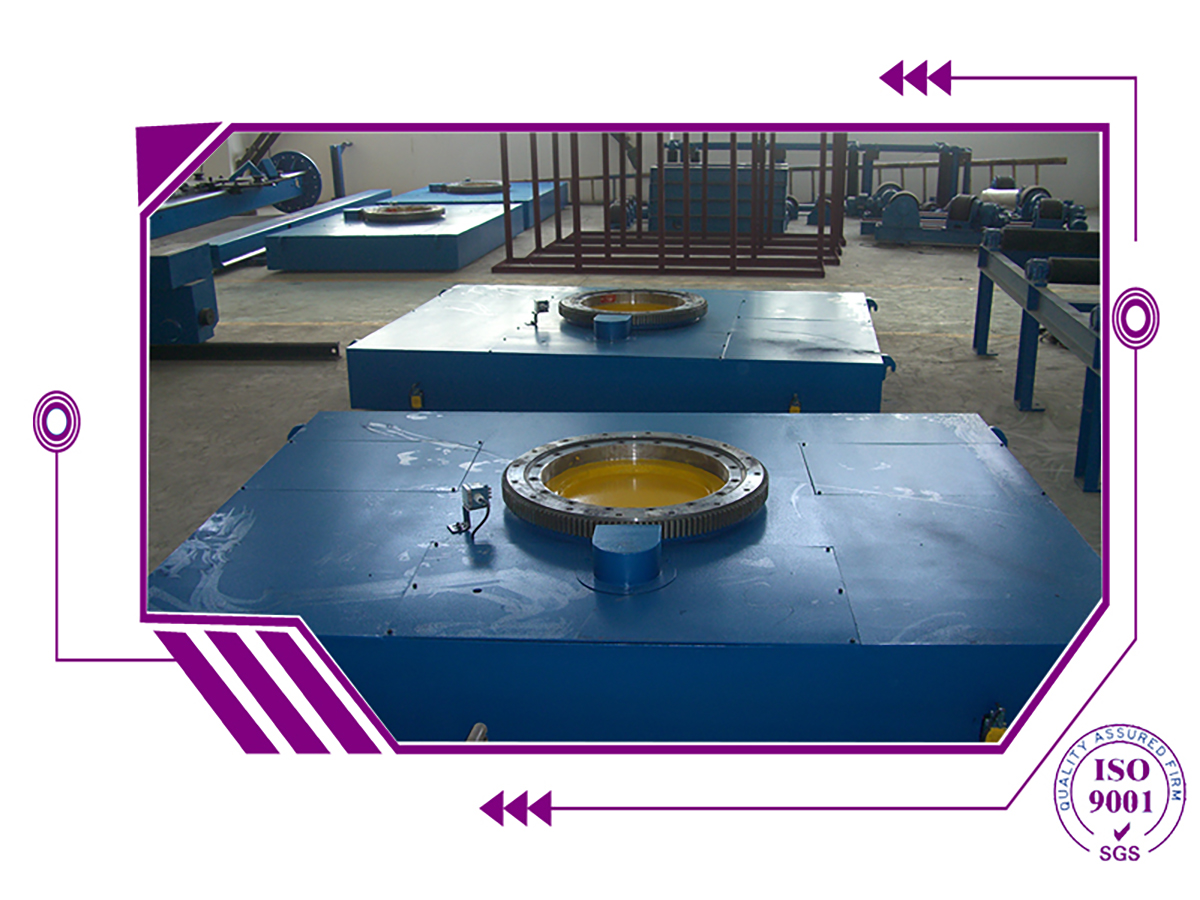

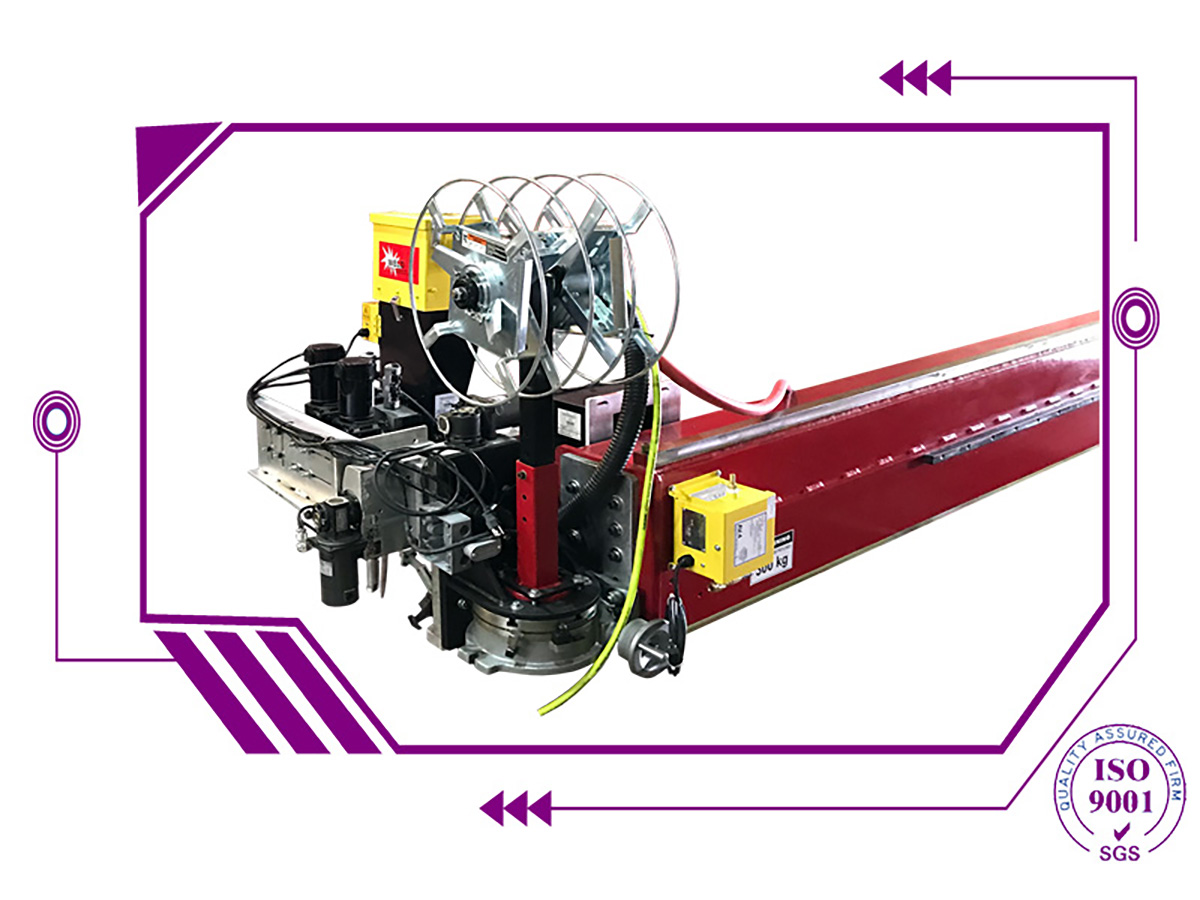

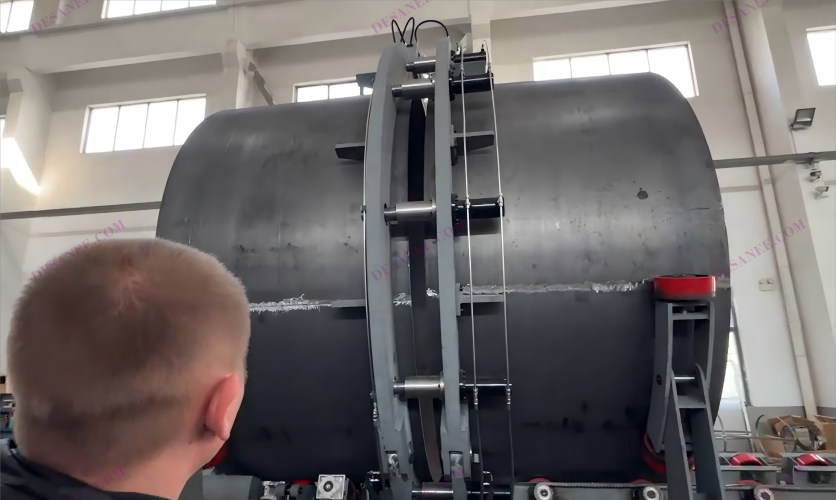

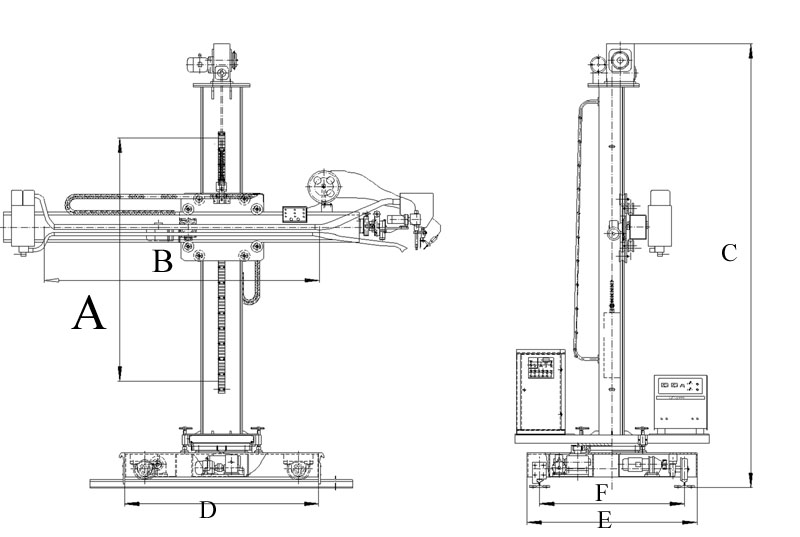

Boom and Column welding can For all arc welding processes, it is important that the welding head be rigidly mounted over the part to be welded to obtain the highest quality weld results. Any vibration or instability of the weld head mounting will have an effect upon the arc length and produce inferior results. Welding manipulator is used when the weld head has to be moved to a position relative to the work piece. Welding manipulator provide the perfect solution as the boom can be lifted and lowered on the column and can be extended or retracted as required, The ends of boom are machined to carry a welding head.

Boom and Column welding Cobo WM12 and welder composed of auto welding mechanical equipment.Boom and Column welding Cobo WM12 can use with welding rotator, widely applied to industries such as boiler, pressure vessel, petroleum, chemical industry and mechanism.

+ Structure : stationary, stationary and revolve , moving and revolve type.

+ Cross section of boom and column are rectangular-section beams, with double-rail, welded into shape、stress-relieved and mechanical machined finely, ensuring higher precision;

+ Drooping of boom along horizontal travel is 2mm/m.

+ Boom lifting device including ratchet-type anti-dripping unit on the column, safe and reliable to prevent chains from incidental broken.

+ Guide roller is eccentric structure, decrease clearance between roller and rail surface, ensuring smooth and no shivering boom travel.

+ Column revolve unit has motor –driven and manual drive type.

