1) Overview of beveling machine

GD20 rolling cutting beveling machine for plate weld

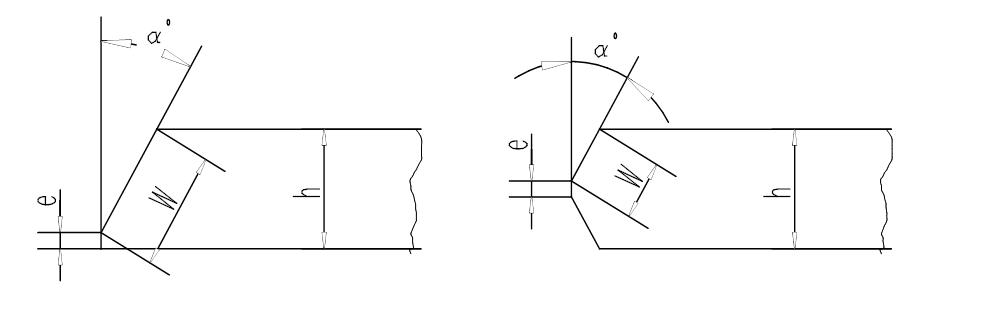

Beveling machine uses the principle of rolling shear to chamfer the edge of the steel plate. It is mainly used for beveling Q235-A, Q420 and other steel plates before welding. The bevel size is correct and the surface is smooth.

Compared with the method of gas cutting, it has the advantages of low energy consumption, faster cutting speed and no need to clean burrs.

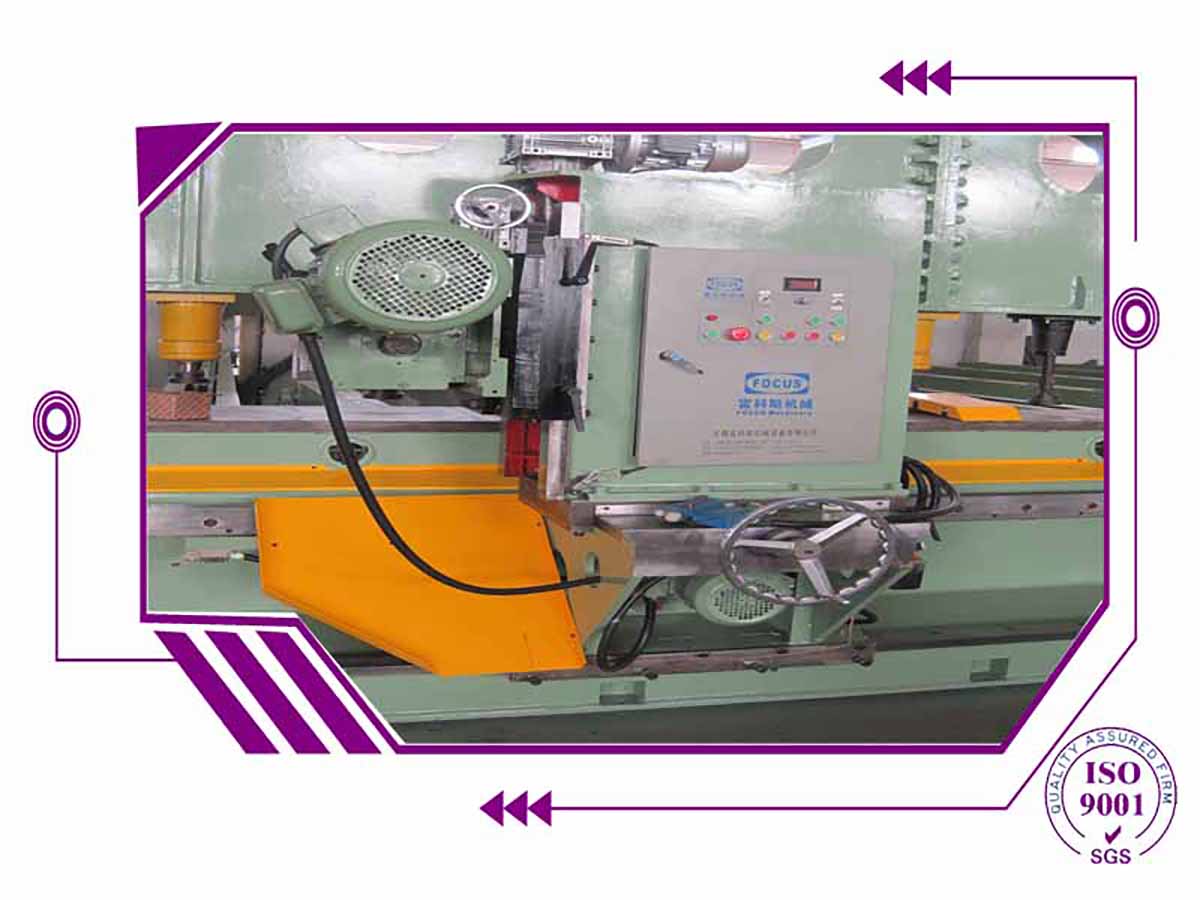

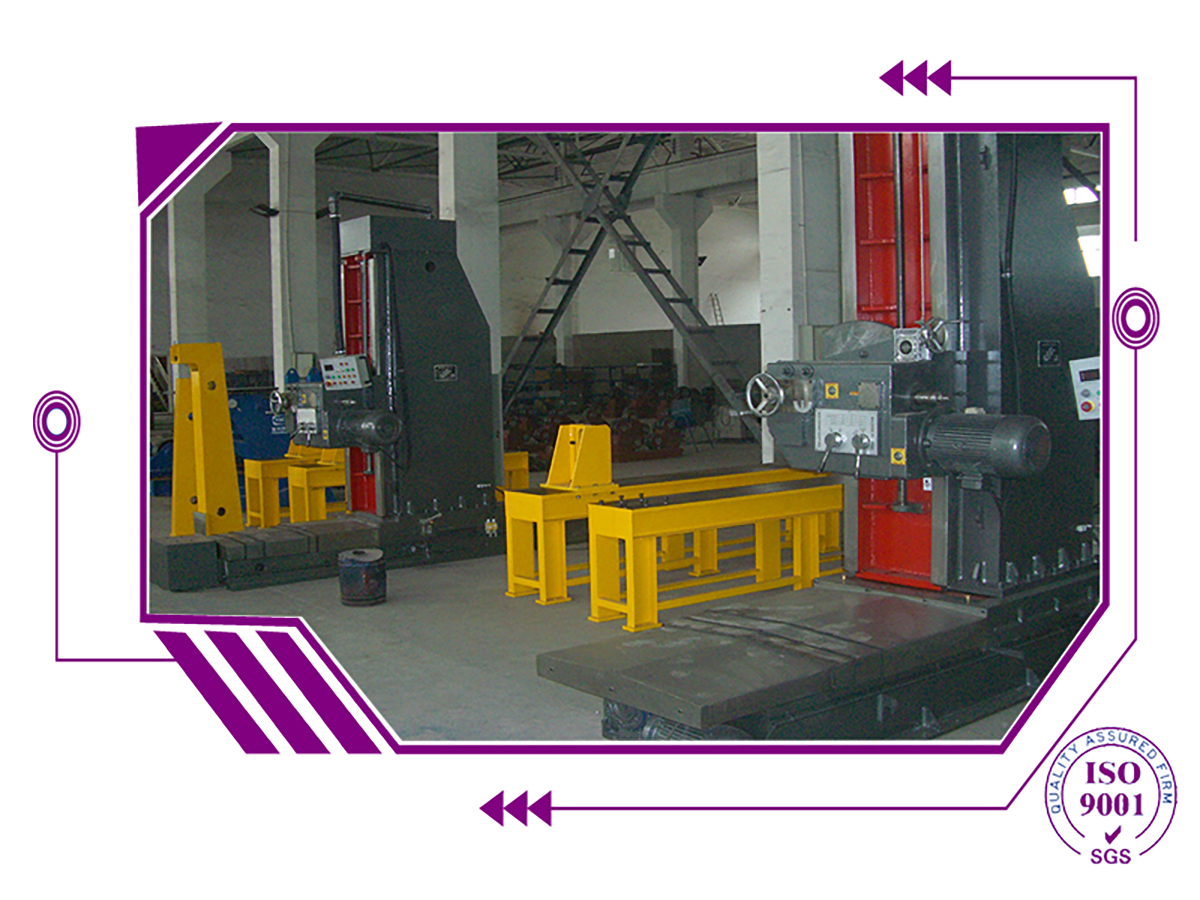

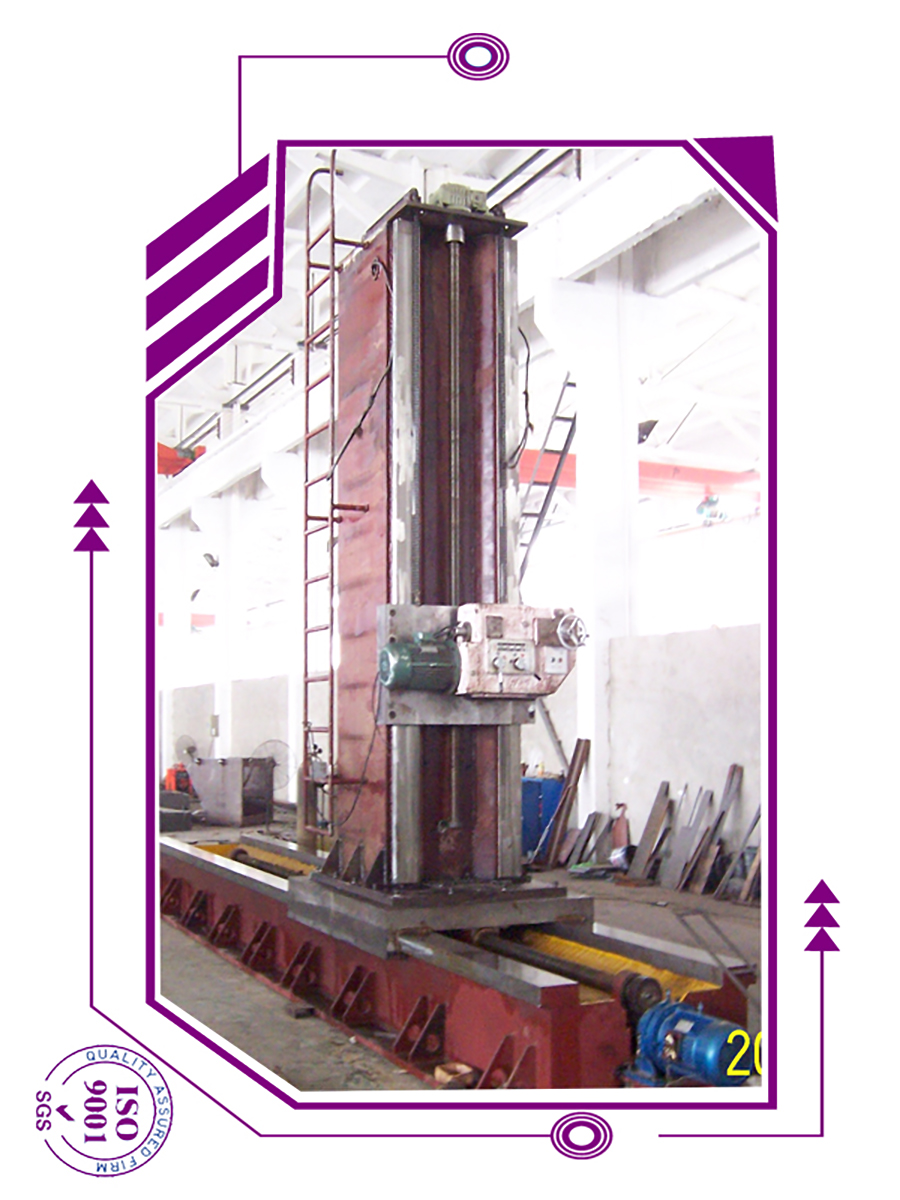

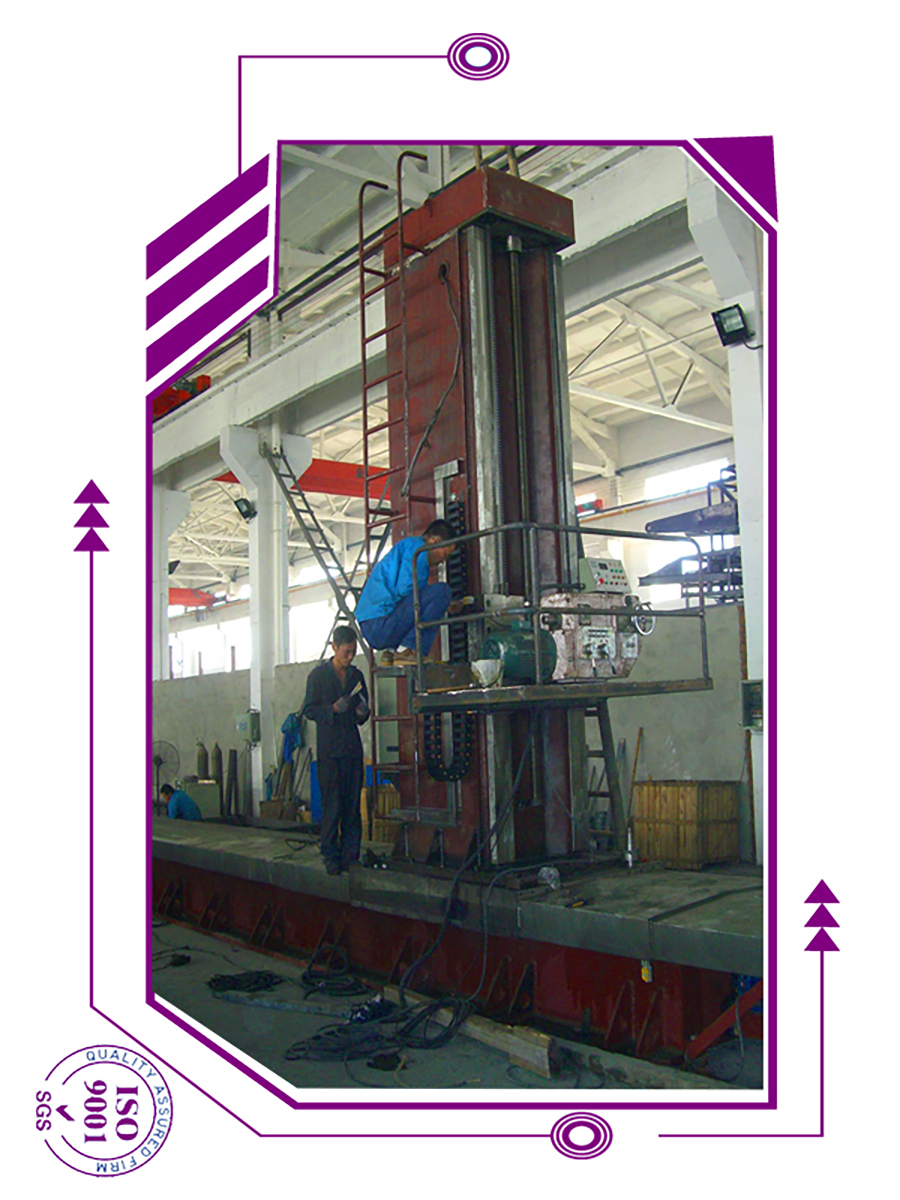

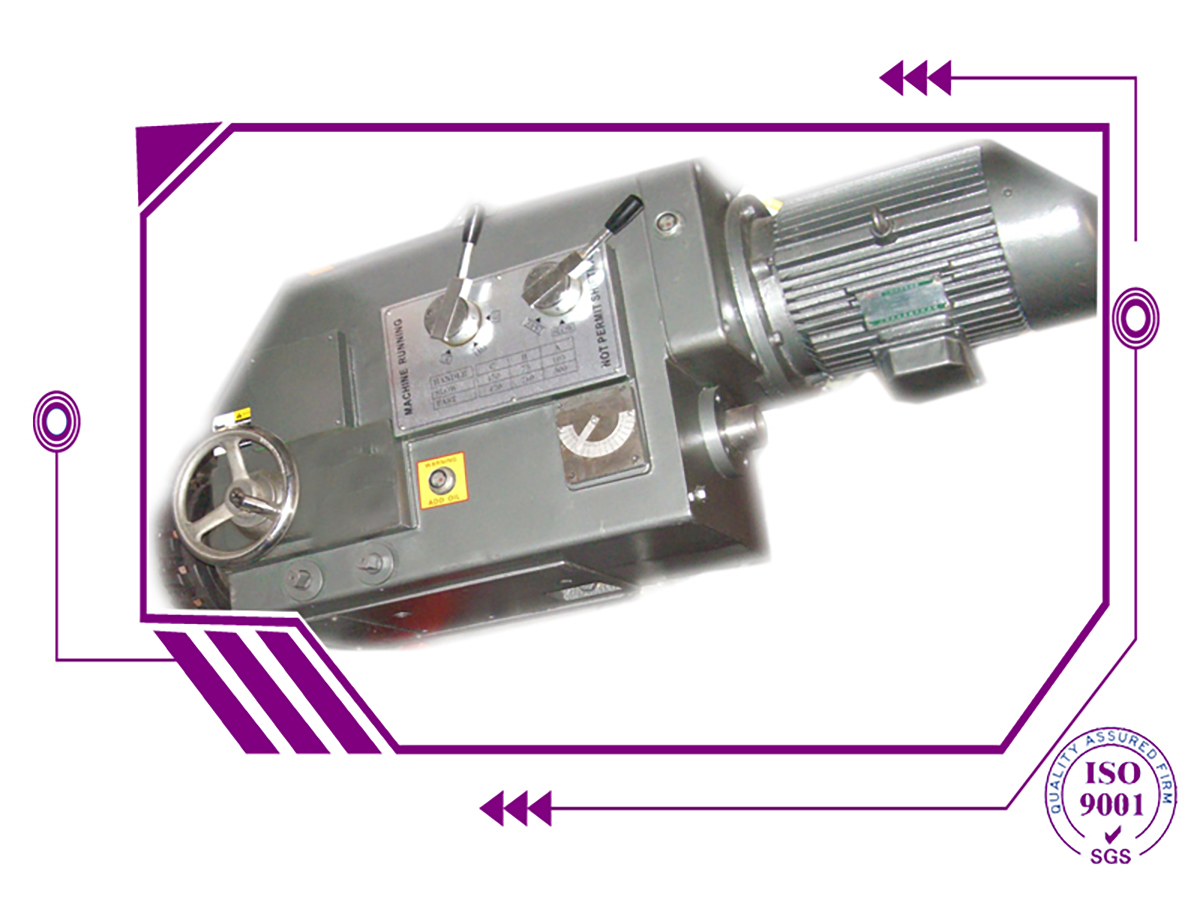

Compared with edge planer and planer, this machine has low price and small footprint. Because there is no need to install clamping, so easy to use, high efficiency, with this machine beveling, the effect is far better than other equipment, is the ideal equipment for beveling before welding. The following picture shows the main machine:

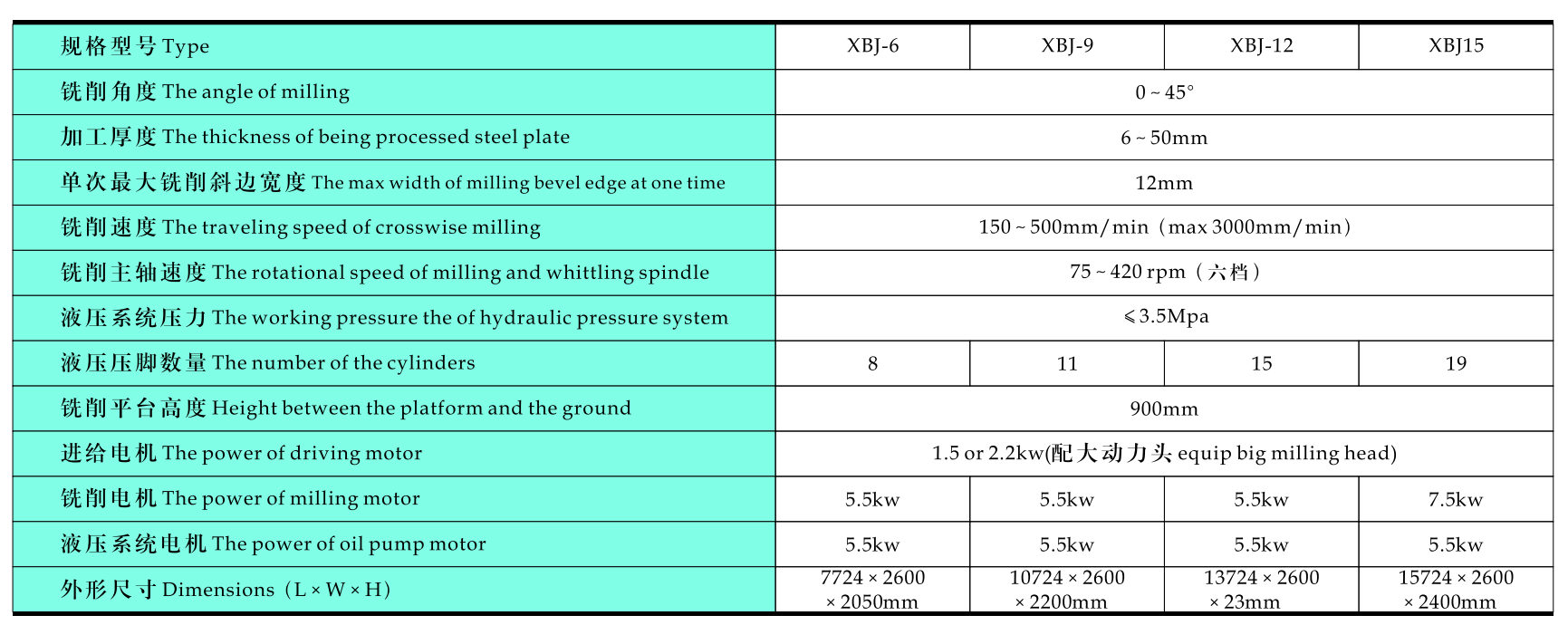

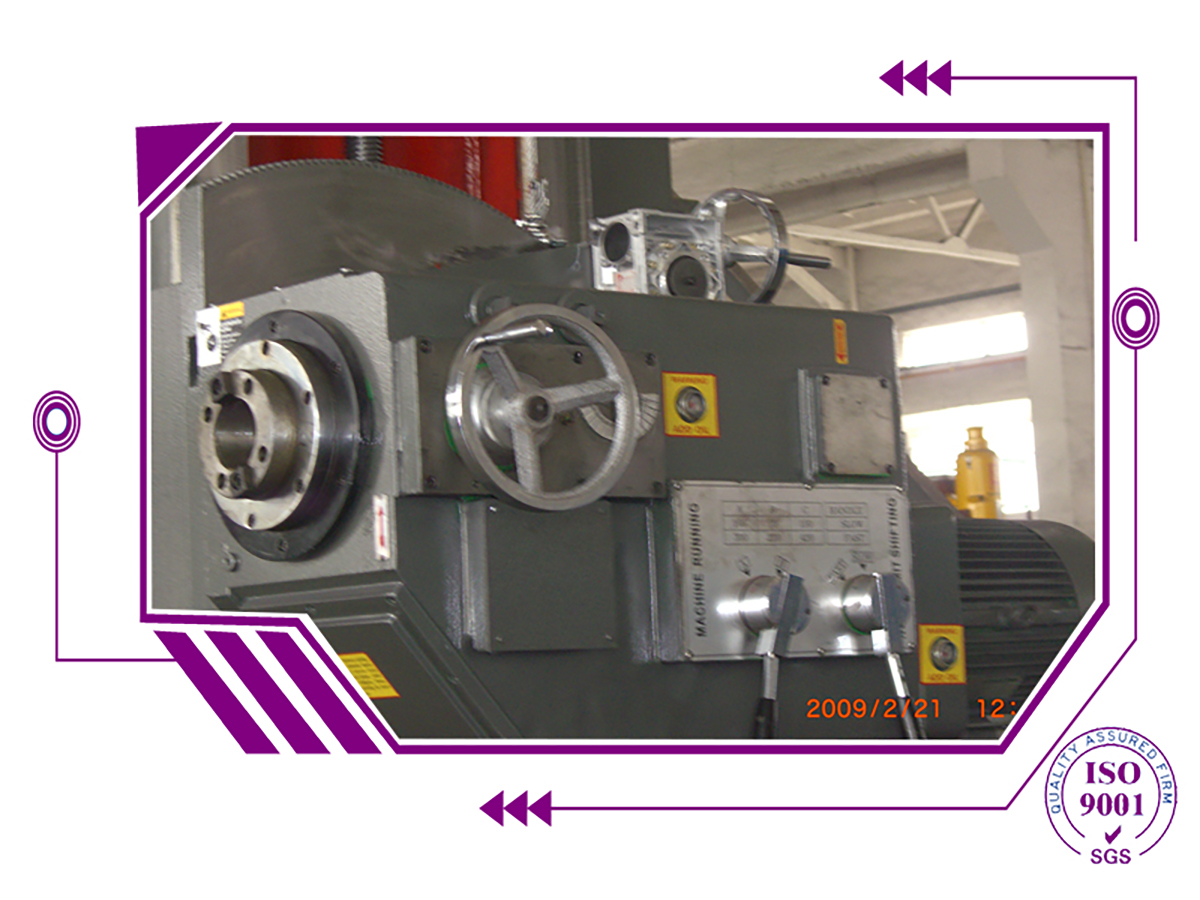

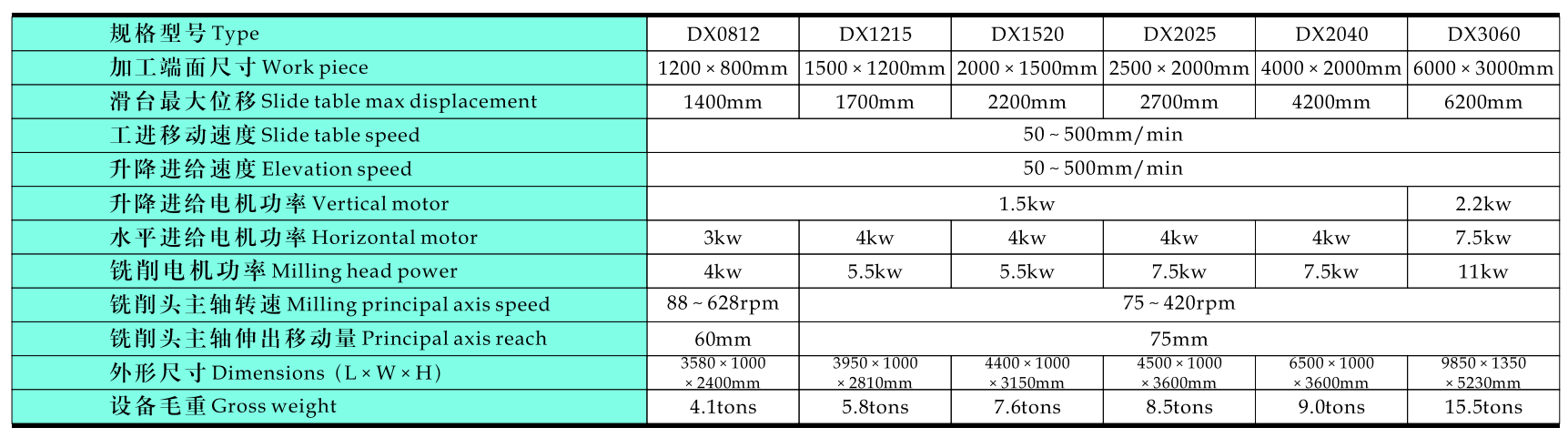

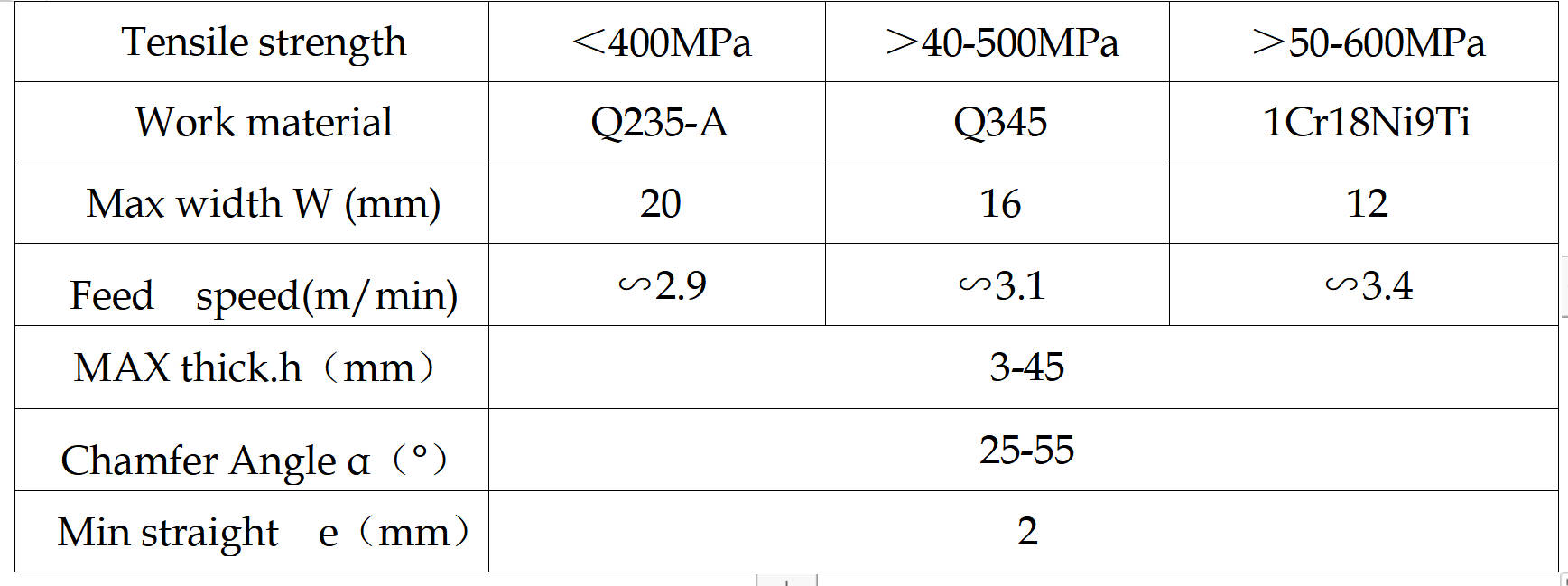

2) Main parameters of the machine

l hob diameter 200 mm (carbon steel hob)

