External Clamping Ring fitup line for all pressure tank plant ,USE FOR Tank Clamping and Welding Machines

Dependent on diameter, shape and wall thickness we can offer three different concepts for the welding of vessels, tanks and other cylindrical or conical tubulars:

1 External Clamping Rings

2.Internal Clamping Rings(2026 PLAN)

3.The Crocodile((2027 PLAN)

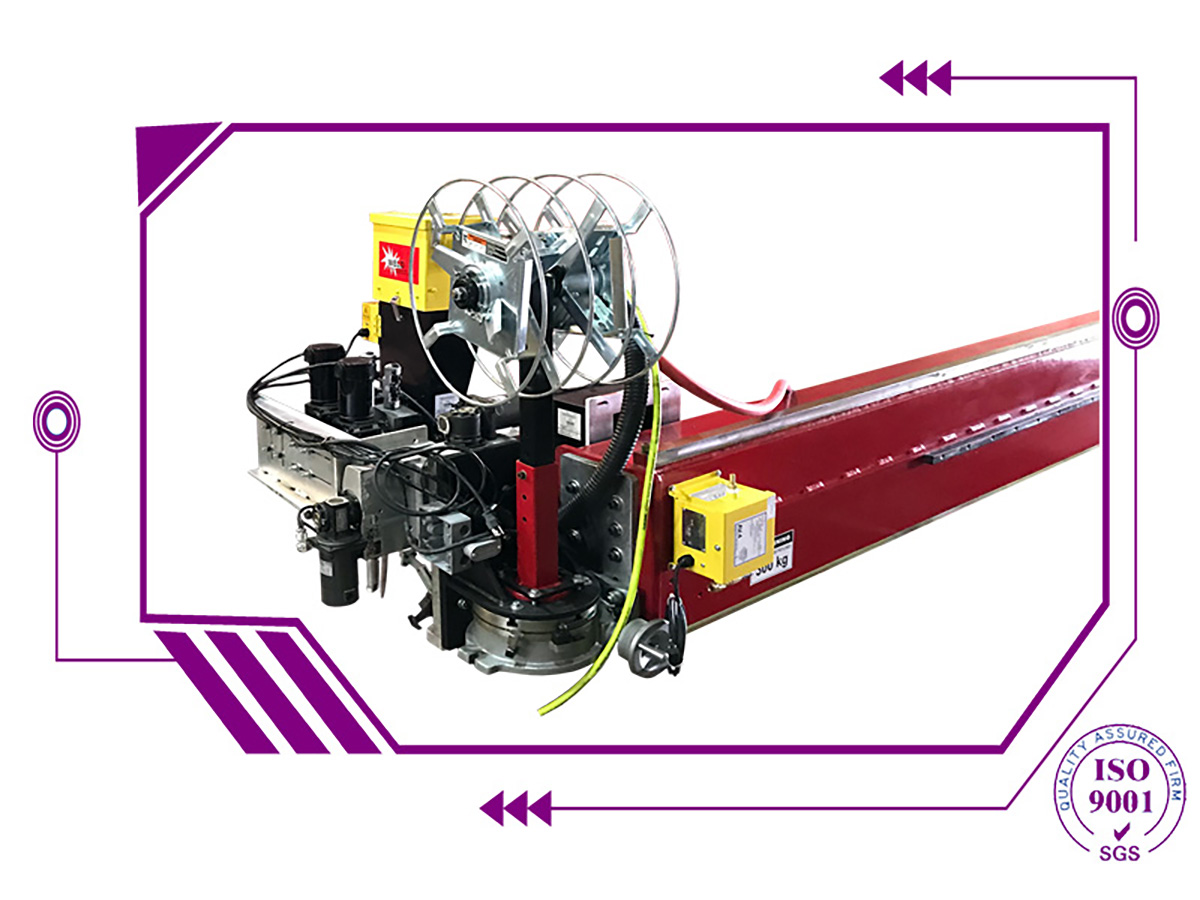

All these machines are suitable to carry-out assembly, clamping and welding procedures. In combination with Column & Booms (Manipulators) and Turning Rolls complete production lines for the manufacture of tanks and vessels can be supplied.

