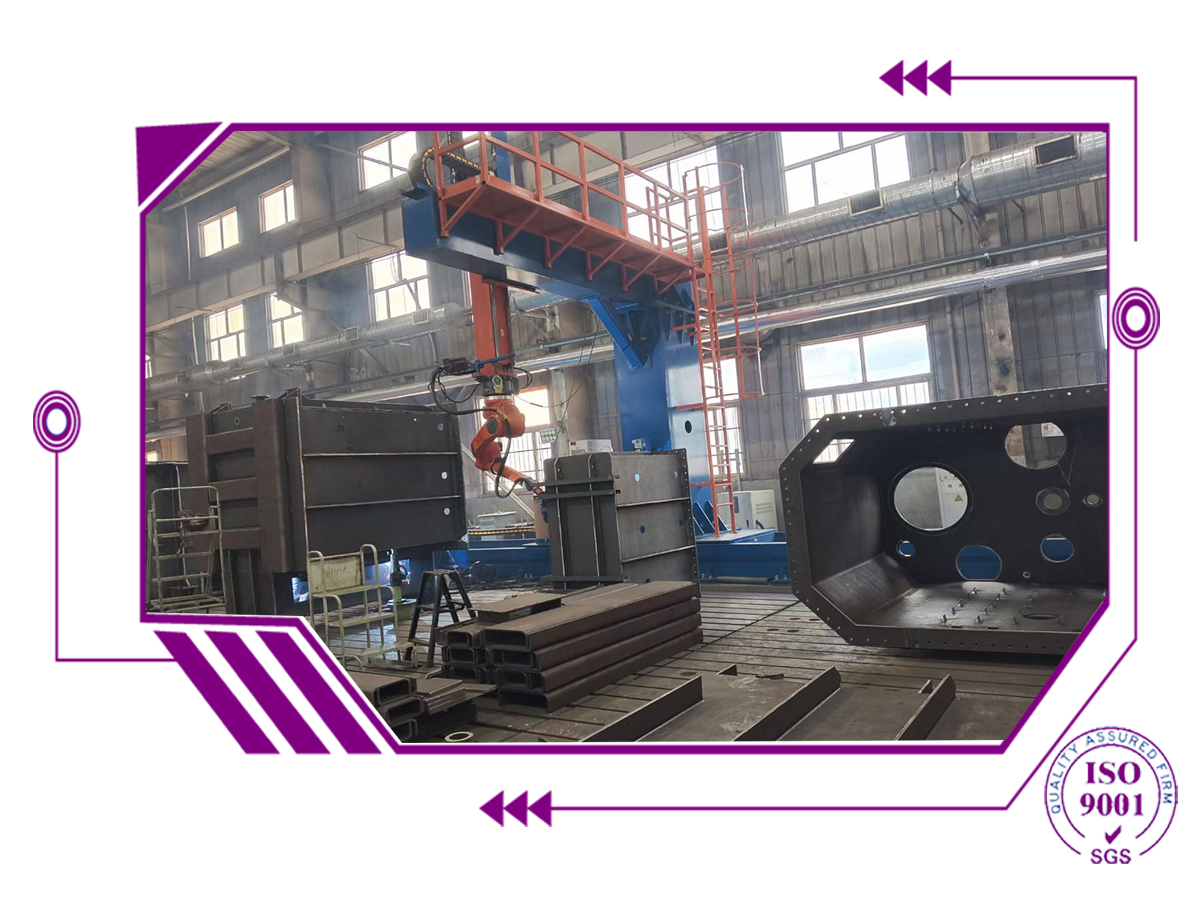

Robot Welding Positioner Double axis P type (SETS)

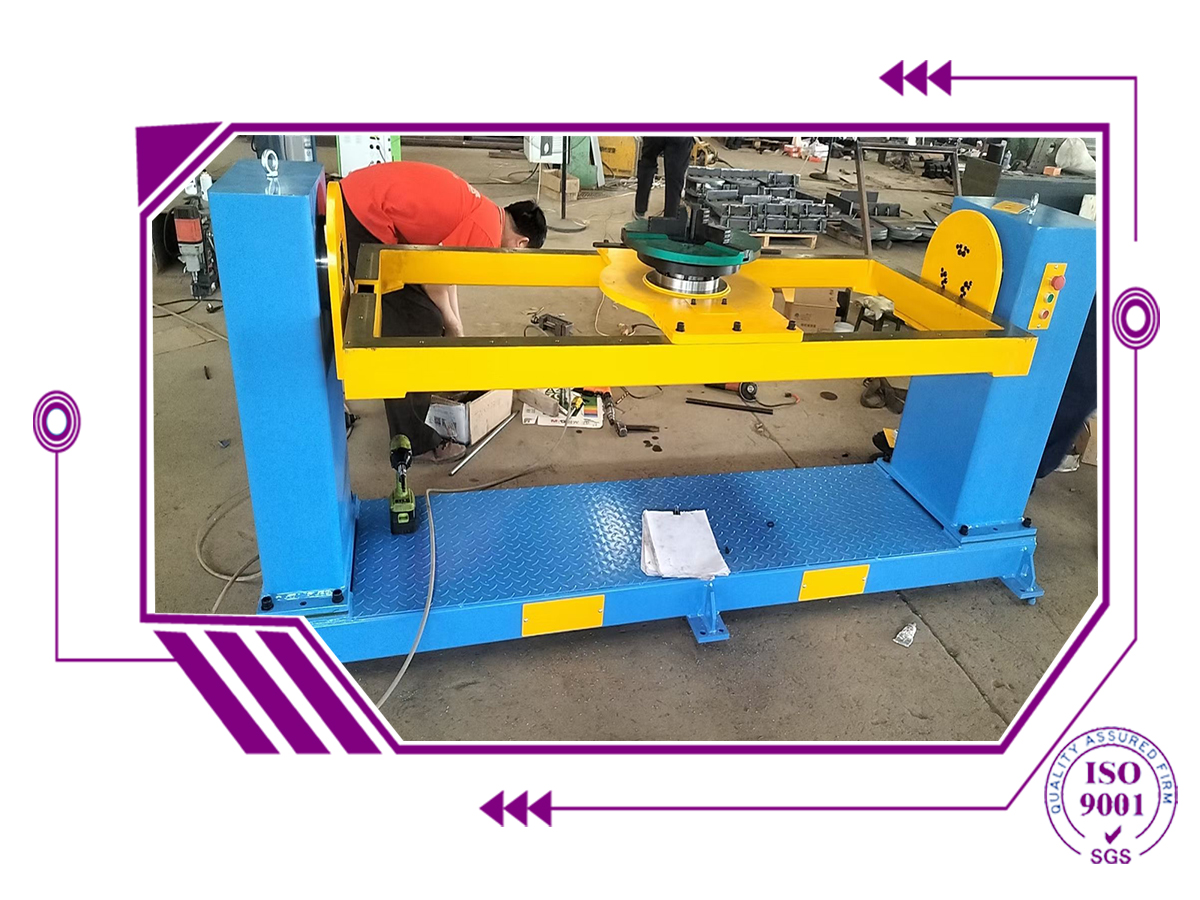

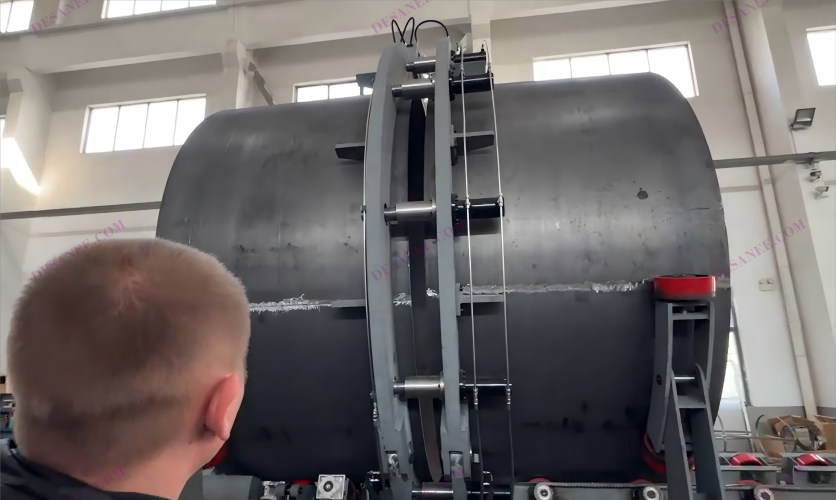

The welding positioner has novel exterior design, compact structure, stable operation, convenient operation, low noise and low energy consumption. The flip box is equipped with a spring-loaded conductive device with a maximum conductivity of 500A. The negative wire of the welding machine is connected to the equipment, effectively avoiding the entanglement of the welding cable.

Robot Welding Positioner Double axis P type (SETS) (robot welding) is used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

