WELD MANIPULATOR WM4040 main parameter :

1.Summarize:

-

Column-boom WM4040 (movable and revolve) 1 set

- KB-10 Seam Tracker(optional) 1 set

- DC-1000welding system (optional) 1 set

- Flux send and recovery system 1 set

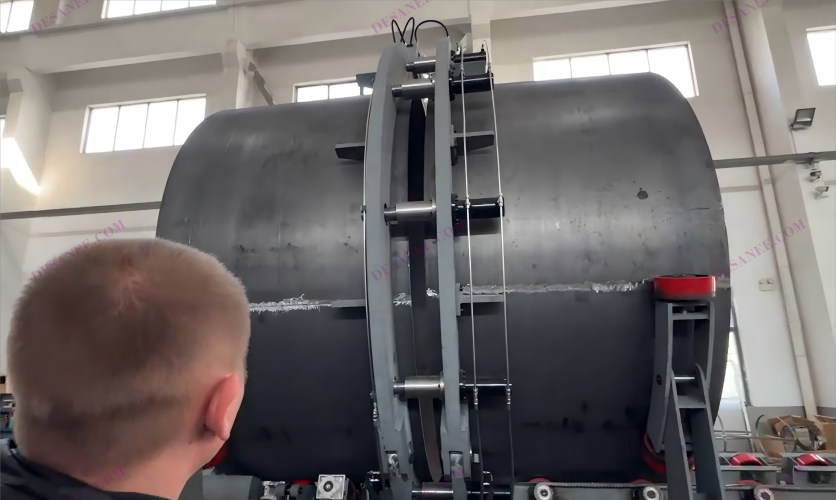

- SAR20 welding rotator 1 set (1P+1I)

2.Technical data

Column-boom: WELD MANIPULATOR WM4040

Structure: movable and revolve

Applicable vessel D: Φ630~4000 mm

Boom travel stroke: 4000 mm

Boom travel speed: 100-2000 mm/min (inverter)

Boom elevation stroke:4000 mm

Boom elevation speed: 1050 mm/min

Column motor-driven revolve angle: ±180°

Column manual revolve speed: manual

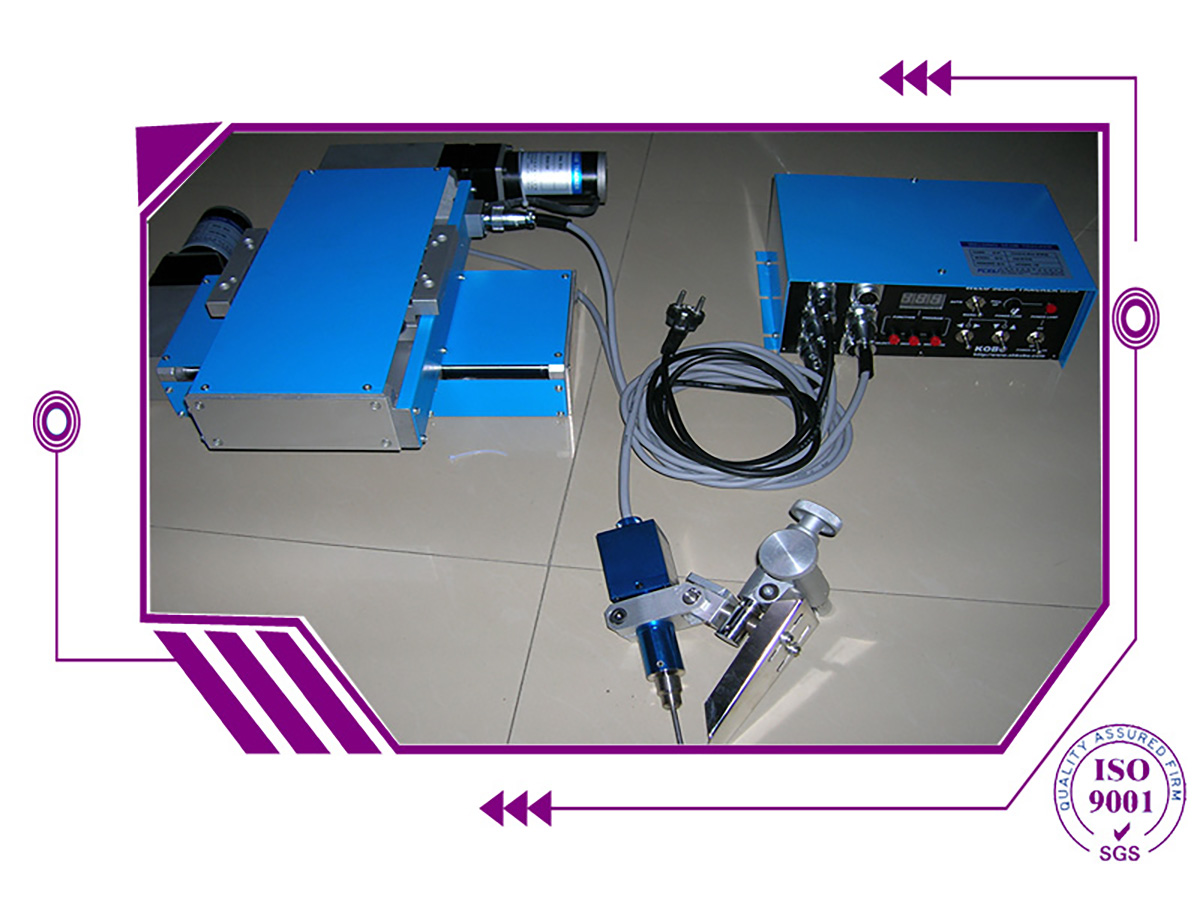

Seam-tracker:for weld MANIPULATOR

Model: KB-10

Testing range: 100 mm

Testing speed: 200 mm/min

Testing precision: ±0.3 mm

Loading: 100 kg

Power: AC220V

DC1000 SAW power with control box and wire feeder.

(CHINA AOTAI)

Rated welding current: 1000A

Idle voltage: 75V

Duty cycle:100%

Current range: 200~1000A

Wire D: 3~6 mm

Welding speed: 15~75 m/h

WELD MANIPULATOR WM4040 (manipulator) is used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

Welding rotator can apply in weld MANIPULATOR

3. Structure characteristics

This welding center mainly consists of column-boom、SAW and electric system.

3.1 Column-boom

(1)This column-boom is mainly composed of:boom-elevate unit、boom travel unit、column revolve unit、movable trolley、cross-slides、column、boom、trolley、worktable and electric system;

(2) Both column and boom are rectangular-section beams, with double-rail, which is welded into shape、stress-relieved and mechanical machined finely, ensuring higher

precision;

(3)Boom-elevate unit is installed at column-top, composed of A.C. braking motor、reducer、chain and sprocket. It has counter-balance, making stable boom elevation. To prevent chains from incidental broken, ratchet-type anti-dripping unit on the column is used for safe and reliable operation.

(4) There are 8 sets of control rollers on the saddle along vertical and horizontal movement. Each set has 3 control rollers. These control rollers are contacted with rails of boom and column through 3-sides, of adjustable eccentric structure, with great loading capacity, making good contact between them and rail surface, ensuring smooth and no

shivering boom travel;

(5) Boom travel is realized with A.C. inverter motor through worm-gear reducer

driving gear-rack. Its speed can be adjusted within 100-2000mm/min through inverter,

(6) Column is fit onto trolley through heavy-duty cross-roll bearing. Column can be revolved within ±180° manual