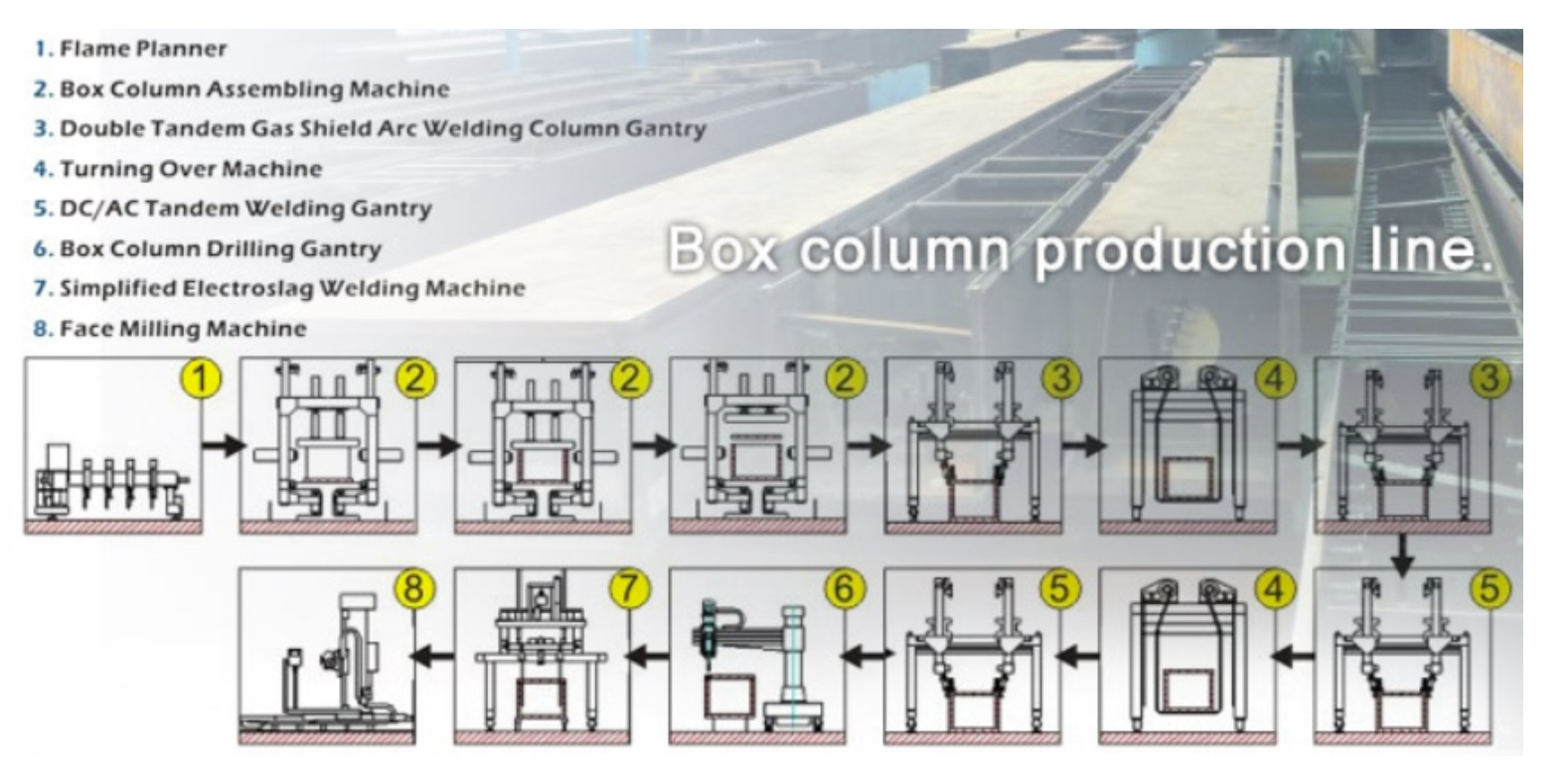

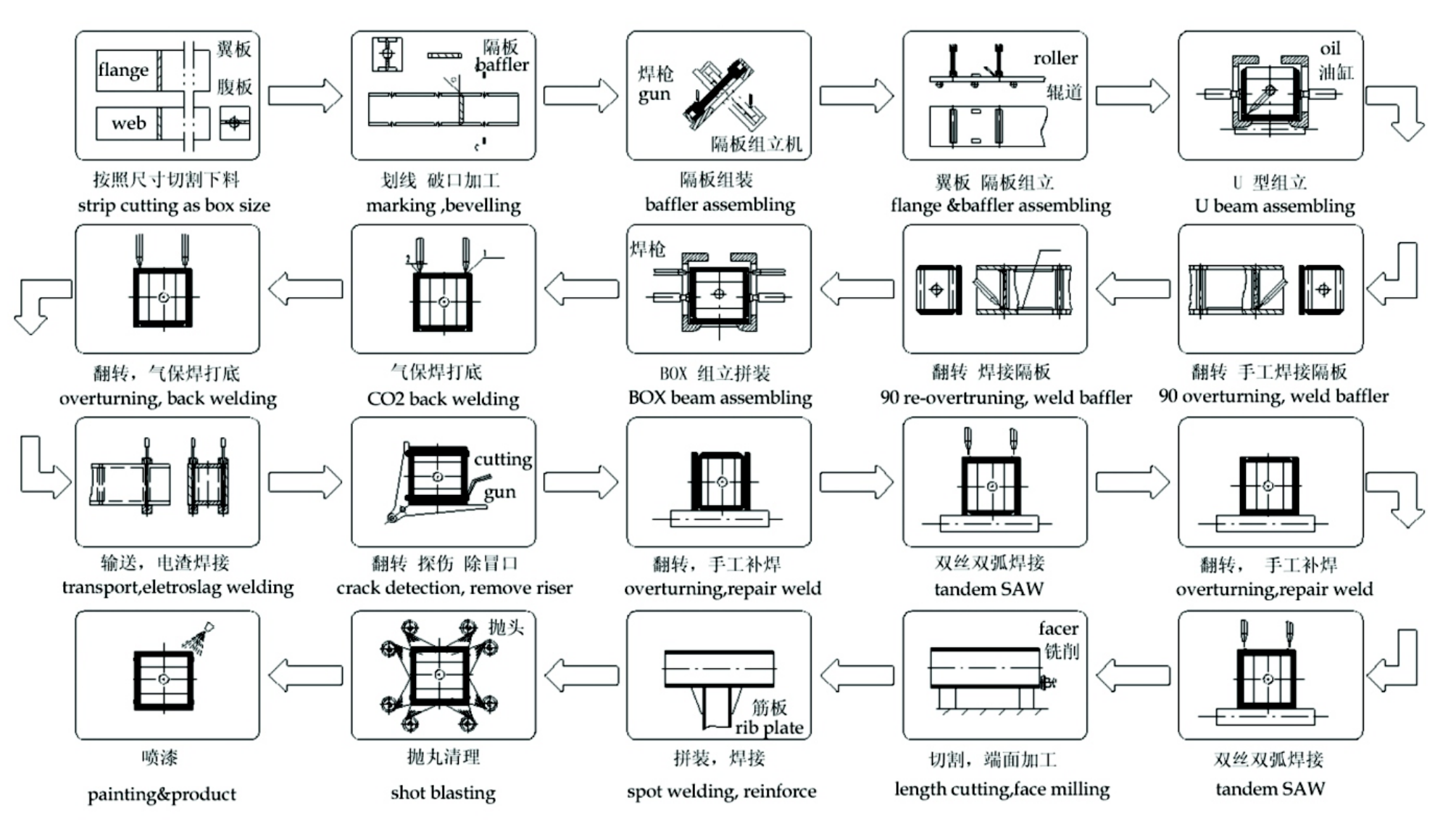

Electro-slag Welding main for Box beam build up line is widely used in bridge construction ,power station ,boiler making ,building,etc. providing with cutting machine ,groove milling , assembling baffle , assembling U-beam or box beam ,welding box beam ,chain manipulator, electro-slag welding, face milling etc.

Box beam build up line XD12 is used in petrochemical machinery, engineering machinery, wind Electro-slag Welding machine XD12

