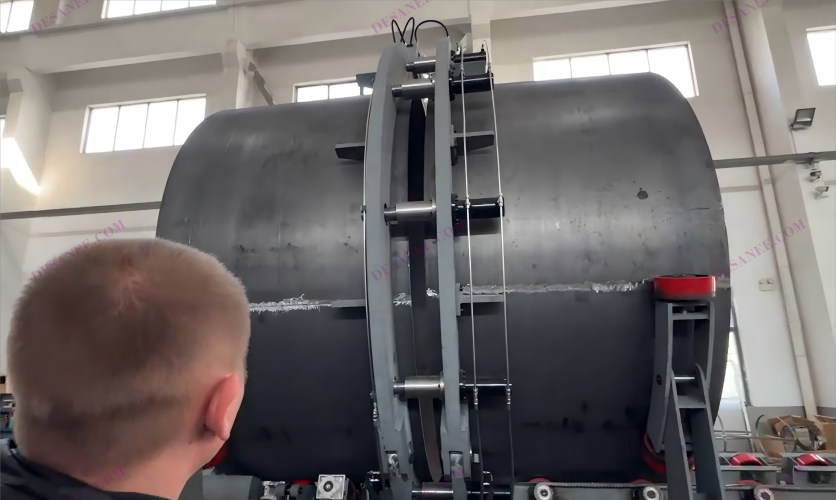

Corrugated plate welding machine of MIG LASER including main machine ,welder ,feed plate frame ,control box .

Corrugated plate welding machine of MIG LASER Introduction

++ Corrugated platewelding machine of MIG LASER foundation supporting parts by the bottom beam, pressure beam and other parts, fuselage using steel structural parts, high strength, small deformation;

++ key pressing device is divided into two sets of left and right symmetry, which can respectively pressure both sides of the workpiece, the air pressure is adjustable, the key pressing foot is made of steel structural parts.

++ walking mechanism assembly by the beam, the gun mechanism, slider composition, the machine uses the gear rack to do the linear walking mechanism part, the motor is DC frequency conversion speed regulation motor, the machine walking assembly has high precision, walking stability, torque and other characteristics.

The lifting and lowering action of the lifting mechanism of the welding gun is driven by pneumatic mode, which has simple structure, fast and stable action.

High repetition accuracy, easy operation and so on. The guide part of the lifting action adopts a linear guide rail to ensure the stability and flexibility of the action.

The material of the back molding groove is copper, and the molding groove is processed above.

Corrugated plate welding machine of MIG LASER Welding requirements:

- Workpiece material: carbon steel, Q235

- Corrugated plate welding Workpiece specifications:

Thickness of welding material 1-3mm

Length of welded plate: 3.2 meters

- Corrugated plate welding Welding process:

3.1.CO2 gas shielded welding. Or laser welding (welding machine needs to be configured by the customer)

3.2. Weld assembly requirements: splicing type break clearance 0-0.5mm

- Pre-welding requirements:

The weld joint should ensure that the incision is as smooth as possible, no curling, diagonal cutting, etc., and the weld area is free of burrs,

Oil pollution and other factors affecting the quality of welding. The sprayed primer or zinc plate should be polished before welding and then welded.

Corrugated plate welding machine of MIG LASER technical parameters of the equipment:

The thickness of the welded plate is 1mm ~ 3mm

The width of the patchwork can be adjusted from 1000 to 3200mm

Welding length (steel plate length) (adjustable)

The final width of the collage shall not exceed 3200mm

Workpiece material carbon steel, Q235

Welding method MAG (20%CO2+80%Ar) /MIG other way

Welding wire diameter Φ1.0-Φ1.2 solid core welding wire

Pressing mode pneumatic keyboard pressing

Welding speed 300 ~ 1400mm/min

Molding groove material copper

Molding groove cooling method air cooling

Empty stroke speed

Variable speed (adjustable range 0 ~ 4000mm/min)

Welding car direction and driving mode linear guide rail positioning, rack and pinion drive

Welding action adjustment manual fine tuning

The lifting height of the welding gun is about 120mm

The press foot height of the piano key is 100MM±5