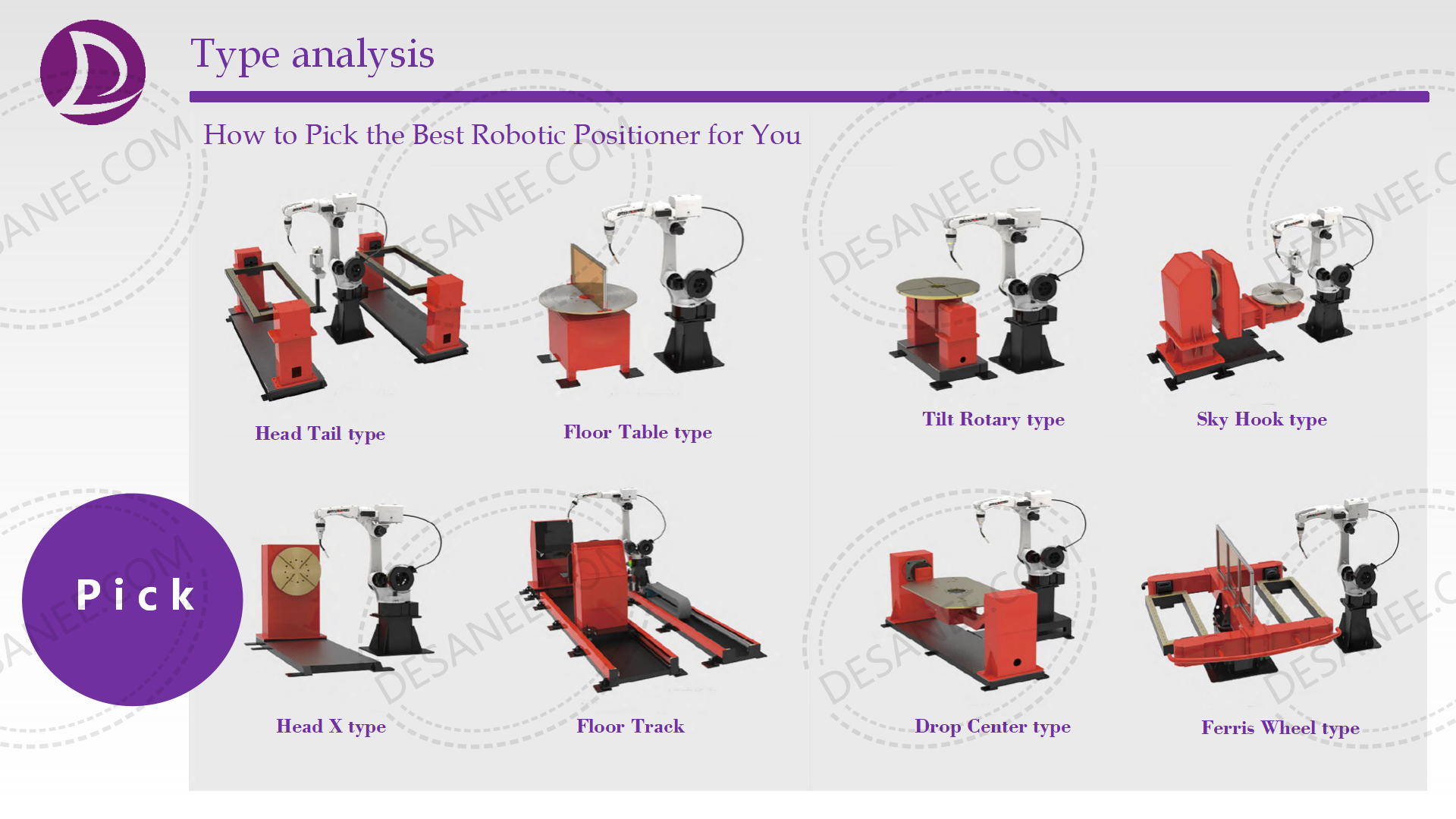

Double axis P type welding positioner for robot rotary

The two-seat welding positioner is suitable for welding various shafts, discs, cylinders, pipe fittings, school chairs, steel pipe furniture and other rotating workpieces. for Robot Welding

The first and second axes of the two-axis positioner can move independently or in linkage, which is suitable for workpieces with complex welding paths.

The double-axis P-type welding is changed to a double-seat structure for the body. The overall stability of the equipment is good, and it can be fixed on the foundation or on the iron plate.

Performance characteristic:

•Stable and smooth action,wear resistant and durable.

•The vertical axis adopted servo moter with accuracy to 0.1mm,high speed,heavyload,to increase production efficiency.Handheld control system adopts conversational operation which can be selected multiple languages view powerful function,and supports many groups of extension input/output to improve the automatic manufacture.

•Self-diagnostic system continually monitors input/output status and stores recent error message records.

•Robot Welding can inspect the air presure automatically,it will alarm when its not safe.

•Robot Welding has the CE standard

High Efficiency:

Adopting the domestic advanced RC control system, the robot can optimize the acceleration according to actual load and shorten the operation cycle to the greatest extent.

High Reliability:

Through the internal service information system, the robot monitors the motion and load, and optimizes the services requirements to ensure to continue working longer.

Outstanding Security:

Advanced motion control and collision detection option greatly reduce the damage risk of tool and work piece.

Large Working Area:

The vertical multi-joint structure allows the robot to bear up to 20kg payload and 1595mm reach distance.

Stable and High-precision performance:

The position repeatability is 0.05 mm, The robot won't be affected in long-time working state, which ensures the stability of product quality.

Professional, Sincere and High-Quality Service:

All over the country provide efficient technical service, removing your worries for the future.