Ⅰ.CNC-CG4000A flame cutting machines

Technical data of the Machine

【See CNC page】

Ⅱ.XBJ12 Milling machine

Technical data of the Machine

【SeeXBJ12 page】

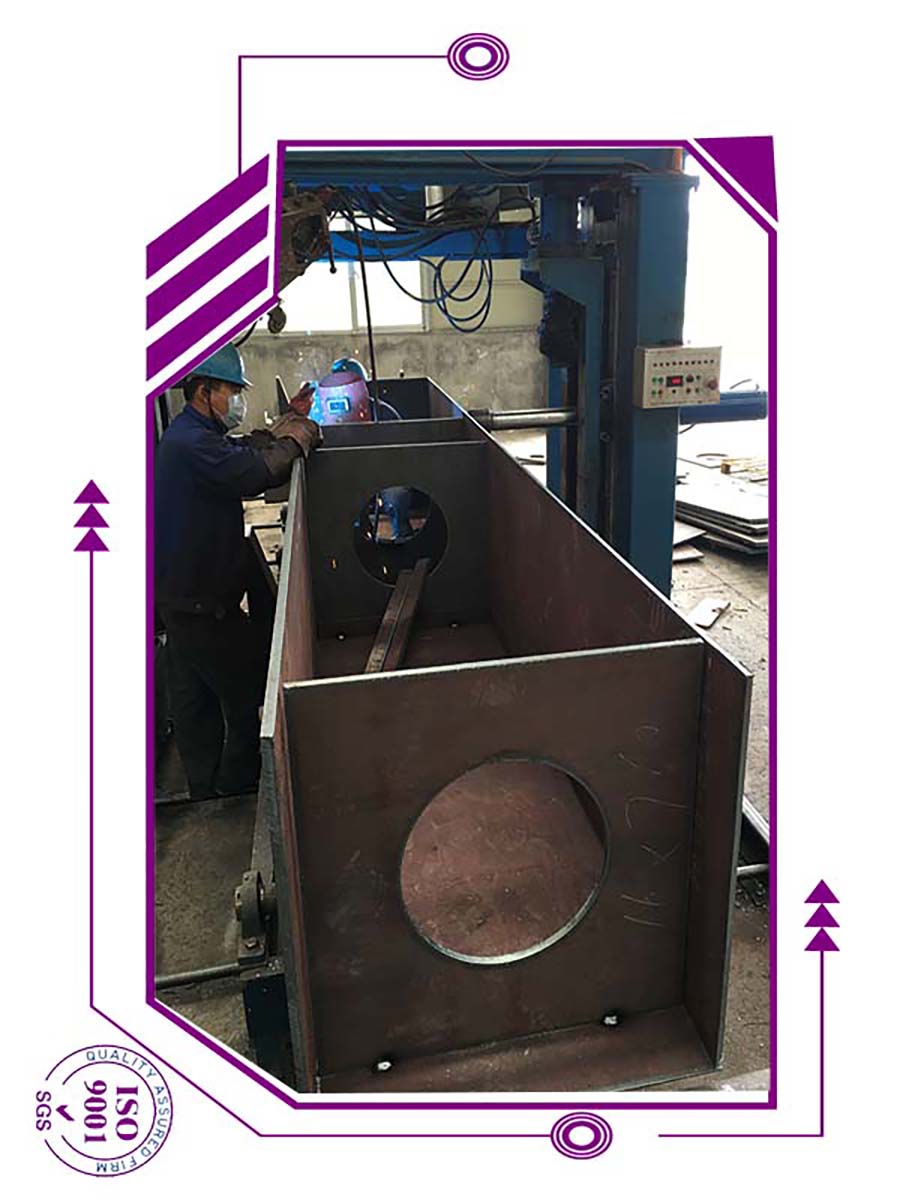

Ⅲ.GZ12 Baffle Assembly machine

1)Structure principle

This machine is the special equipment to assemble and weld baffle (strong rib) in box beam. When assembling, adopt the cylinder compacting to position, then weld them by spot. After finish to weld one face, then turn over the rotation work table for 180 degree through motor. After weld another face, turn the work table to the level, loose the cylinder and unload for working. All pneumatic elements in this machine are imported from Korea, the turnover motor is electromagnetism braking motor and driven by gear worm to ensure that the work table can stop accurately at any position with self-locking. The turnover is controlled by the foot-switch.

2)Technical parameter

- suitabledimension of workpiece: 300~1200mm

- thickness of baffle:≤80mm

- power of overturning motor: 0.75KW

- overturningspeed: 1rpm

- load capacity of working table: 1500kg

- height of rotating center: 1000m

- overturning angle of working table:±180°

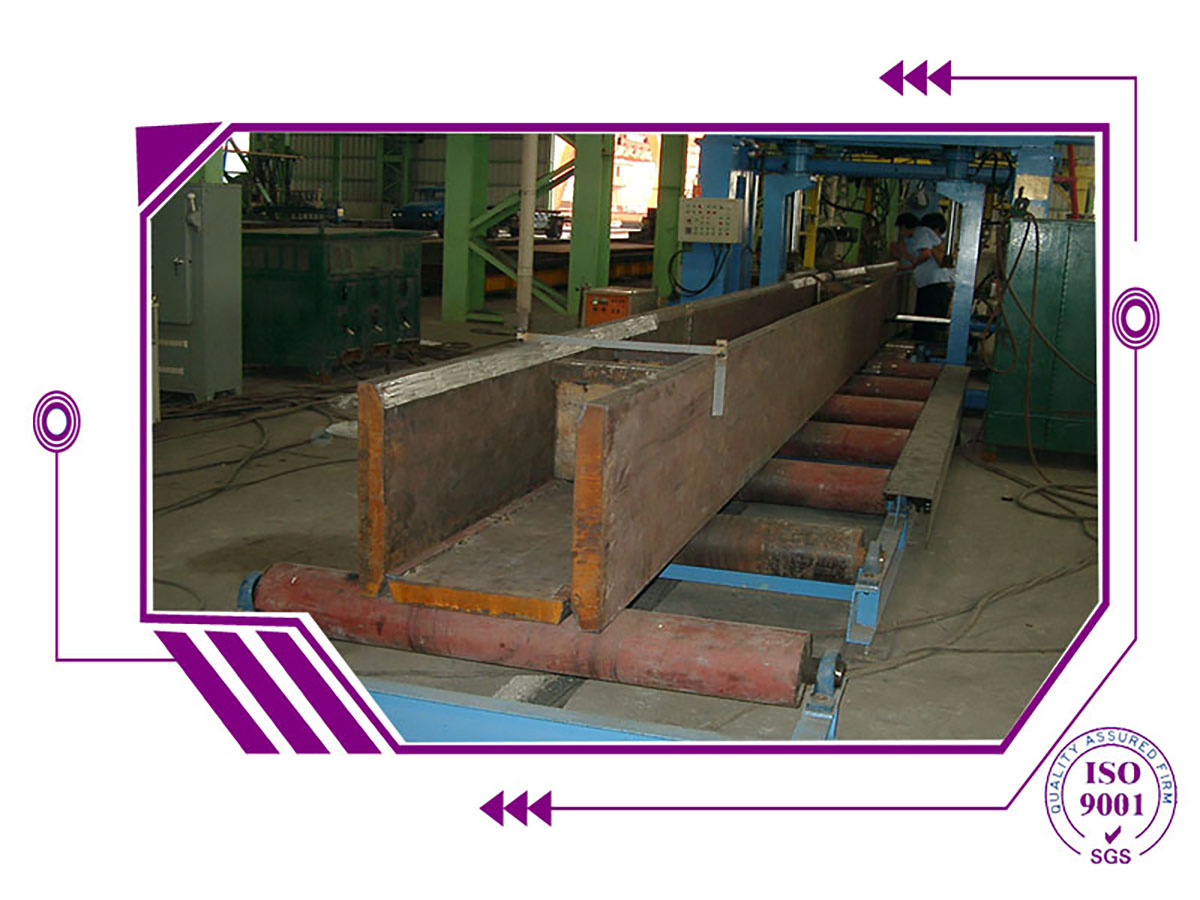

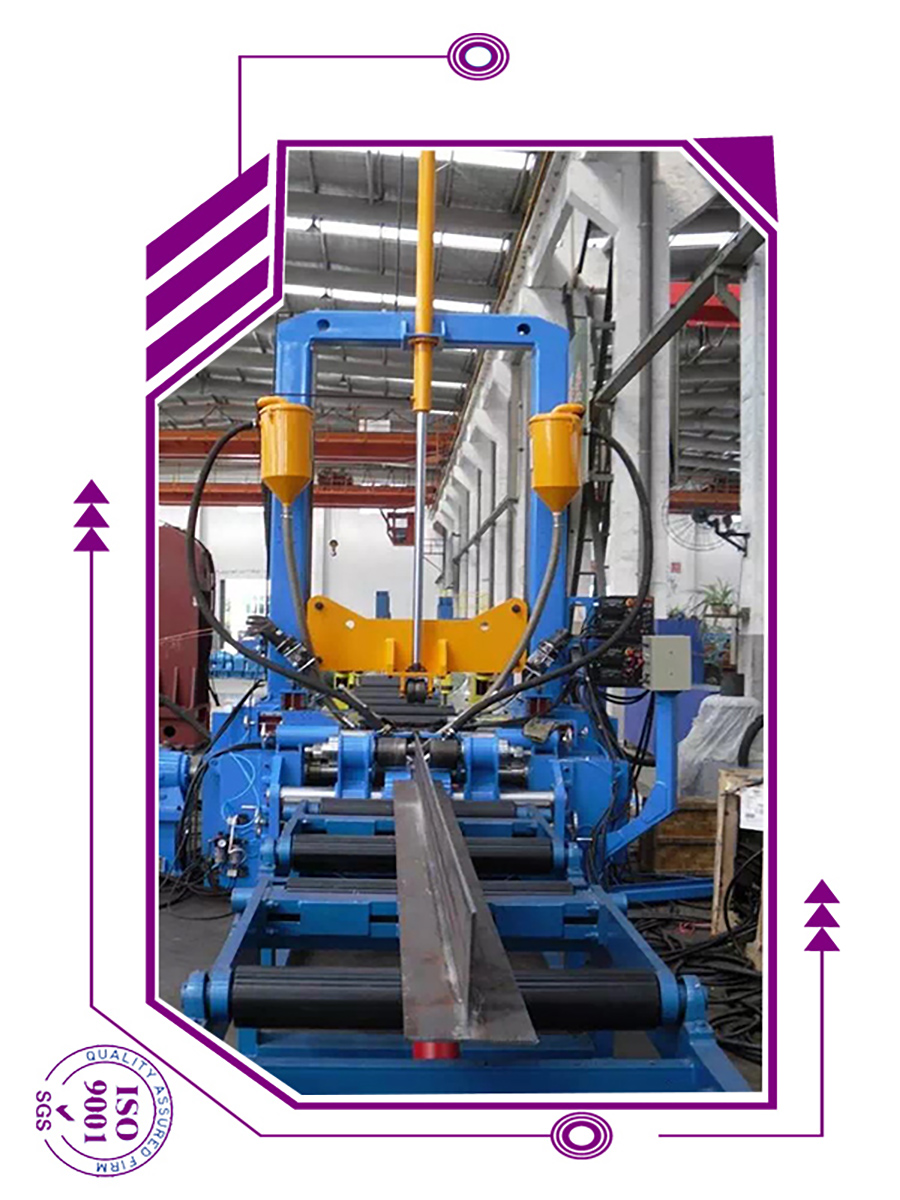

Ⅳ.UBZ12 Assembling machine

1)Structure principle

This machine is composed of gantry frame, support working table, feeding rollgang, hydraulic system and electrical control system. Gantry frame is the main part of this machine, all the tightening device installed on it. The moving of frame is driving by two motors on the below moving beam through worm gear reducer and rack reducer to bring two wheels moving on the track, the track adopted standard 38kg/m heavy track and between the two parallel track is connected by high strength drag bar which avoid the track stretch out like“八” after get counterforce of right-left oil cylinder and guaranteed the assembly quality. The rollgang turning by cycloid speed reducer driving chain, is mainly used to assembling and conveying workpiece. When assembling, put the workpiece on the platform composed by several rollgang, and the up press cylinder and side cylinder tighten the web and flange plate, then do spot welding to tightening part and through the moving of frame to weld the whole workpiece.

2)Technical parameter

- Suitable dimension of workpiece: 300~1200mm

- Length of workpiece: 4000~15000mm

- Max load capacity: 20T

- Moving speed of frame: 4m/min, 6m/min

- Pressure of hydraulic system: 14Mpa

- Max pressure of left-right oil cylinder: 15T

- Up oil cylinder: 30T

- Max stroke of left-right oil cylinder: 800mm

- Max stroke of up oil cylinder: 900mm

- Power of moving motor: 0.85/1.1KW×2

- Power of oil pump motor: 11KW

- Power of rollgang motor: 2.2Kw

- Conveying speed of rollgang: 9.3m/min

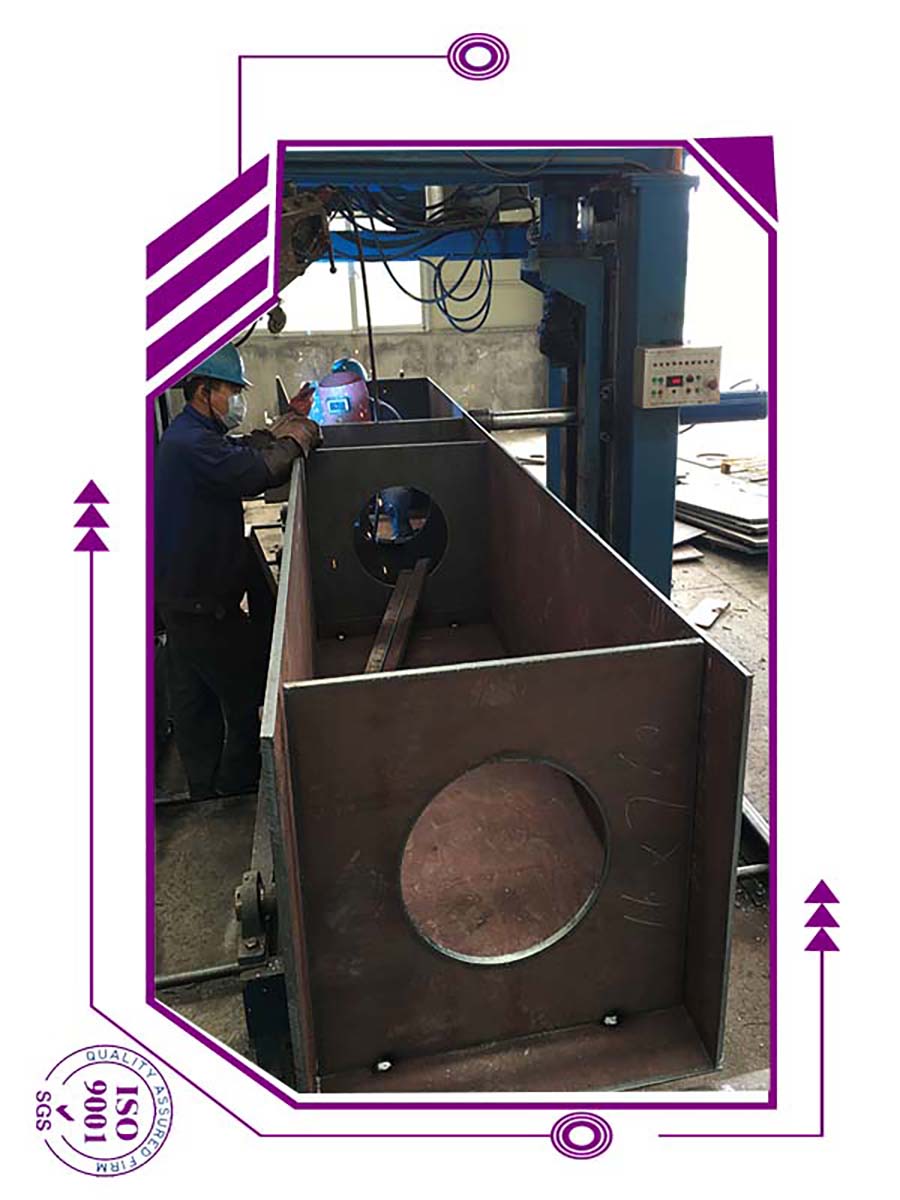

Ⅴ.XD12 Column-beam Electro-slag Welding machine

1)Structure principle for Electro-slag Welding

This machine is composed of column frame, moving cart and welding power. The column frame is to fix the Electro-slag welding machine and guarantee the welding head aim at the welding hole. Below part of frame is moving cart which driving by AC motor through speed reducer. In order to weld the baffle more firm to the inside of box beam, when assembly the baffle there’s left a certain clearance between baffle and box beam. The box beam feed by rollgang to the vertical frame and then the vertical electro-slag welder weld the clearance left. The column frame can move in the length direction.

Power source: American Lincoln DC-600×2

2)Technical parameter

- Gauge: 1000mm

- Moving speed: 6m/min

- Power of moving motor: 0.55kw

- Suitable dimension of workpiece: 300~1200mm

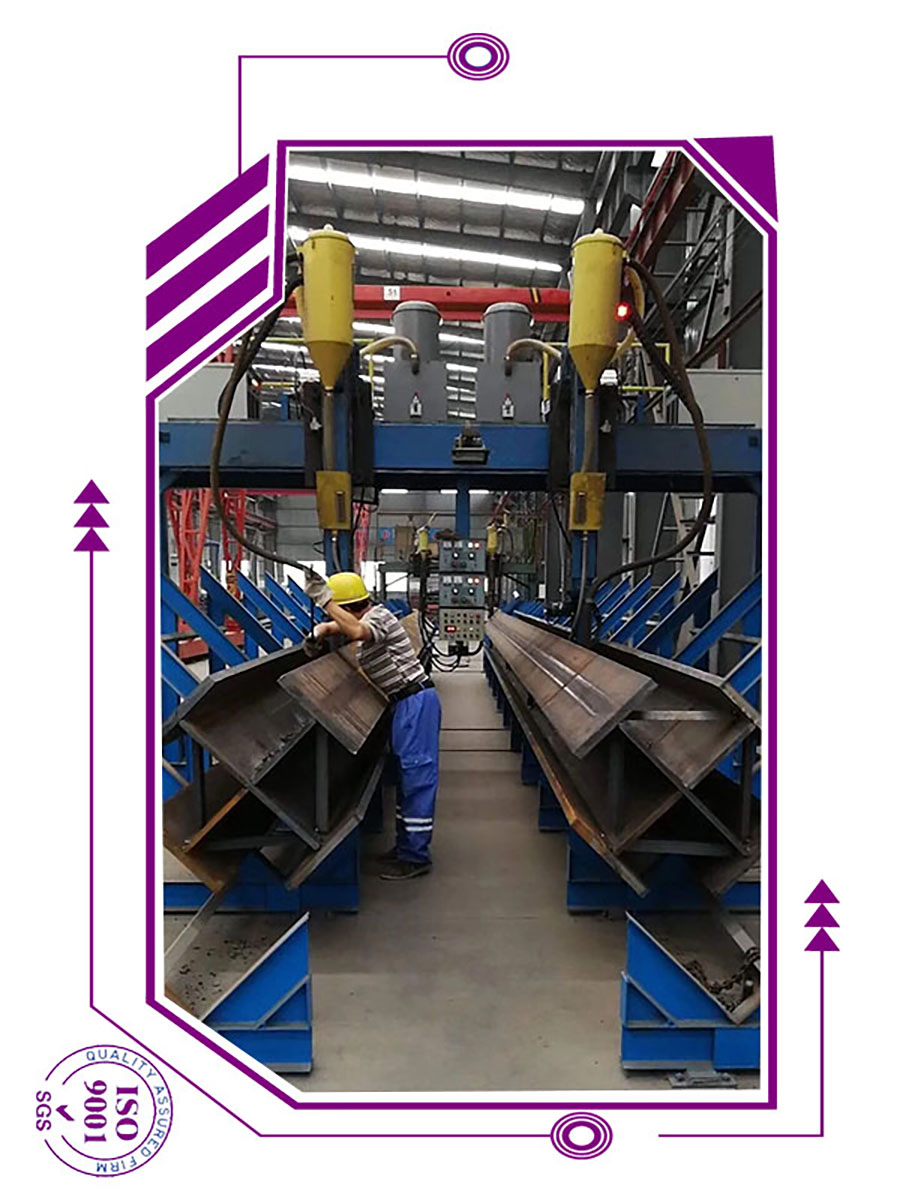

Ⅵ.LHF Column-beam S.A.W Welding machine

1)Structure pinciple

This machine is composed of gantry, welding arm , seam machine tracker, flux auto recovering and feeding system, electric box part and Lincoln welding system etc.

2)Technical parameter

- Suitable dimension of workpiece: 300~1200mm

- Length of track: 18000mm

- Gauge: 4000mm

- Total power of frame: 3Kw

- Power of welding flux recycle machine: 2×3Kw

- Gas pressure: 0.4~0.8Mpa

- Welding speed: 0.15-1.5m/min

- Returning speed: 2.4m/min

Welding power: 2 sets of submerged arc welder DC-1000A and 2 sets of AC1200

Ⅶ.DX1212 Face Milling machine(Include hydraulic support table)

1)Structure principle

Model DX1212 face miller is composed of horizontal driving, horizontal sliding table, vertical driving, vertical rotating sliding table and electrical control system.

1.1Horizontal driving

This is composed of table, horizontal feed motor, speed reducer, horizontal driving screw mandrel and screw nut. The table adopted welding structure and through annealing, and then through rough process and precision process. Its characteristics: high strength, little deformation, reasonable structure and good technology; one good load capacity rectangle track and one precision V-type track.

Horizontal driving mechanism is composed of feed box, trapezoidal feed screw driving and support frame; feed box adopted double speed motor, each used for horizontal feed and horizontal quick forward and backward during milling process; feed screw driving use drive and idle screw nut to guarantee the precision of horizontal driving; the two screw nuts fixed on the screw nut base frame at the same time, the screw nut base frame is connected with horizontal sliding table which drive the sliding table moving forward and backward along the track.

1.2 Horizontal sliding table

It is mainly composed of sliding table and track guard plate; the sliding table is casting; vertical mechanism such as column fixed on the sliding table.

The track guard device adopted telescopic cover superposition has good leak tightness and long service life. There’s sight hole on the guard plate, so you can see the lubrication station and cleanliness and also can add oil to track; there’s cover plate on the sight hole, so you can cover the sight hole after finished.

1.3 Vertical driving

It is composed of column, driving motor, speed reducer, trapezoidal screw mandrel and screw nut; the column is welding structure member and through welding, stress relief, mechanical milling process; it has advantages of stability structure and high mechanical strength.

Vertical driving mechanism is composed of vertical driving motor, speed reducer, and screw mandrel and nut; screw driving used drive and idle screw nut to guarantee the driving precision.

1.4 Vertical rotating sliding table

It is composed of elevating carriage, rotating worm gear and standard milling head;the elevating carriage is made of gray cast-iron and match with the vertical track on the column, it has advantages of good wearable and shock proof; rotating worm gear is made of nodular cast iron, it has advantages of good wearable and high strength, and drive the milling head rotating 0-450 on the elevating carriage so that can enlarge the process range; the milling head has advantages of reasonable structure, reliable performance, large speed range( the speed of main shaft is 125-630rpm), good rigidity, low noise, high efficiency and convenient operation, and reduce users’ difficulty on choosing tools.

1.5 Electrical control system

It is composed of electrical control box and operation system.

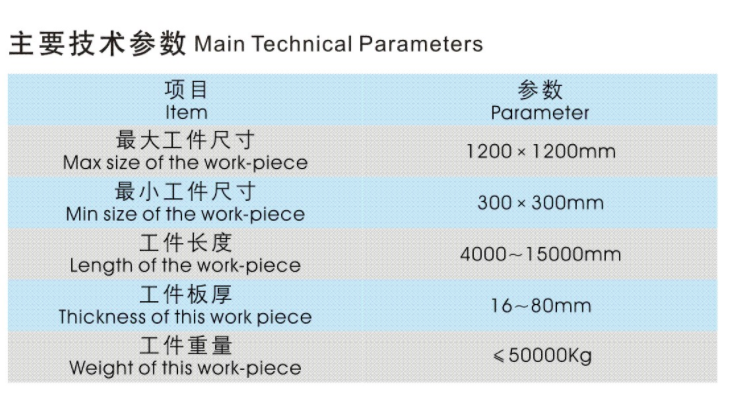

2)Technical parameter

- Power of milling motor: P=5.5Kw; 1440rpm

- Apply in workpiece: 1200×1500mm

- Moving speed of workpiece forward: V=54.8~548mm/min

- Quick return speed of sliding table: V=822mm/min

- Horizontal driving motor power: 3KW/4KW (turning speed is 960/1500rpm)

- Vertical driving motor power: 1.5KW (turning speed is 1400rpm)

- Milling head

turning speed of main shaft: 125-630rpm

stretch out length of main shaft: 63mm

- Diameter of milling cutter: 200-320mm

- Vertical forward speed: 53-530mm/min

- Quick elevating speed of milling head: 530mm/min

Ⅷ.YFL1220 90 degrees hydraulic overturning machine

1)structure principle

This machine is mainly used to overturn T type steel or combined H type steel so as to input it to next process for welding. It adopts hydraulic overturning type, use 2 cylinders to drive 2 L-type frame to synchronize revolving 90 degrees, and T type or H type steel over 90 degrees accordingly, which can convenient for welding and conveying.

2)Main technical parameter:

Suitable for weight of work-piece: ≦20T

Moving speed: 5m/min

Moving motor power: 1.5KW

Overturning cylinder diameter: φ125mm

Max pressure of hydraulic system: 16Mpa

Ⅸ.YF1220 Transverse overturning machine

1)Structure principle

This machine is used to overturning the steel when finished welding one side, driving by two hydraulic oil cylinder. so as to input it to next process for welding. It adopts hydraulic overturning type, use 2 cylinders to drive 2 L-type frame to synchronize revolving 180 degrees, and T type or H type steel over 180 degrees accordingly, which can convenient for welding and conveying.

2)Technical parameter

- Weight of work-piece: ≤20T/group

- Power running speed reduce motor: 1.5KW

- Running speed: 5m/min

- Overturning cylinder diameter: φ125mm

- System pressure: 16Mpa

- Center distance of tracks: 700mm

Ⅹ.Roller conveyer 154m

Technical parameter

Roller diameter: φ200mm

Thickness of roll: 14mm

Length of roll: 1000mm

Weight of workpiece: ≤20T