1. External Clamping Rings

We distinguish stationary External Clamping Rings Type ECR , and Rotary Clamping Rings Type RECR.

These are employed for diameters ranging from approx. 400 to 4000mm and wall thicknesses from 3 to 12 mm . special 25 mm.

External Clamping Ring fitup line mainly use for pipe line and tank plant.

1. Technical features of the complex:

|

Serial Number |

Device Features |

Units |

Parameters |

Remarks |

|

1 |

Applicable workpiece diameter |

м м |

3220 |

— |

|

2 |

Workpiece diameter accuracy |

м м |

Plus or minus 6 |

— |

|

3 |

Hydraulic |

Megapascal |

10 |

— |

|

4 |

Number of clamping cylinders |

ш т |

2 |

|

|

5 |

Clamp cylinder size |

м м |

Æ 120 x 70 |

— |

|

6 |

Number of tension cylinders |

a |

10 |

Includes retaining ring and adjusting ring kit |

|

7 |

Tighten the cylinder size |

м м |

Æ 80 x 45 |

— |

|

8 |

Number of shock absorbing cylinders |

a |

4 |

|

|

9 |

Shock absorber cylinder size |

millimeter |

Æ 50 x 40 |

— |

|

10 |

Circular support rollers for moving support |

a |

4 |

Included in hydraulic system |

|

11 |

Fixed ring and adjusting ring width |

м m |

3650 |

— |

|

12 |

Stationary ring and adjusting ring height |

м м |

4000 |

— |

|

13 |

Output roller stand length |

м м |

10000 |

The roller frame consists of conveyor brackets (8 parts), lifting and rotating brackets (4 parts), see item 6, Photo 1, Appendix 2 |

|

14 |

Entrance roller frame length |

м м |

5000 |

The roller frame includes conveyor brackets (4 parts), lifting and rotating brackets (4 parts), see Item 5, Photo 1, Appendix 2 |

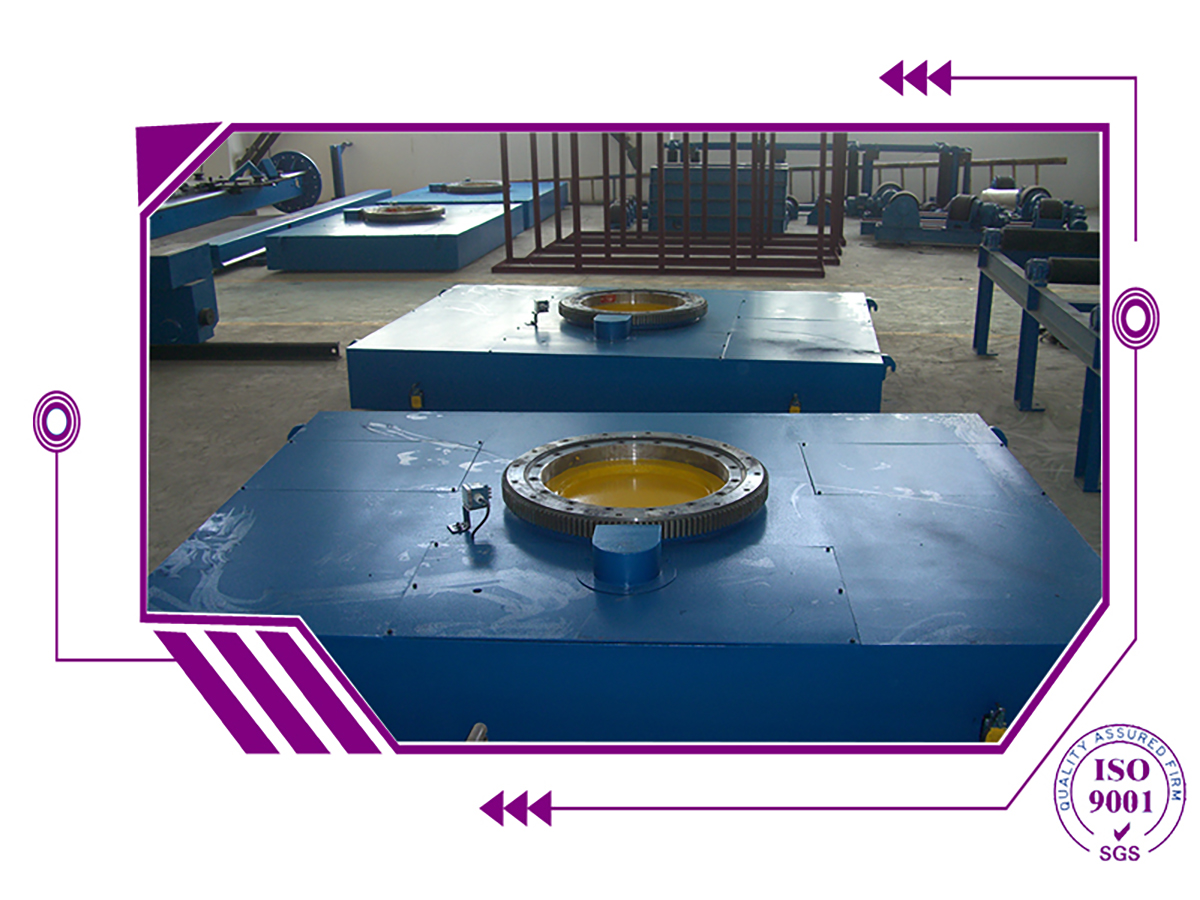

2. Structure and working principle of External Clamping Ring fitup line complex

- The assembly consists of a base, a fixing ring, a displacement mechanism, a adjusting ring, a adjusting hydraulic cylinder, a clamping ring, a clamping hydraulic cylinder, a folding bracket at the bottom of the mounting, a hydraulic mobile bracket with a circular support roller, an input roller frame and an output roller frame.

- The base is fixed to the ground and welded by high-strength steel plates. The fixed base is attached to the fixed clamp ring to support all the equipment.

- The fixing ring is mounted on the base and is connected through two shafts. The two axles have a common offset function that allows you to adjust the position of the entire clip ring left and right.

- The fixed part houses four sets of seismic hydraulic cylinders that support the workpiece and prevent it from colliding with the fixed clamp ring.

- Ten sets of hydraulic cylinders are connected to the adjusting ring and the fixing ring. After the retaining ring and the adjusting ring clamp the work piece at the same time, pull them together and install the flat head nails on the work piece.

- The clamping hydraulic cylinder is installed on the upper end of the clamping ring, and the workpiece is clamped through the extension and retract rod to ensure the circumference of the workpiece.

- The folding bottom mounting bracket is used to support the fixed bottom, which is convenient for the assembly of the shell and the bottom.

- Hydraulic moving bearings with circular support rollers are used to support the left and right sides of the workpiece, improving the circumference of the workpiece and making it easier for the cylindrical workpiece to enter the retaining and adjusting rings.

- The front and rear conveyor brackets include two sets for the input of the cylindrical workpiece and the output of the assembled cylindrical workpiece. The outlet rollers are set up with 8 sets of outlet front and rear conveyor supports (about 10 meters), as well as 4 sets of lifting and rotating supports. The entrance roller frame is equipped with 4 groups of front and rear conveyor supports (about 5 meters), and 4 groups of lifting and rotating supports. The inlet and outlet frame is used to feed two cylindrical workpieces into the fixing and adjusting rings on both sides of the ring.