Hardfacing machine for Steel and General Maintenance Workshops

H-Frame hardfacing machine machine is a flexible, cost-effective weld surfacing machine with a quick return on investment. It can be used in many applications: flat welding, roller welding, spiral welding and welding with several welding heads at the same time. It is available in various sizes, allowing it to be customised to the needs of the workshop.

Desan AUTO control system is installed for all of the H-Frame machines, either in the Touch or Pendant configuration. The control system is designed for fast and easy weld set-up of different components, while maintaining precise control of the whole welding process.

H ardfacing machine Characteristics

- D3 touch system

- Five easily adaptable options

- Multiple weld pattern: oscillating beads, stringer beads, square waves, chevron shape and spiral welding

hardfacing machine Benefits

- Repeatable programming

- High quality weld deposits

- High productivity in manufacturing

- Adaptable to any workshop size

hardfacing machine Possible configurations

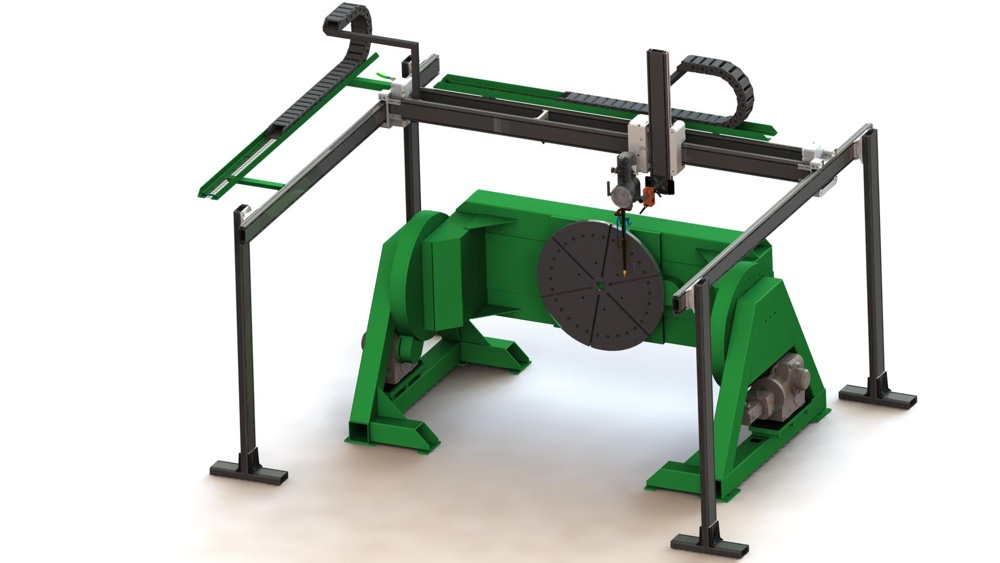

- H Frame on top of manipulator

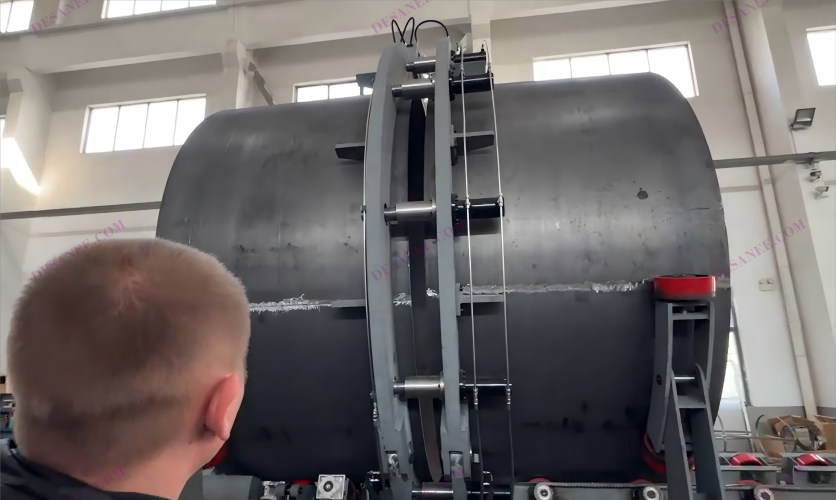

- Vertical mill rollers for Cement and Coal Industry

- Roller welding in general

- Internal pipe cladding

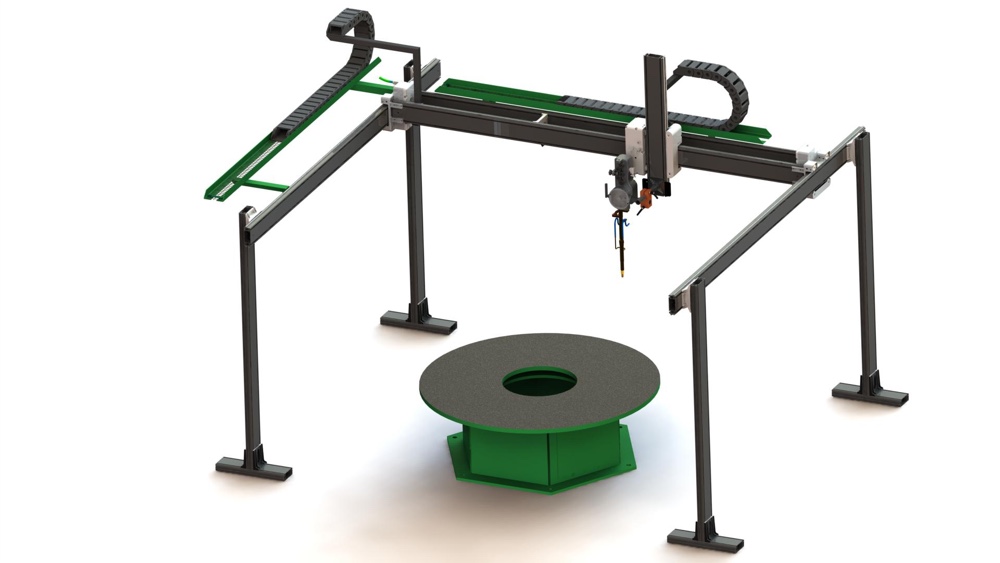

- H Frame on top of a rotating table

- Valves

- H Frame on top of lathe

- Roller welding

- Screw conveyor welding

- H Frame on top of a table

- Flat welding

- H Frame multiple welding stations

- Flat welding

hardfacing machine control system is designed for fast and easy weld set-up of different components, while maintaining precise control of the whole welding process. and use HMI touch system and PLC via ethercat and serve motor ,and also DATA upload Cloud SQL

|

|

|

|

|

|

|

|