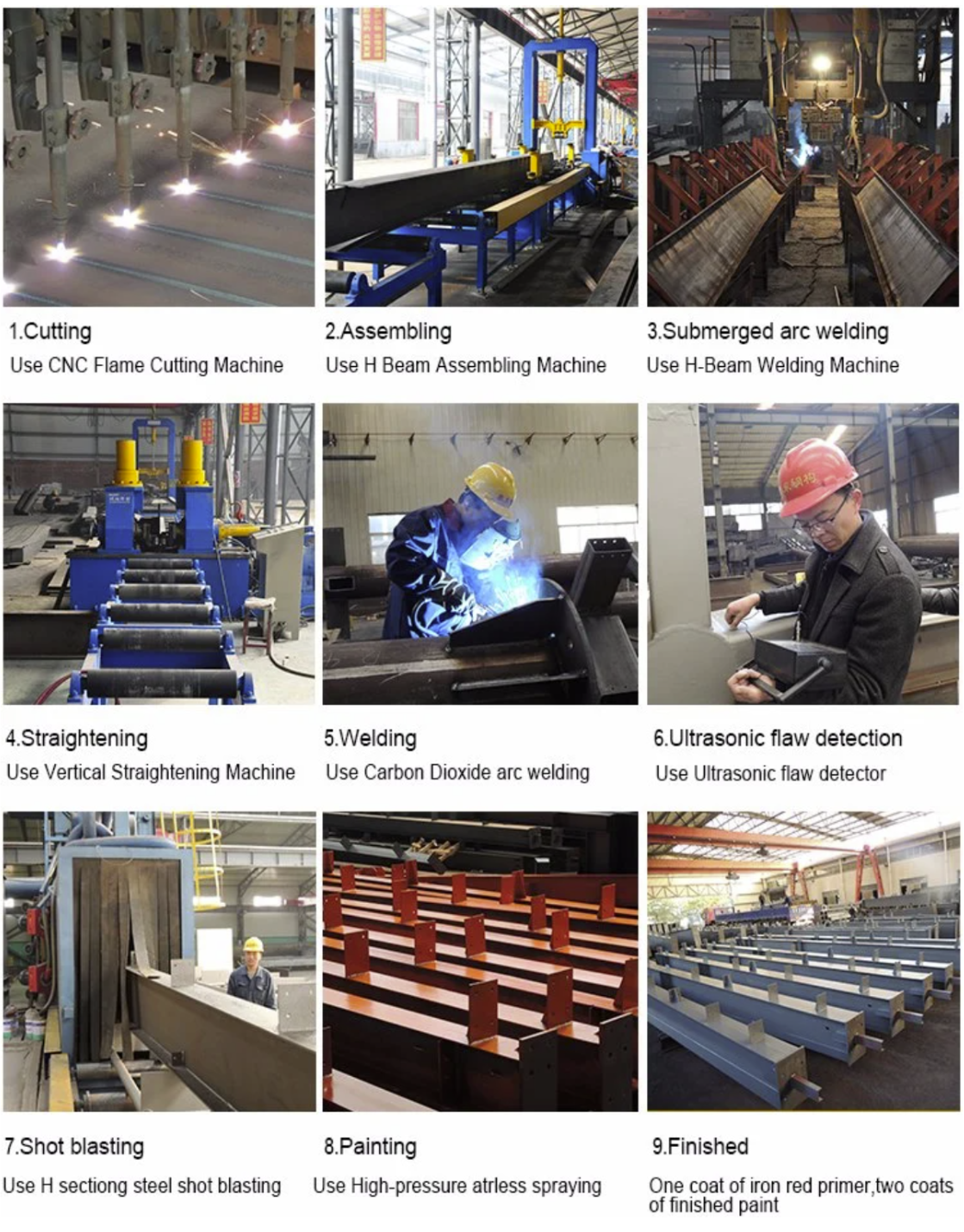

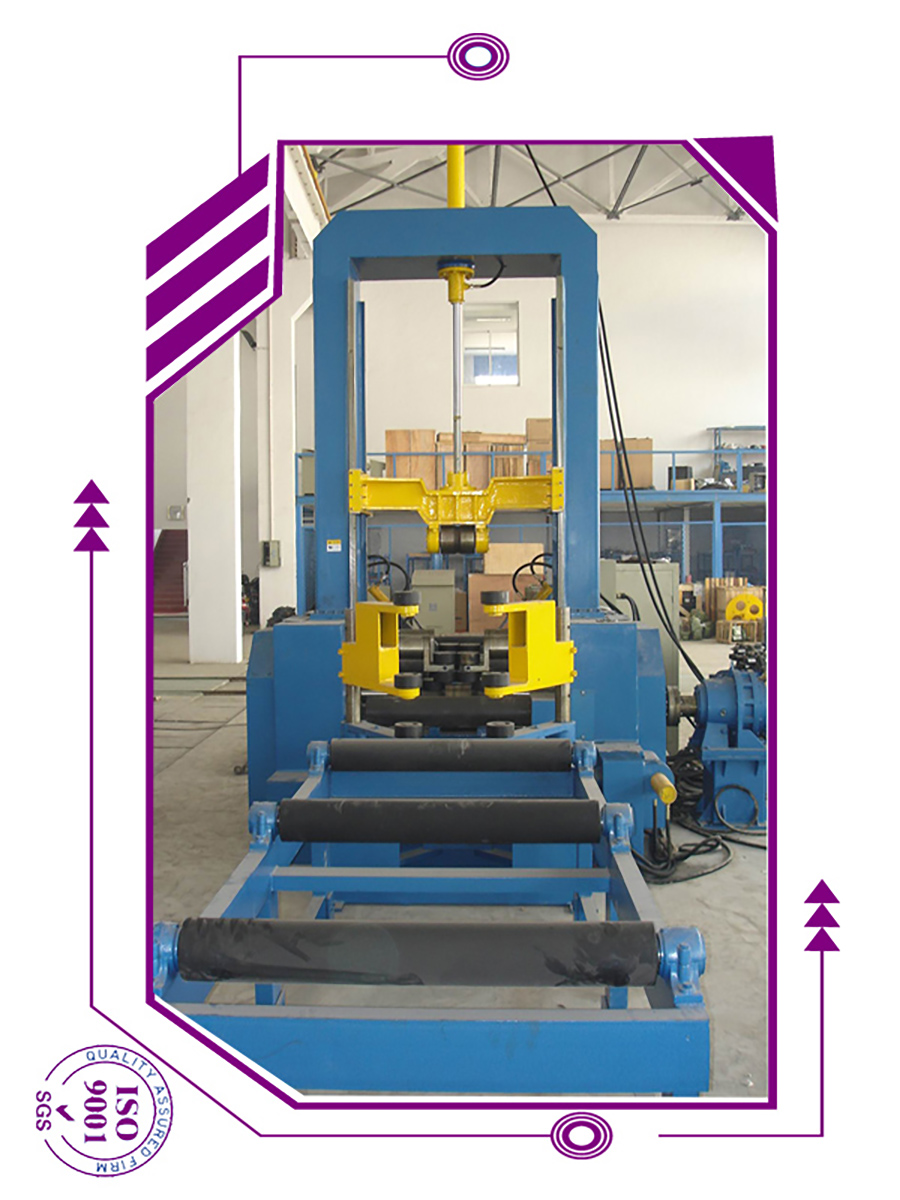

