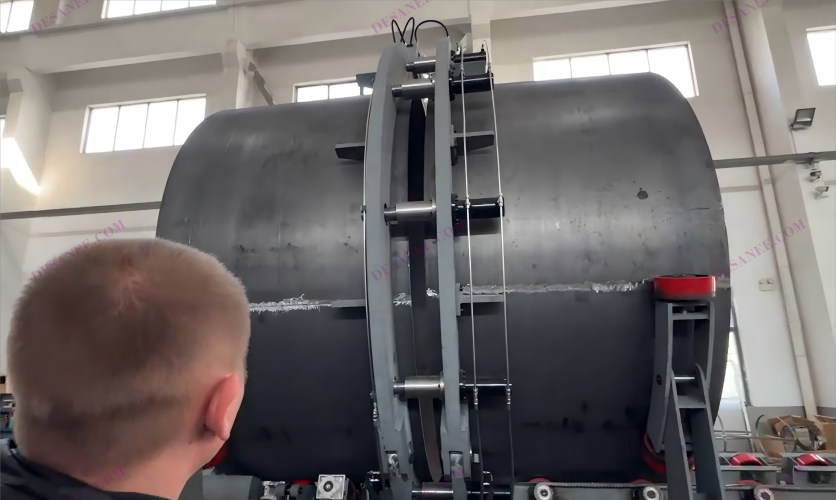

Hardfacing welding Machine DH50

1.Summarize:

This machine mainly useds for the hot roller or other cylinderses the surface of repair welding after wear away, welding method is the automatic welding of submerge arc (SAW or FCAW) .The work piece is tighted by four claw chuck , this machine contain operation convenience, the structure is simple and adjusts quick etc. advantage, is the essential equipments of the house of professional factory of hardfacing welding.

2. Function characteristics:

Dh50 type machine is a main process equipment used to hardfacing welding hot roller ,its framework is cantilever , on it fixed traverse rail and drag board ,and its travel speed adopted SPWM AC or DC control way, which is widespread adoption in automation realm currently. Its function stability credibility, the usage convenience, its speed as 2-230 mm/ min, can carry on regulate according to the request of the welding within the allow range ;We can provide with single wire single arc arc welding head according to customers requirement , welding positioner is used to placed the work piece in the best position for welding. at the same time we can design and customize various type of special positioner according to the technological requirement and different work piece given by the customer.

Welding equipments adoption of this machine compares ZXG-1000 welding power supply, the machine head and the control box adoption MA-1000 have the credibility high, weld stable etc. characteristic.

Hardfacing welding Machine DH50 (plasma welding) is used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

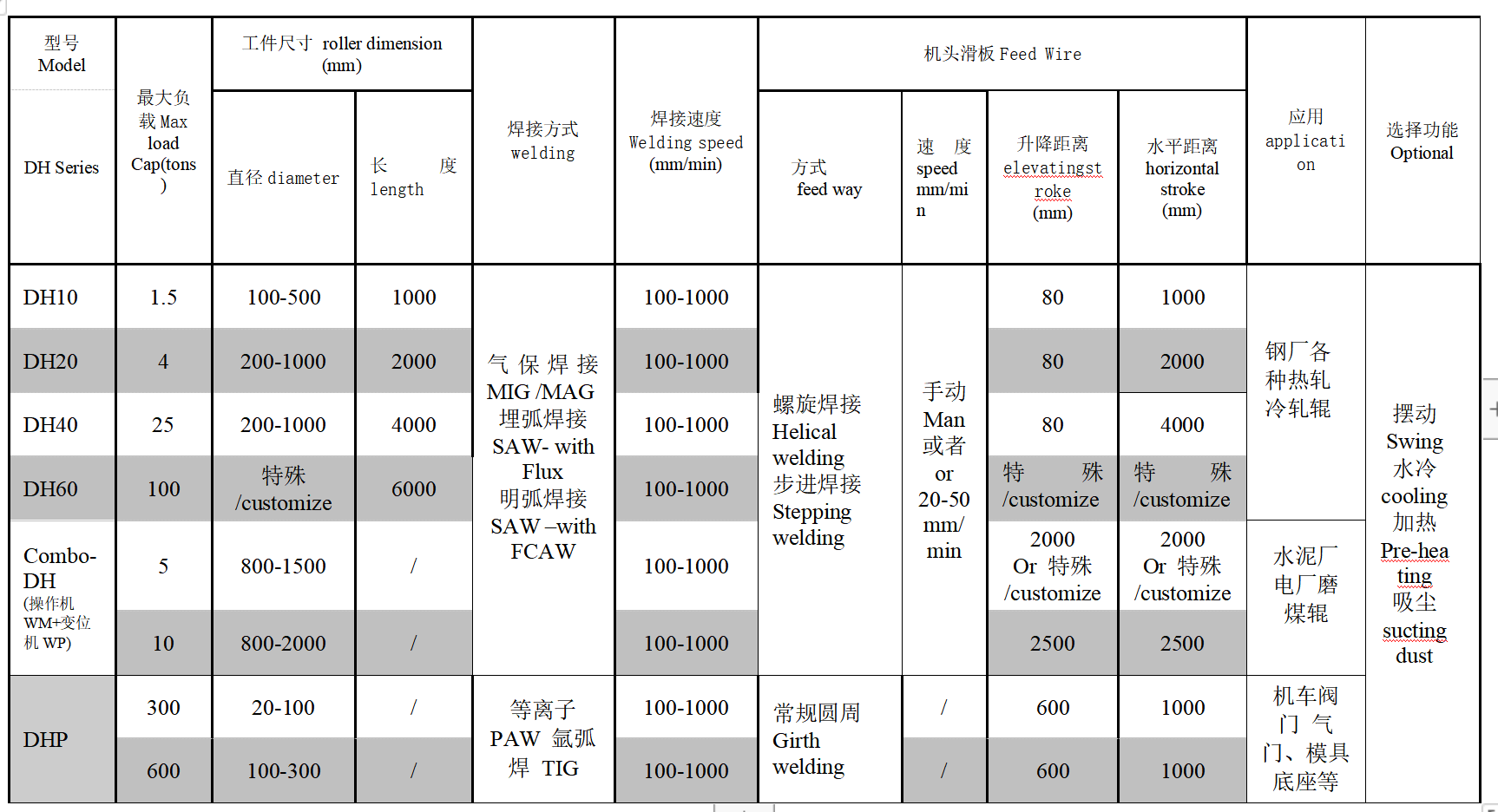

3.Technique parameter:

Apply max diameter: Φ1000 mm

Apply length: 5000 mm

Apply weight: 6 T

The turn-over center high: 800mm

Principal axis power: 0.75 KW

principal axis turning speed: 0.1-1rpm

Horizontal motor power: 40W

Horizontal speed: 2--30 mm/ min

Welding current : 200-1000A

Apply wire diameter : Φ2.4.0-4.0 mm

4.The key installation

Welding system:DC-1000 made in USA

5.Provide range:

a, Main machine : including cantilever, crossbeam, drag board, head adjust framework .

b, Down framework : including two rotator ,

c, Electricity control system

d, Welding system :

including: DC-1000 power supply, NA-3S box, welding head ,