l Spindle speed: 7.7r /min

l Motor model: Y112M-4kW 1440 r/min

l Dimensions: 1240*940*1480mm

l The operating noise of the machine itself shall not exceed 85dB

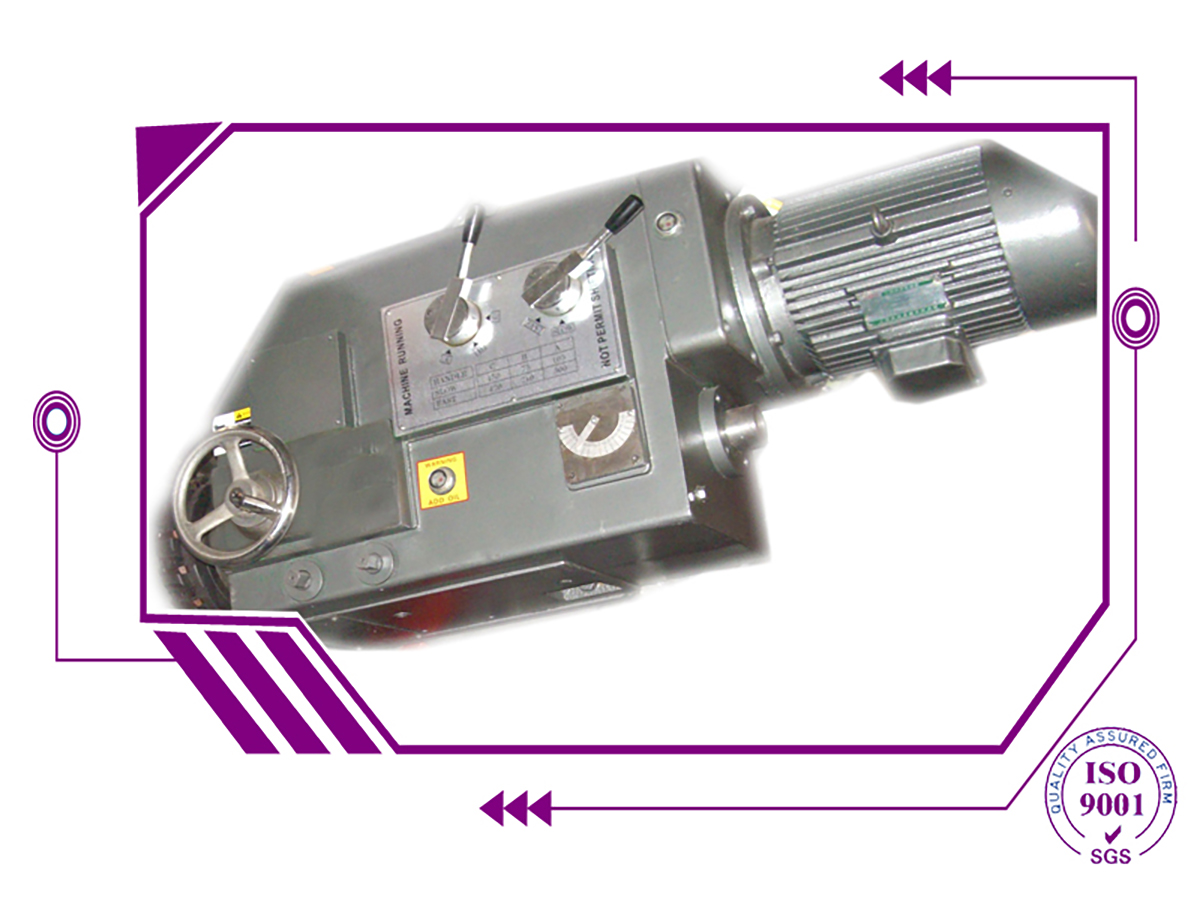

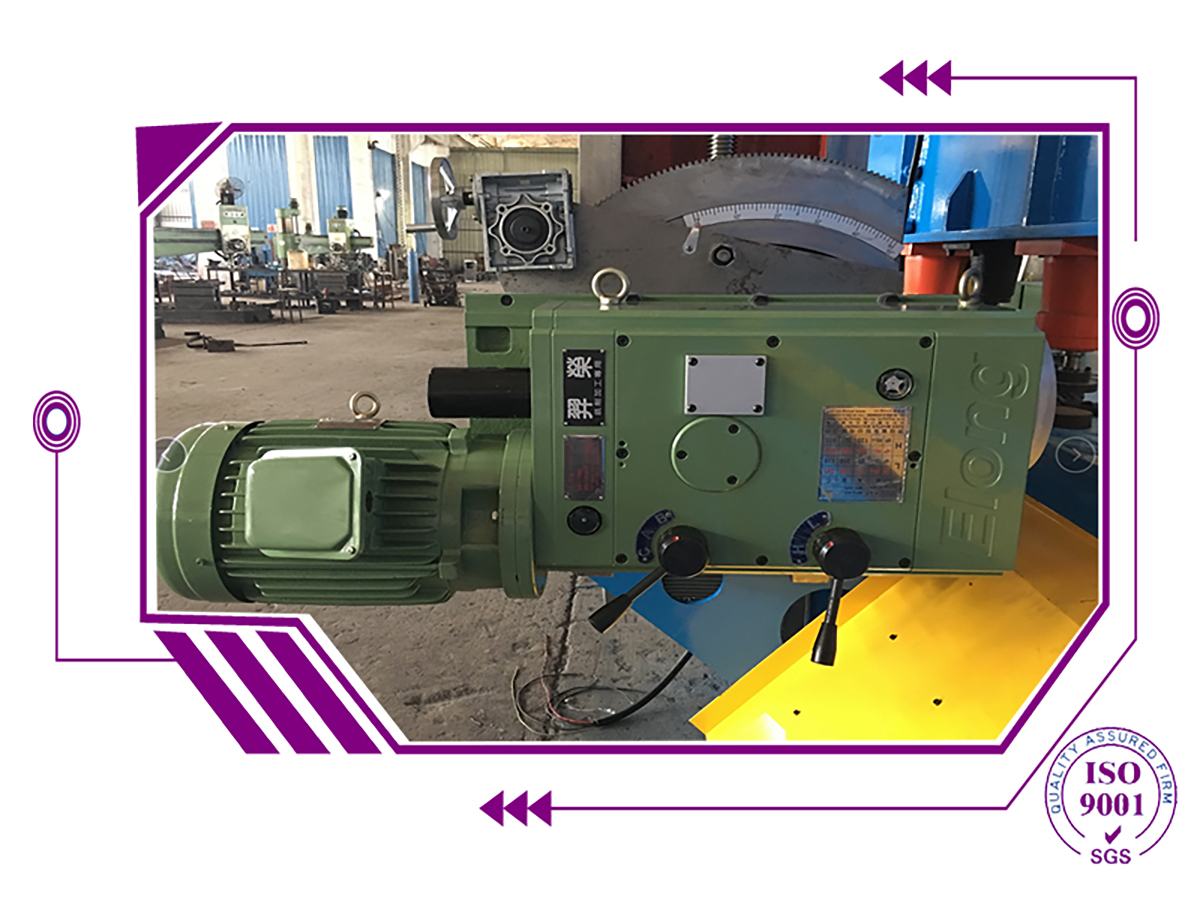

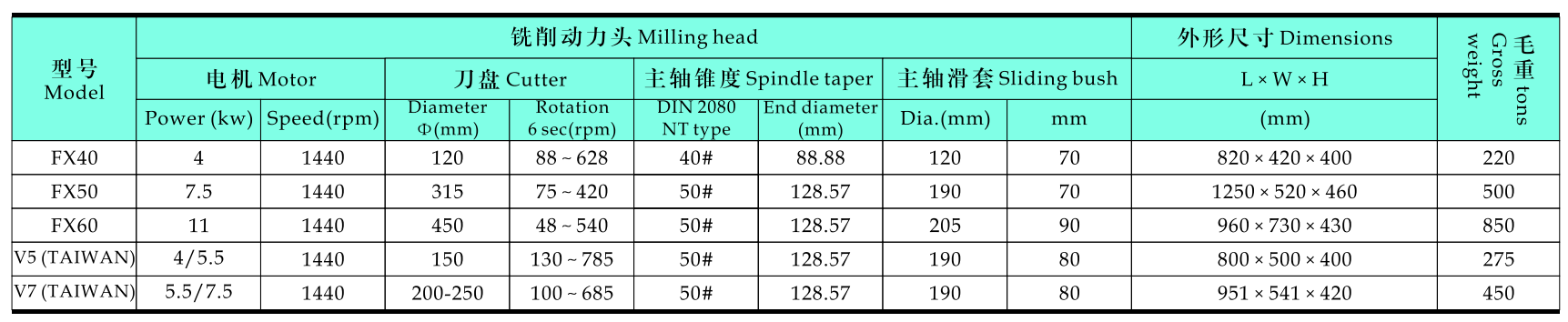

Compared with the traditional beveling machine, this machine series is mountable in their tracks, more rational in structure by heat-treatment of the bench, more reliable and stable in the beveling machine & turning head’s running. The feed and feed-back systems are fully independent respectively. The feed-back is quick and is highly efficient. The angle of the milling tool’s tray is convenient in adjustment, and the custom-built tool rest and the normal tool rest can be inter-converted. They are the updated products of the traditional beveling machine.

.JPG)