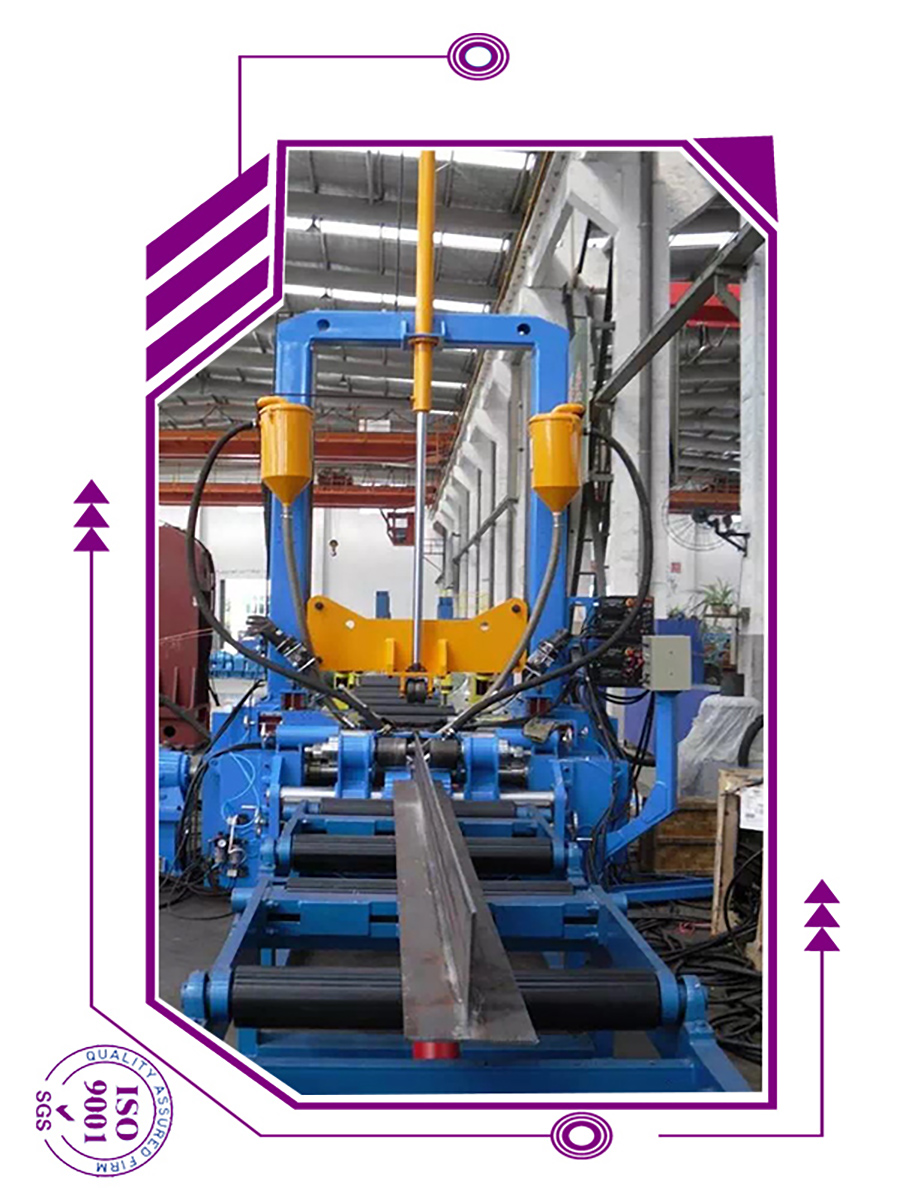

Profiled steel machining product machine Z15 is H beam assembling machine

1 Specification :

The applicable size of the H-beam produced by the welding production line:

Height range of web: 200-1500 mm

Thickness range of web: 6-32 mm

Width range of flange: 150—800 mm

Thickness range of flange: 6—40mm

Length range of beam: 15000 mm

- Main equipments and technical parameters

Z sereis H beam assembling machine

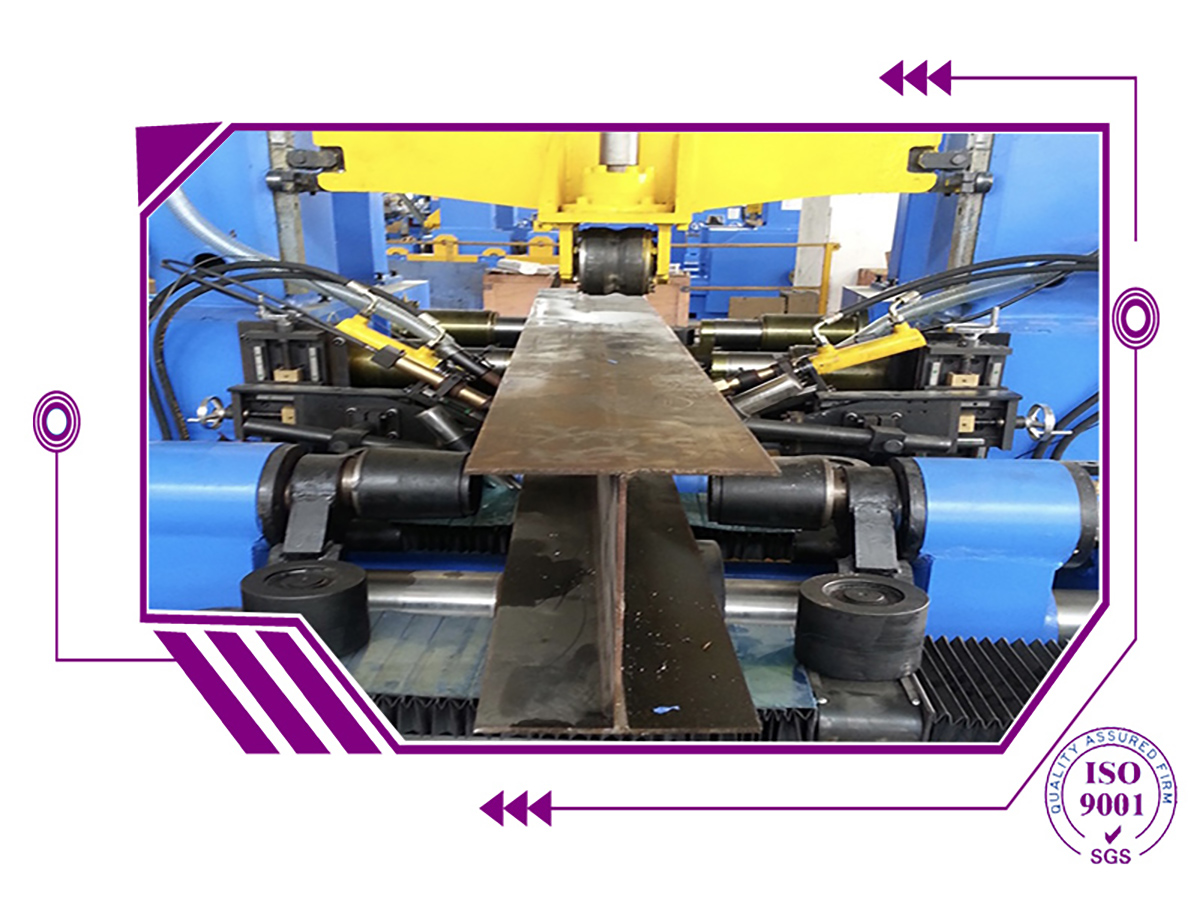

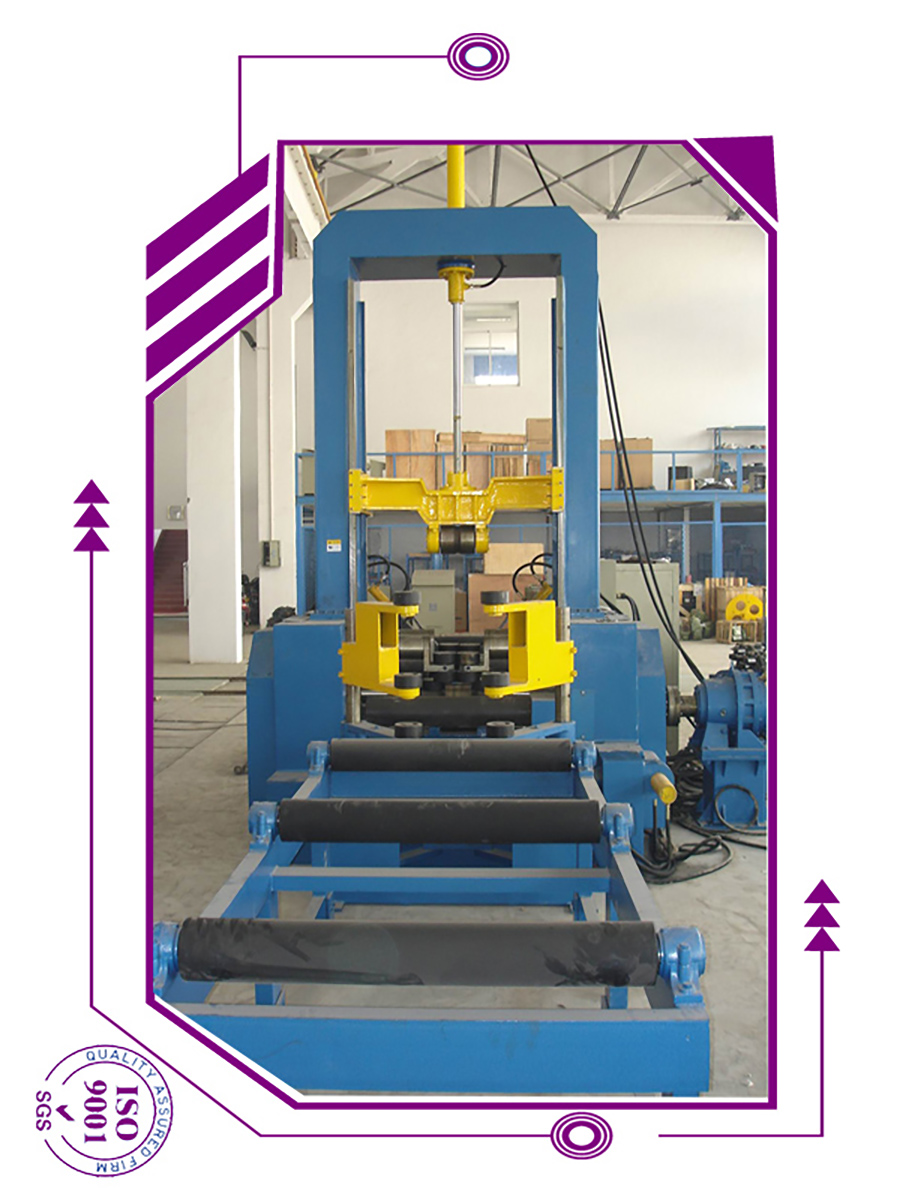

.1. Structure principle

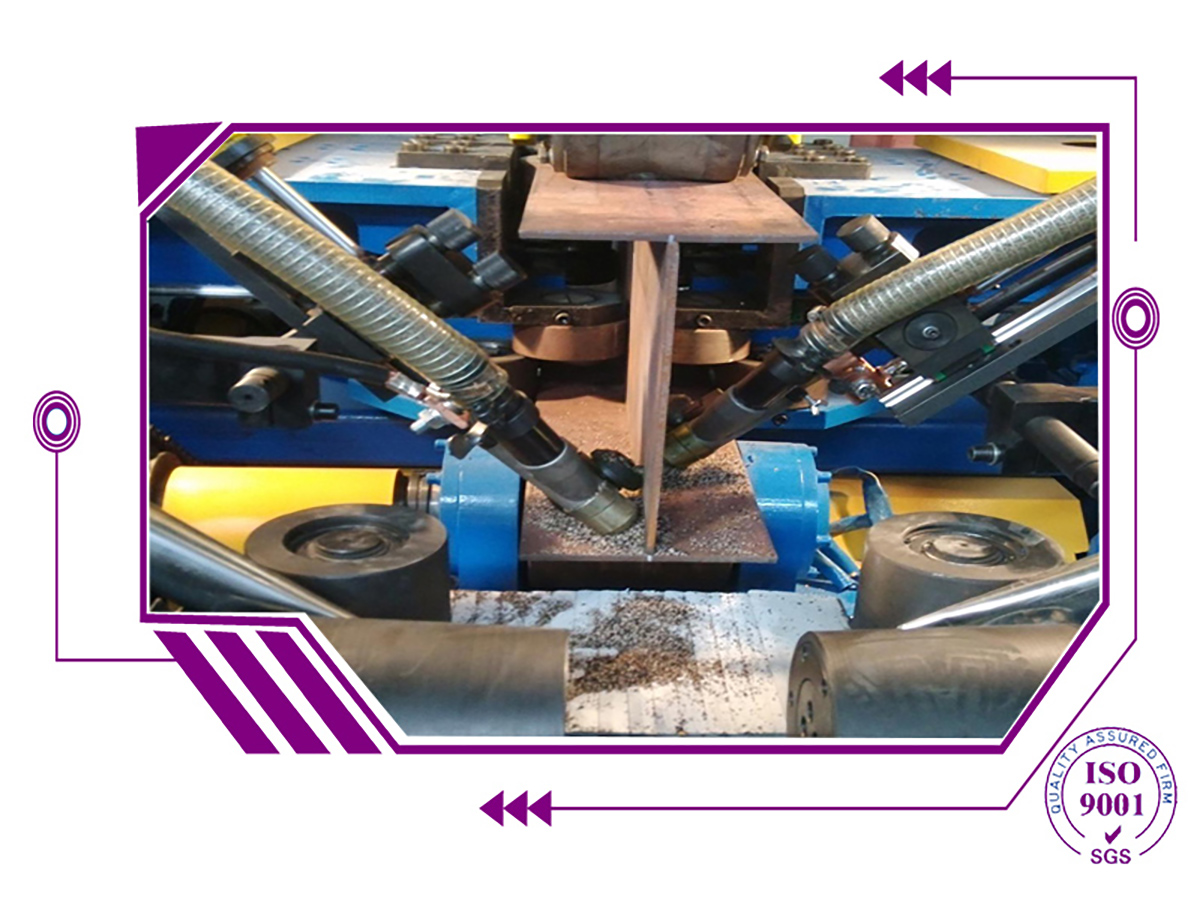

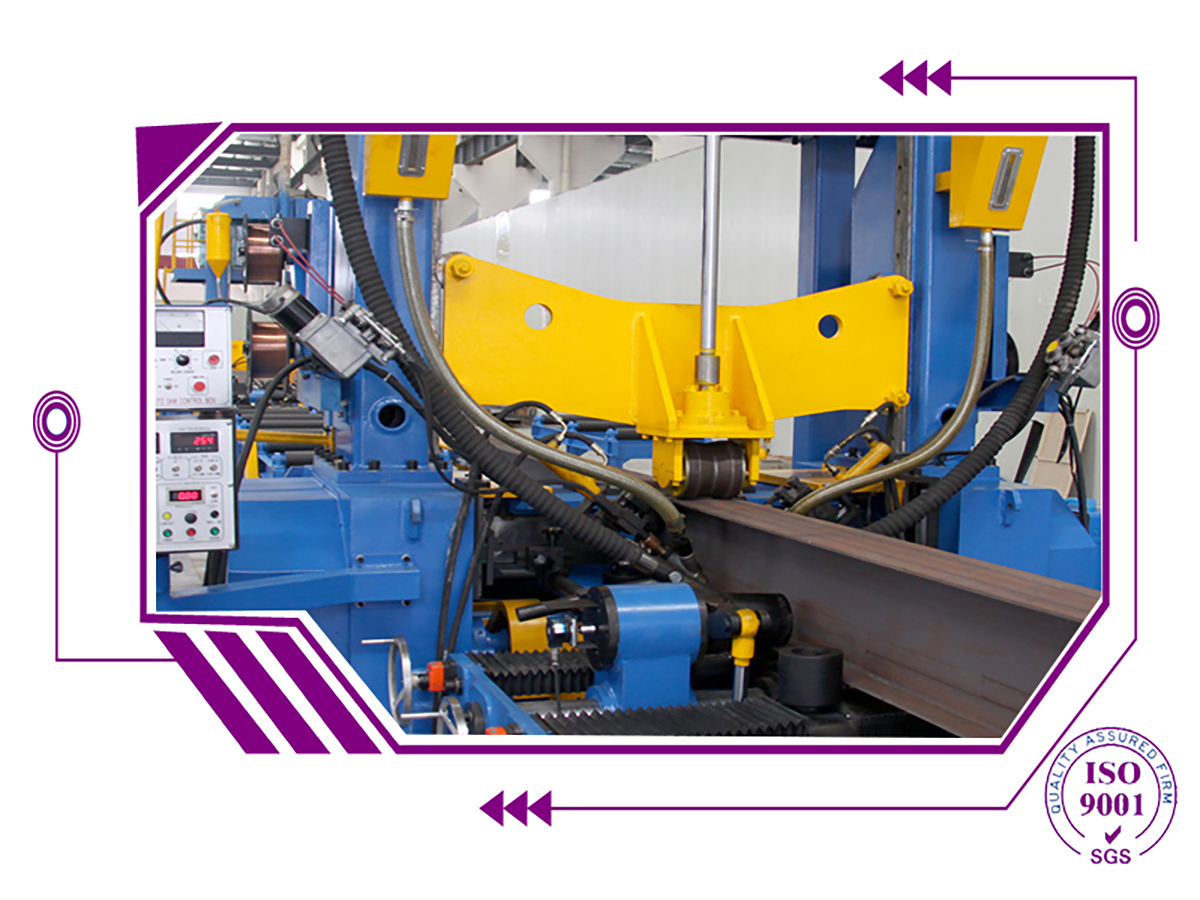

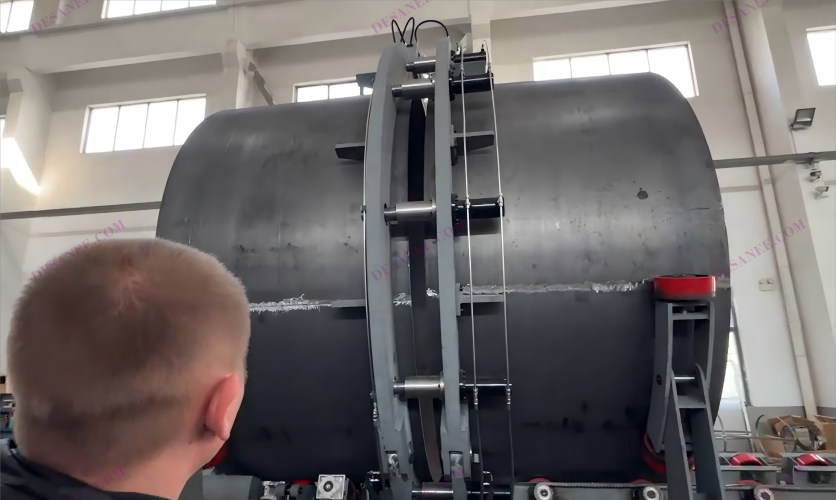

H beam assembling machine is mainly composed of frame assembly, draw bar system assembly, hydraulic system assembly, input and output roller conveyer assembly and electric controlling system . Main parts are all welding structure with high intensity and light weight, and some important parts have