Reliability and user-friendliness for high performance, top-quality roller cladding

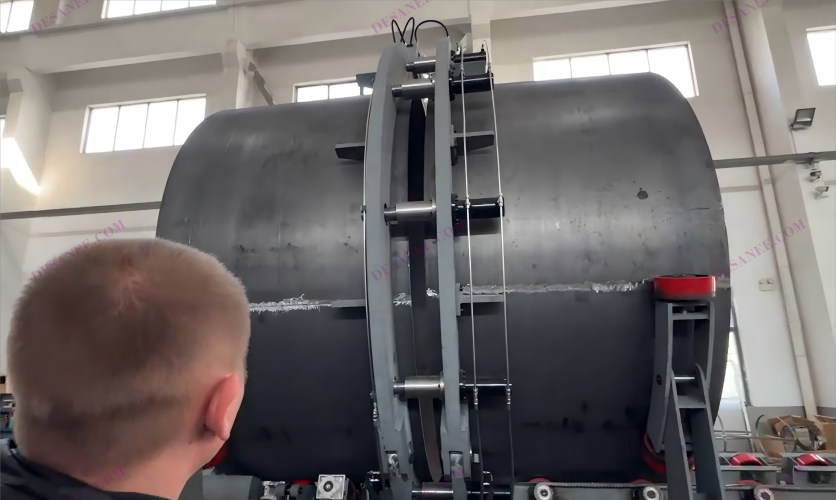

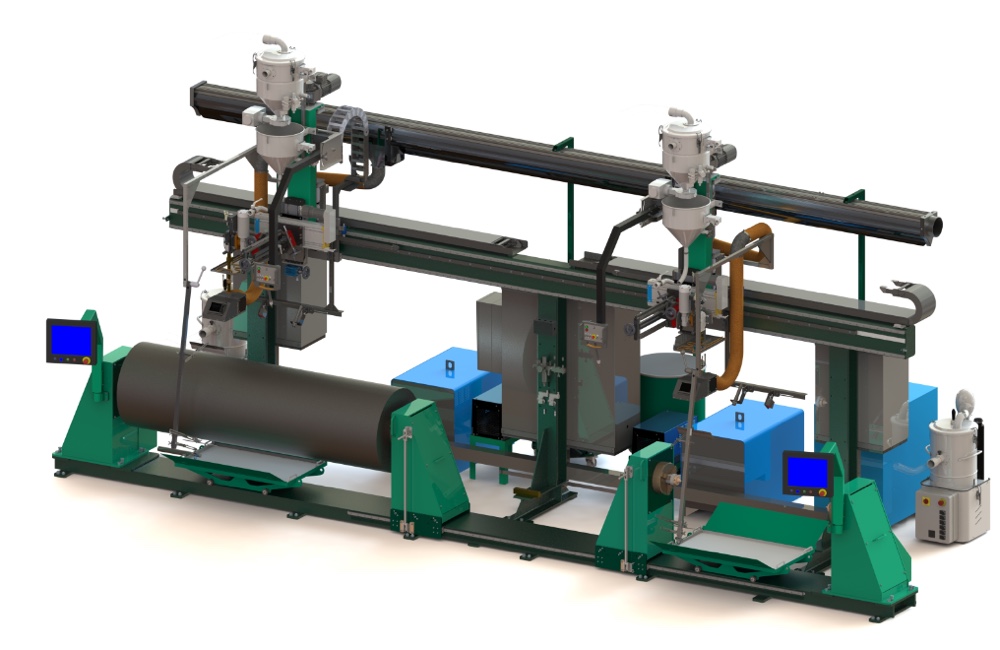

1. Roller Cladding machine is a heavy duty weld cladding and hardfacing machine. DESAN Welding offers a large range of Roller Cladding machines for welding rolls from 1 tonne, up to more than 50 tonnes.

Roller Cladding can be equipped with one, two, or more heads for welding one or two rolls at a time. Robust design and advanced technology makes our machines reliable and easy to use.

Industries: Steel and General Maintenance Workshops

Roller Cladding Characteristics

- HMI touch system;

- Multiple weld pattern: oscillating beads, stringer beads, square waves, chevron shape and spiral welding.

Roller Cladding machines Options: data logger, flux recovery system, Auto Stick-out Adjustment, temperature & dimension measurement, fume filtration, email error notifications.

Benefits

- Repeatable programming

- High quality weld deposits

- High productivity in manufacturing

- Minimal labour required

- Identification of operators

- Recording of welding parameters

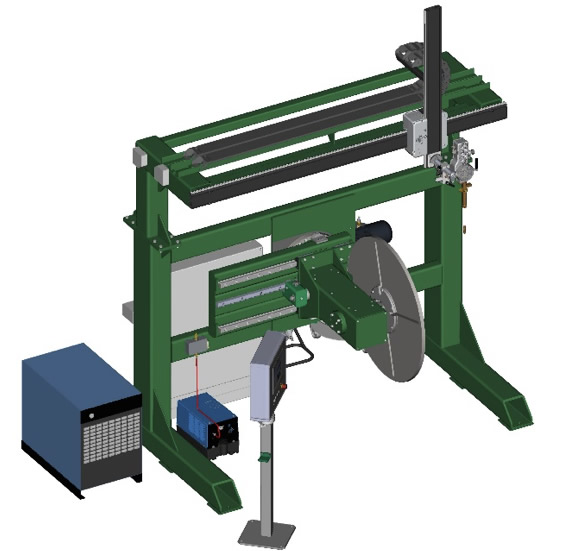

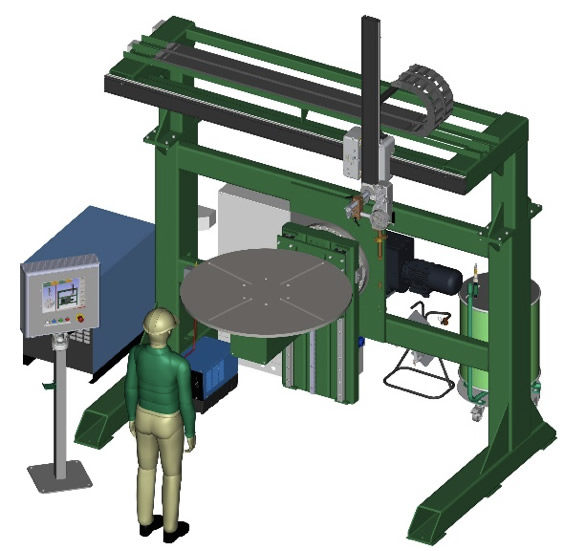

2. One machine for multiple directions

Roller Cladding is a heavy duty welded base assembly allowing welding of different components in all directions. DESAN control system is available on the machine, allowing fast and easy weld set up of different components, while maintaining precise control over the complete welding process.

Industries: oil and gas, forging, public works, repair and maintenance, and more.

Characteristics

- Heavy duty frame

- HMI Control system

- Four-axis machine

- Multiple weld patterns: oscillating beads, stringer beads and spiral

- Motors with encoders

- Automatic stick-out length adjustment

- Adjustable plate

Benefits

- Repeatable programming

- Constant surface speed

- Constant and precise motor control

- High quality weld deposits

- Suitable with a wide range of parts

|

|

In the surfacing welding industry hope you become our partner,