+ Control box includes control box and pendant , interface with positioner and rotator also prepared

Boom and Column welding Cobo WM12 (manipulator) is used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

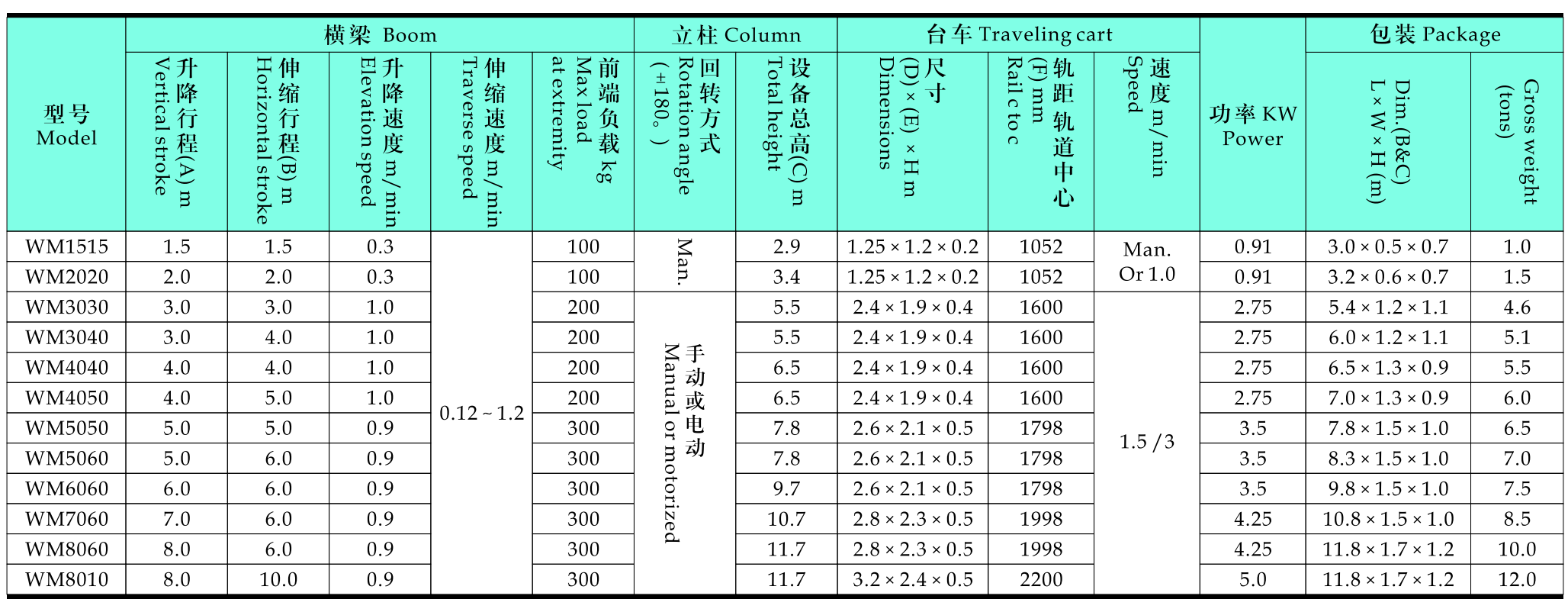

Boom and Column Notes:

a) Column motorized rotation: included only WM 3030 and above

b) Trolley motorized with constant speed: included

c) Remote control box with 6-12 m span: included

d) Manual welding head cross slide: included

e) Boom cable organizer: export product included

f) Boom anti-fall safety device on WM 3030 and above: included

g) Trolley anti-fall safety device: included

h) Power source platform on trolley: included

i) Shot blasted frame at SA 2 ½: included

j) Custom built welding manipulators available

k) CE mark only under customer request

l) Manual revolve then locked by screw

m) The information contained in this brochure is intended to beaccurate. However the manufacturer retain the rights to make changes in design which may not be include

Boom and Column Standard package includes

Boom and Column and traveling cart

Remote control box adjust:

i) Vertical and horizontal boom

movement;

ii) Trolley motion

Operation manual

One year warranty

Boom and Column Optional

- Flux recovery unit of boomand cloumn

- Electric welding head cross slide

- Trolley cable organizer

- Rail track for trolley

- Variable speed on traveling cart from 0.12 up to 1.20 m/minute

- Work platform and operator’s seat only in WM 5050 and larger

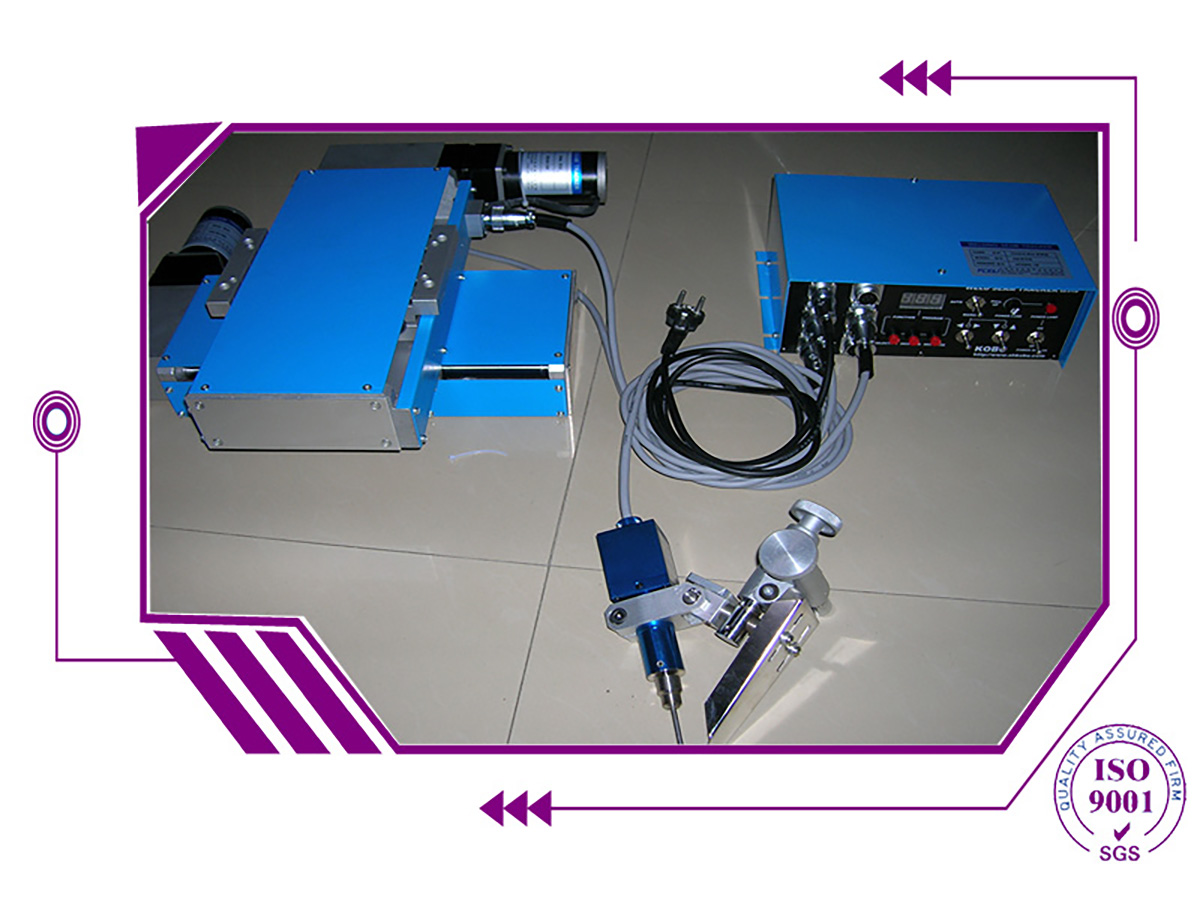

- Seam tracker

- Seam monitor system

- Welding oscillator

- Arc length control

- drive by linear ball bearing guide rail

According to our customers requirement ,we can provide solutions to special equipment ,Selection of the follows functions for Boom and Column:

++Seam tracker

++Welding oscillator

++Arc length control

++flux auto-recovering system and feeding

++monitor operating system