been treated with removing stress, not easy to deform. Main parts realize transmission through electric machine --- cycloid reducer —active roller, its line speed(assembling speed)is adjusted by AC frequency converter, can be selected in range 0.5-6M/min. Main drive roller, main compression roller are both adopted special type steel material through especial treated with good wearability and high precision. The machine is positioned and centered by hydraulic system total driving, preliminary positioned and centered by draw bar system, then centered accurately and fastened by frame assembly. The centering process of flange plates is realized through hydraulic system ---- rack-and-pinion --- chain-and-carrier wheel --- gear-and-gear --- guide screw drive. Main compression roller is up and down by hydraulic pressure, the whole process is all manipulated by electric controlling button table with merits of operating easily and positioning correctly. The speed of positioning & centering and compact force can be adjusted optionally according to the specification of formed steel. The special structure of hydraulic pressure transmission and machine synchro positioning & centering can make sure positioning of web plate correctly for any width of flange plates. Hydraulic lifting positioner in front of frame is used to align flange plates and web plate, insuring face of H-style steel flat and straight. Input and output roller conveyer is laid on input and output terminal of frame. PLC programmable controller can program according to assembling techniques of H-style steel to execute related orders. The assembling speed of H-style steel can be adjusted by changing output frequency of converter which is chosen by PLC.

.2.Technical Parameters of H beam assembling

Flange plate width 150-800mm

Flange plate thickness 6-40mm

Web height 200-1500 mm

Web thickness 6-32mm

Length of work-piece 4000-15000mm

Assembly speed 0.5-6M/min

Input conveyor: 2600mm×3 ( n -according user request)

Output conveyor: 2600mm×3 ( n- according user request)

Electrical system: A.C. inverter and PLC

General Power:9KW(2 sets of CO2 welding machine 2×12.8kW excluded)

Power Supply: AC 380V 50Hz 3-phase,

Profiled steel machining product machine Z15 (H Beam assembling machine) is used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries