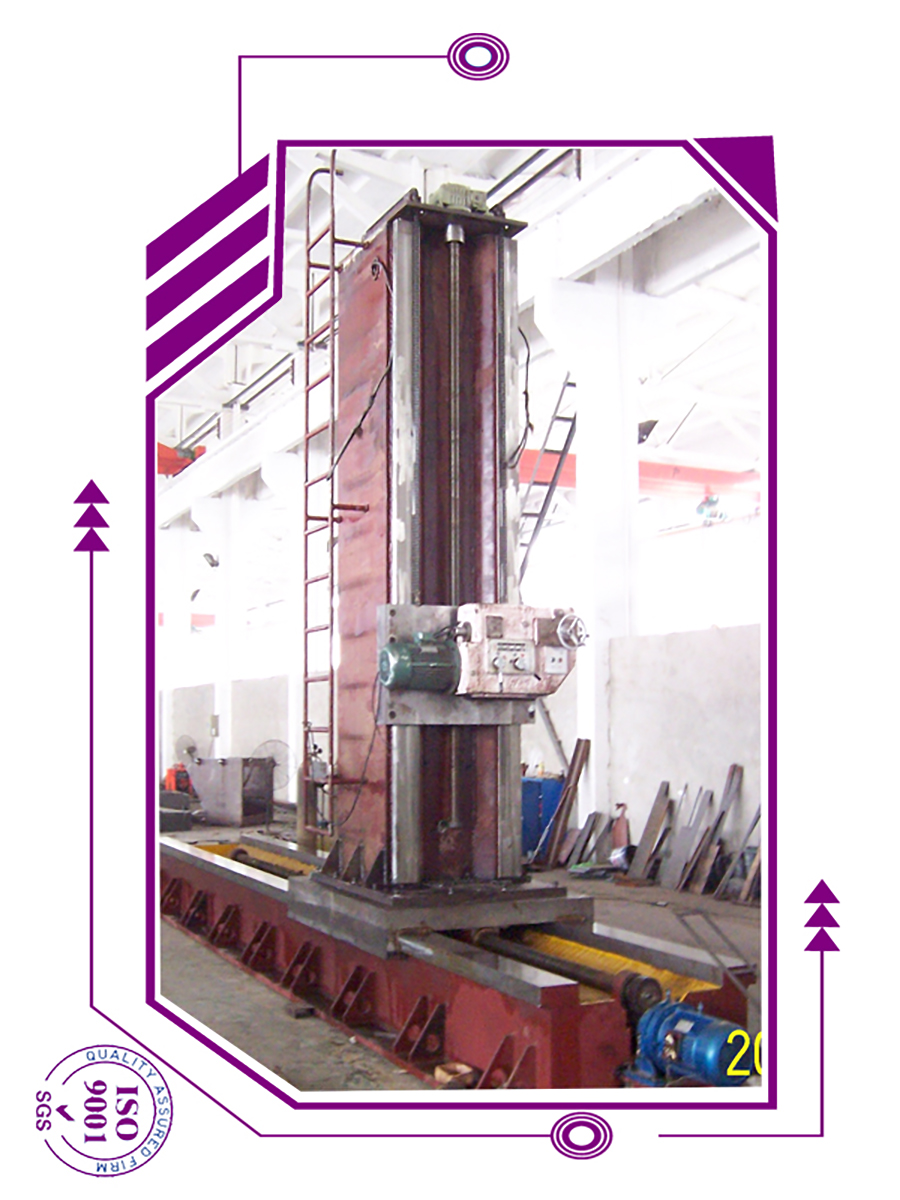

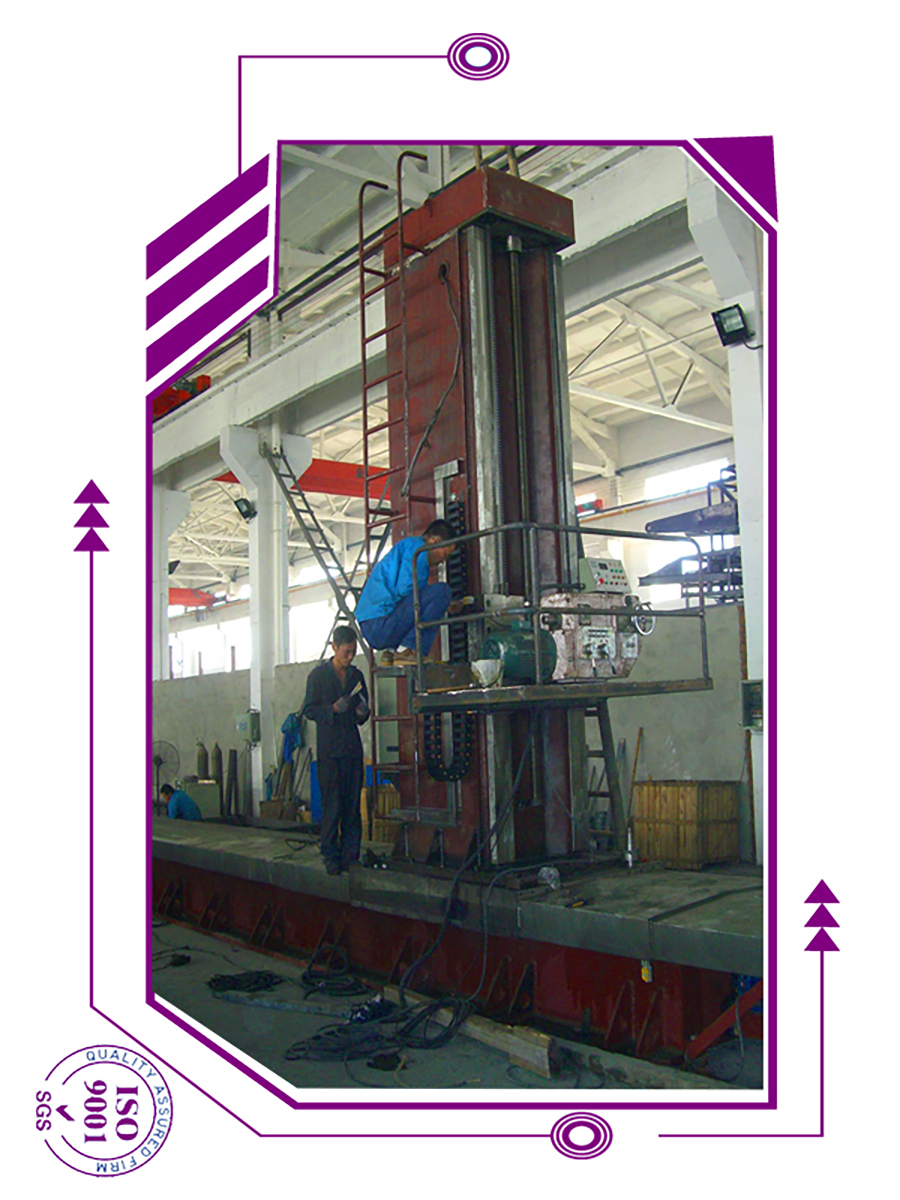

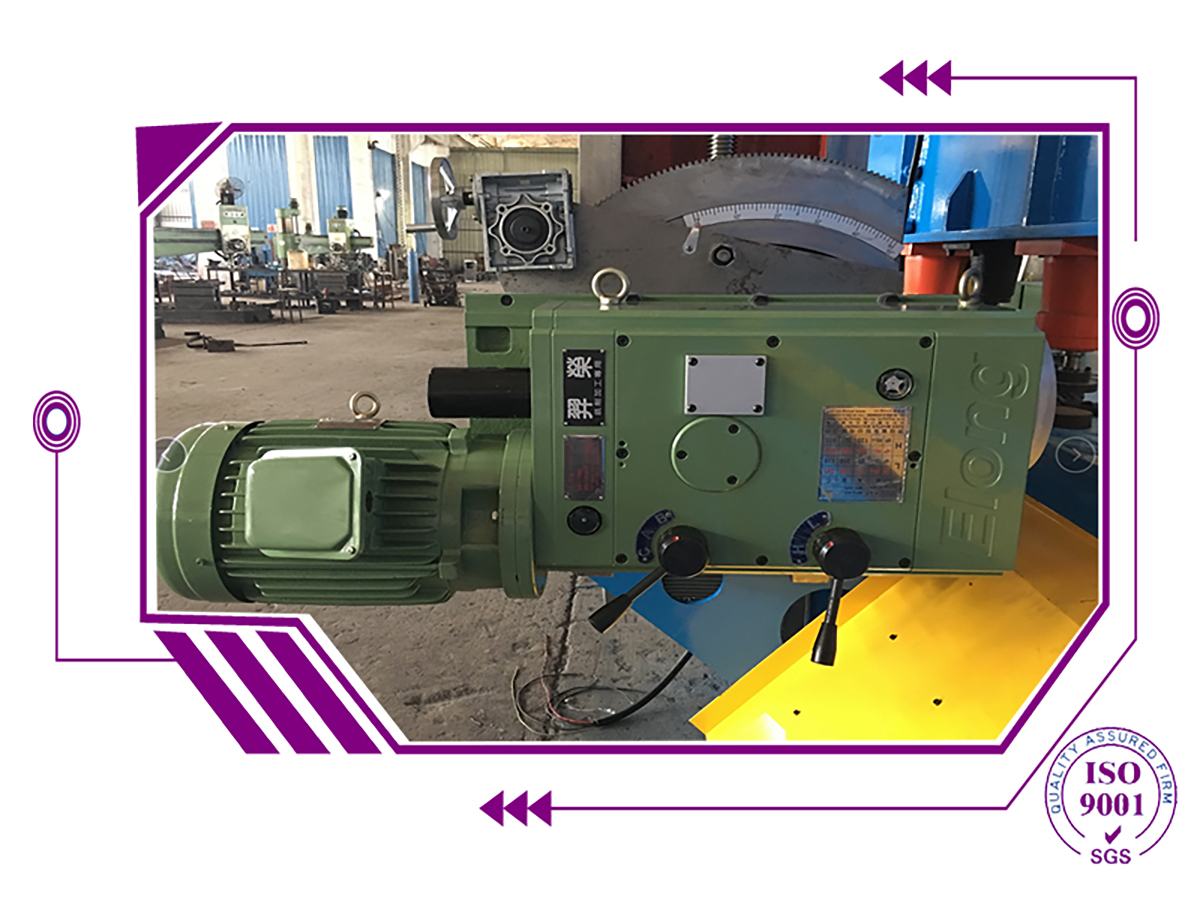

+ DX Beam Face type milling machine mainly consists of facer, elevation , column, worktable, bed, mechanical transmission unit, electrical system, rail-guarding unit and facer.

+ The bed is welding structure, annealed after welding. It has light weight, high intensity, little deformation, reasonable structure and good technology +Besides, the rectangular-section rail has great loading capacity; the V-section rail has high guiding precision.

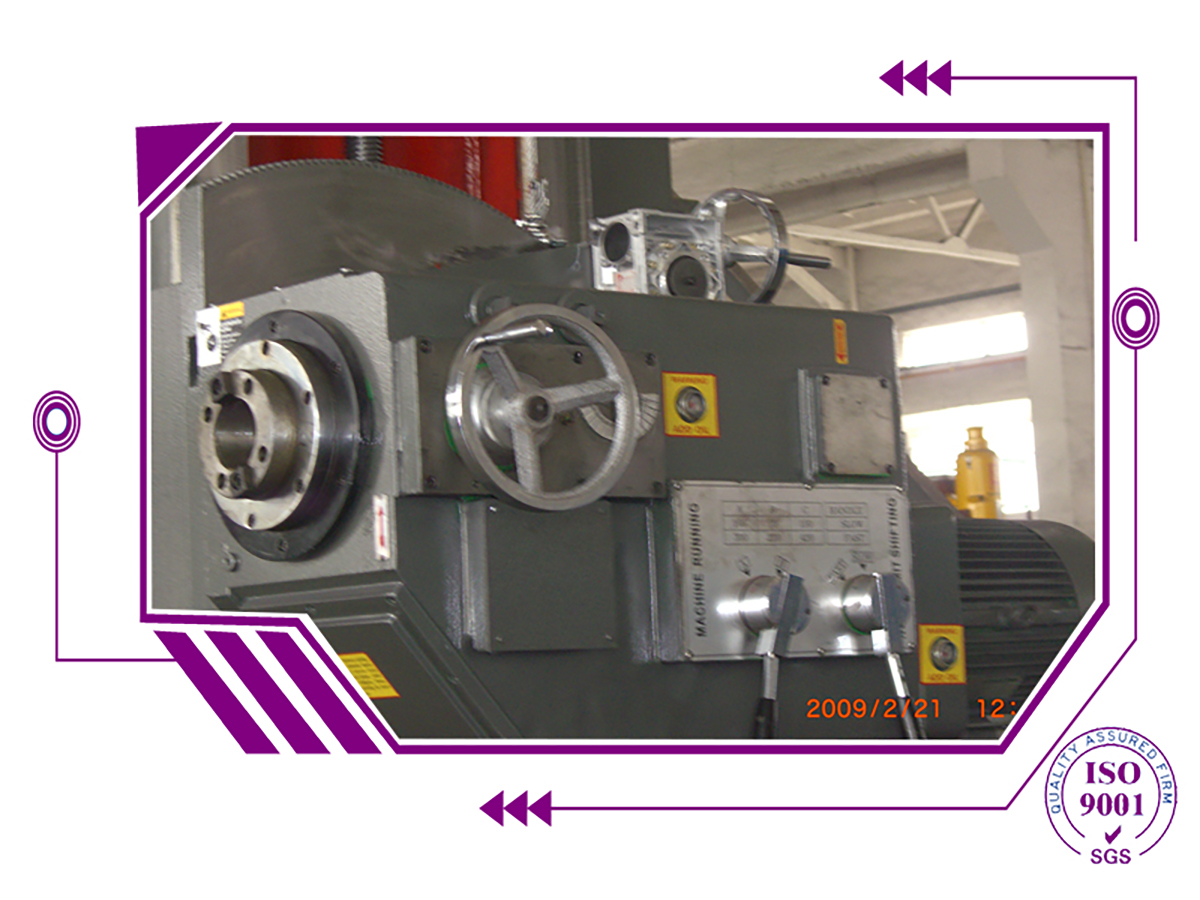

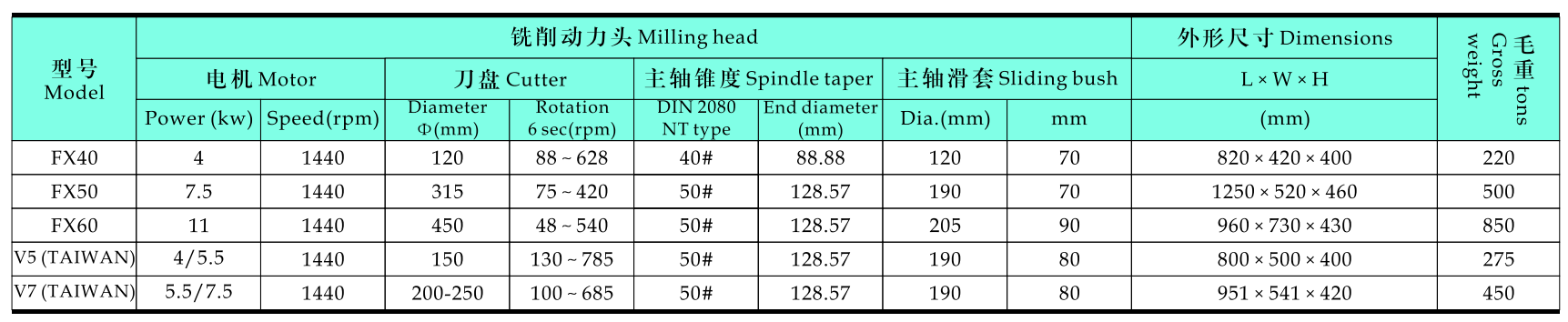

+ Facer is FX-32A type, power 5.5kw, featuring in reasonable structure, reliable performance, extensive speed range-more class , good rigidity, low noise, high efficiency and convenient operation.

+ Beam Face Milling worktable is weld or forged into shape, composing into sliding-couple with bed. As to its rails, one is rectangular-section, another V-section, with good lubrication. The work-table is driven with mechanical transmission system through taper lead-screw nut, with motions of fast-FOR, work-FOR and fast-retreat. Facer is installed on the worktable, which mills work-piece, resets and elevates under driven of worktable. All the motions of worktable are realized via mechanical transmission system and electrical system, and can be controlled by hand.

+Beam Face Milling rail guarding unit has good sealing, good radiation and long life. It is of shrinking structure. There is peep-hole on the fixed guarding-hood, through which lubrication and cleanness of rail can be observed, oil can be applied onto rail A mini-cover plate is used for covering the hole.